High efficiency round insert milling cutter

Round insert milling cutter with serrated inserts for superior chatter stability

Applications & Features

Applications

Features

Exceptionally improved chatter resistance

- The serrated cutting edges produce smaller chips.

- Reduced chatter even when machining with a long overhang.

Inserts & Grades

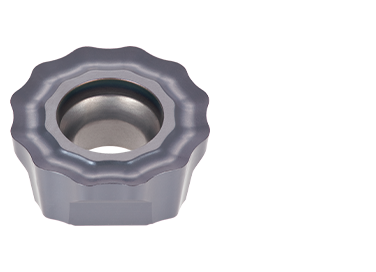

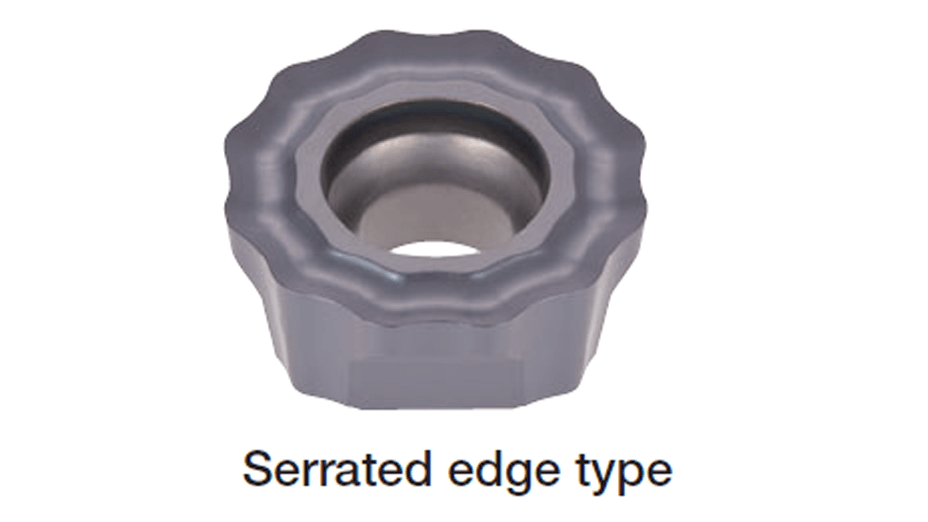

Inserts

Grades

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

AH140

![]()

- High fracture resistance

- Suitable for milling stainless steel

Cutter bodies

Practical examples

Example #1

| Workpiece type: | Die & mold parts |

| Material: | S50C / C50 |

| Cutter: | TRC12R050M22.0-05 (ø50 mm, CICT = 5) |

| Insert: | RCMT1204EN-NMJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 220 (m/min) fz = 0.09 (mm/t) ap = 5.5 (mm) ae = 32 (mm) Application: Shoulder milling Coolant: Dry Machine: Vertical M/C, BT40 |

Standard cutting conditions

| ISO | Workpiece material | Hardness HB |

Priority | Grade | Cutting speed Vc (m/min) |

Feed per tooth: fz (mm/t) each chipbreaker |

||

|---|---|---|---|---|---|---|---|---|

| MJ | NMJ | NAJ | ||||||

| Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

– 200 | First choice | AH3135 | 100 – 200 | 0.2 – 0.7 | 0.17 – 0.3 | – | |

| For wear resistance | AH120 | |||||||

| High carbon steels S45C, S55C, etc. C45, C55, etc. |

200 – 300 | First choice | AH3135 | 100 – 200 | 0.2 – 0.7 | 0.17 – 0.25 | – | |

| For wear resistance | AH120 | |||||||

| Alloyed steels SCM440, SCr415, etc. 42CrMo4, 20Cr4, etc. |

150 ~ 300 | First choice | AH3135 | 100 – 200 | 0.2 – 0.7 | 0.17 – 0.25 | – | |

| For wear resistance | AH120 | |||||||

| Tool steels SK, SKH, etc. X40CrMoV5-1, etc. |

– 300 | First choice | AH3135 | 100 – 180 | 0.2 – 0.7 | 0.17 – 0.25 | – | |

| For wear resistance | AH120 | |||||||

| Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– | First choice | AH3135 | 90 – 180 | 0.2 – 0.6 | 0.15 – 0.25 | – | |

| For impact resistance | AH140 | |||||||

| Grey cast irons FC250, FC300, etc. 250, 300, etc. |

150 – 250 | First choice | AH3135 | 140 – 250 | 0.2 – 0.7 | 0.17 – 0.3 | – | |

| For wear resistance | AH120 | |||||||

| Ductile cast irons FCD400, etc. 400-15S, etc. |

150 – 250 | First choice | AH3135 | 140 – 250 | 0.2 – 0.7 | 0.17 – 0.3 | – | |

| For wear resistance | AH120 | |||||||

| Aluminium alloys Si < 13% |

– | – | KS15F | 500 – 1200 | – | – | 0.1 – 0.3 | |

| Aluminium alloys Si ≥ 13% |

– | – | KS15F | 100 – 300 | – | – | 0.1 – 0.3 | |

| Heat-resistant alloy Inconel 718, Ti-6Al-4V, etc. |

– | First choice | AH3135 | 20 – 50 | 0.2 – 0.6 | 0.15 – 0.25 | – | |

| For wear resistance | AH725 | |||||||

For more information about this product, visit our online e-catalog or download the product report: