Radius cutter for profile milling of complex parts

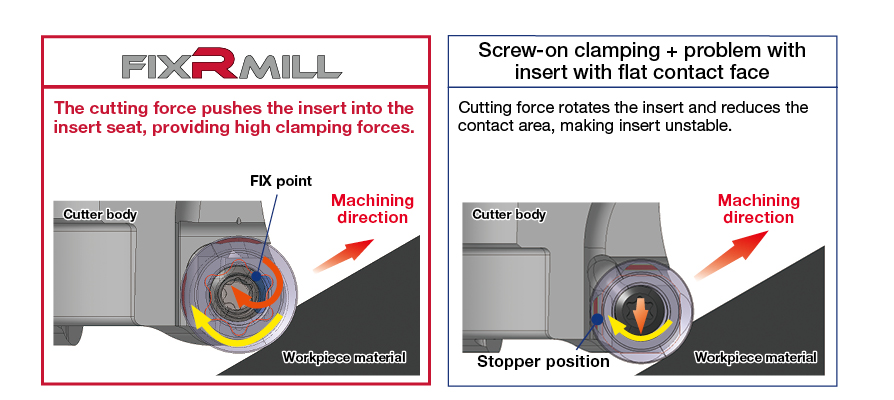

Innovative and safe anti-rotation system, featuring FIX insert location provides highly rigid clamping

Applications & Features

Applications

Features

1. Anti-rotation system with rigid clamping

• Secure insert seating on protrusion of cutter body.

• Cutting force pushing insert towards pocket, resulting in rigid clamping.

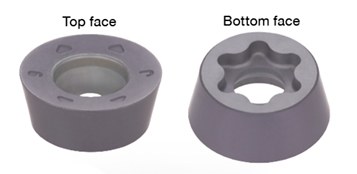

2. Round insert with 6 indexes

• No need to take off screw to change cutting-edges.

3. High-cutting speed Vc up to 300 m/min (984 sfm)

Inserts & Grades

Inserts

RPMT-MJ / -ML

- The unique insert fixation in the pocket allows up to 6 indexes.

- Two types of chipbreakers are available:

- MJ: General purpose machining

- ML: Low cutting force machining

Grades

AH725

![]()

![]()

- For general purpose milling

- Provides high reliability in steel and cast iron machining

- Highly versatile grade with excellent wear and chipping resistance

AH130

![]()

- For general stainless steel milling

- Reduces crater and notch wear

- Provides exceptionally reliable milling

AH4035

![]()

- Ideal grade for high chromium content stainless steels

- Newly developed grade with exceptional balance of wear and chipping resistance

- Drastically reduces flank wear and chipping when machining stainless steels

Cutter bodies

Shank Type

ERP (ø20 – ø40mm)

FixRMill radius cutter series shank type with Anti-Rotation System

Modular Type

HRP-M (ø20 – ø32mm)

Radius cutter series modular type (TungFlex) with Anti-Rotation System

Bore Type

TRP (ø40 – ø66mm)

FixRMill radius cutter series bore type with Anti-Rotation System

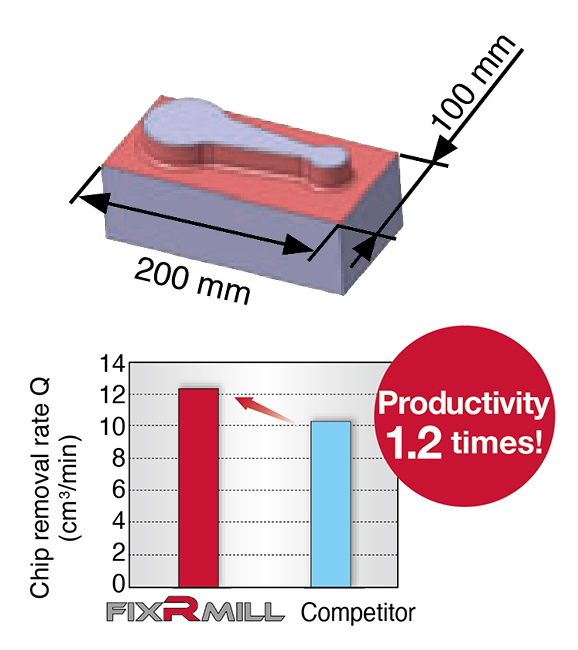

Practical examples

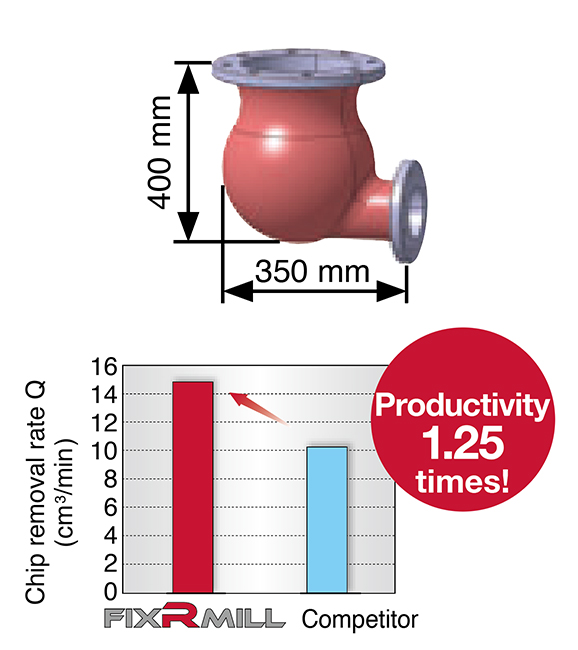

Example #1

Die and Mold Industry

| Part: | Die |

| Material: | SKD61 / X40CrMoV5-1 |

| Cutter: | ERP12R032M32.0-03 |

| Insert: | RPMT1204EN-ML |

| Grade: | AH725 |

| Cutting conditions: | Vc = 130 (m/min) fz = 0.4 (mm/t) ap = 1.0 (mm) ae = 26.0 (mm) Application: Profile milling Coolant: Air blast Machine: Vertical M/C, BT40 |

Example #2

General Engineering

| Part: | Machine part |

| Material: | Corrosion-resistant stainless steel |

| Cutter: | TRP12R050M22.0E05 |

| Insert: | RPMT1204EN-ML |

| Grade: | AH130 |

| Cutting conditions: | Vc = 200 (m/min) fz = 0.3 (mm/t) ap = 1.0 (mm) ae = < 50 (mm) Application: Profile milling on curved surface Coolant: Wet Machine: 5 axis M/C, BT50 |

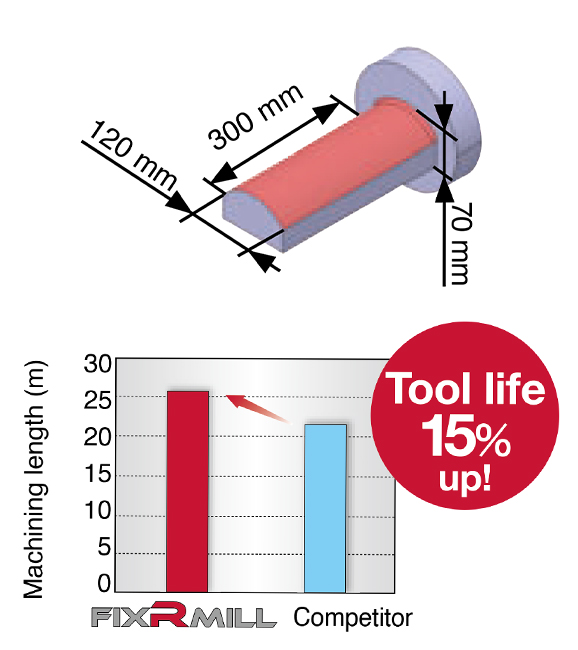

Example #3

General Engineering

| Part: | Machine part |

| Material: | SUS420J1 / X20Cr13 |

| Cutter: | TRP12R050M22.0E05 |

| Insert: | RPMT1204EN-MJ |

| Grade: | AH4035 |

| Cutting conditions: | Vc = 300 (m/min) fz = 0.5 (mm/t) ap = 2.0 (mm) ae = < 50 (mm) Application: Profile milling on curved surface Coolant: Air blast Machine: 5 axis M/C, BT50 |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Priority | Grade | Chip- breaker |

Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

Tool dia.: øDc (mm), Number of revolutions: n (min-1), Feed speed: Vf (mm/min), Depth of cut: ap = 2.0 mm | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ø20 | ø25 | ø32 | ø35 | ø40 | ø50 | ø63 | |||||||||||||||||||

| n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | ||||||||||||

| E/HRP10 | E/HRP10, E/HRP12 | E/HRP10 | E/HRP12 | ERP10 | TRP10 | ERP12 | ERP16 | ERP12 | TRP12 | TRP16 | |||||||||||||||

| Carbon steels (S45C / C45, S55C / C55 etc.) |

< 300 HB | First choice | AH725 | MJ | 120 – 250 | 0.3 – 0.7 | 2870 | 2870 | 2290 | 2290 | 1790 | 3580 | 2690 | 1640 | 3280 | 1430 | 3580 | 2860 | 1430 | 1150 | 2880 | 910 | 2730 | 2280 | |

| Vc = 180 m/min, fz = 0.5 mm/t | |||||||||||||||||||||||||

| < 300 HB | for impact resistance | AH130 | MJ | 120 – 250 | 0.3 – 0.7 | 2870 | 2870 | 2290 | 2290 | 1790 | 3580 | 2690 | 1640 | 3280 | 1430 | 3580 | 2860 | 1430 | 1150 | 2880 | 910 | 2730 | 2280 | ||

| Vc = 180 m/min, fz = 0.5 mm/t | |||||||||||||||||||||||||

| Alloy steels (SCM440 / 42CrMo4, SCr415 / 17Cr3 etc.) |

150 – 300 HB | First choice | AH725 | MJ | 100 – 250 | 0.2 – 0.6 | 2710 | 2160 | 2170 | 1740 | 1690 | 2700 | 2030 | 1550 | 2480 | 1350 | 2700 | 2160 | 1080 | 1080 | 2160 | 860 | 2060 | 1720 | |

| Vc = 170 m/min, fz = 0.4 mm/t | |||||||||||||||||||||||||

| 150 – 300 HB | for impact resistance | AH130 | MJ | 100 – 250 | 0.2 – 0.6 | 2710 | 2160 | 2170 | 1740 | 1690 | 2700 | 2030 | 1550 | 2480 | 1350 | 2700 | 2160 | 1080 | 1080 | 2160 | 860 | 2060 | 1720 | ||

| Vc = 170 m/min, fz = 0.4 mm/t | |||||||||||||||||||||||||

| Tool steels (SKD11 / X153CrMoV12 etc.) |

< 300 HB | – | AH725 | ML | 80 – 180 | 0.2 – 0.4 | 2070 | 1240 | 1660 | 1000 | 1290 | 1550 | 1160 | 1180 | 1420 | 1030 | 1550 | 1240 | 620 | 830 | 1250 | 660 | 1190 | 990 | |

| Vc = 130 m/min, fz = 0.3 mm/t | |||||||||||||||||||||||||

| Stainless steels (SUS304 / X5CrNi18-9, SUS316 / X5CrNiMo17-12-3 etc.) |

< 200 HB | First choice | AH130 | ML | 100 – 250 | 0.2 – 0.6 | 2710 | 2160 | 2170 | 1740 | 1690 | 2700 | 2030 | 1550 | 2480 | 1350 | 2700 | 2160 | 1080 | 1080 | 2160 | 860 | 2060 | 1720 | |

| Vc = 170 m/min, fz = 0.4 mm/t | |||||||||||||||||||||||||

| < 200 HB | for impact resistance | AH130 | MJ | 100 – 250 | 0.2 – 0.6 | 2710 | 2160 | 2170 | 1740 | 1690 | 2700 | 2030 | 1550 | 2480 | 1350 | 2700 | 2160 | 1080 | 1080 | 2160 | 860 | 2060 | 1720 | ||

| Vc = 170 m/min, fz = 0.4 mm/t | |||||||||||||||||||||||||

| Stainless steels (SUS430 / X6Cr17 etc.) |

< 200 HB | First choice | AH4035 | ML | 100 – 300 | 0.2 – 0.6 | 3180 | 2540 | 2550 | 2040 | 1990 | 3180 | 2390 | 1820 | 2910 | 1590 | 3180 | 2540 | 1270 | 1270 | 2540 | 1010 | 2420 | 2020 | |

| Vc = 200 m/min, fz = 0.4 mm/t | |||||||||||||||||||||||||

| < 200 HB | for impact resistance | AH4035 | MJ | 100 – 300 | 0.2 – 0.6 | 3180 | 2540 | 2550 | 2040 | 1990 | 3180 | 2390 | 1820 | 2910 | 1590 | 3180 | 2540 | 1270 | 1270 | 2540 | 1010 | 2420 | 2020 | ||

| Vc = 200 m/min, fz = 0.4 mm/t | |||||||||||||||||||||||||

| Grey cast irons (FC250 / GG25 / 250 etc.) |

150 – 250 HB | – | AH725 | ML | 120 – 250 | 0.3 – 0.7 | 2870 | 2870 | 2290 | 2290 | 1790 | 3580 | 2690 | 1640 | 3280 | 1430 | 3580 | 2860 | 1430 | 1150 | 2880 | 910 | 2730 | 2280 | |

| Vc = 180 m/min, fz = 0.5 mm/t | |||||||||||||||||||||||||

| Ductile cast irons (FCD400 / GGG40 etc.) |

150 – 250 HB | – | AH725 | ML | 100 – 200 | 0.3 – 0.7 | 2390 | 2390 | 1910 | 1910 | 1490 | 2980 | 2240 | 1360 | 2720 | 1190 | 2980 | 2380 | 1190 | 950 | 2380 | 760 | 2280 | 1900 | |

| Vc = 150 m/min, fz = 0.5 mm/t | |||||||||||||||||||||||||

| Hardened steels (SKD61 / X40CrMoV5-1 etc.) |

40 – 50 HRC | – | AH725 | MJ | 60 – 140 | 0.1 – 0.3 | 1590 | 630 | 1270 | 510 | 990 | 790 | 590 | 910 | 730 | 800 | 800 | 640 | 320 | 640 | 640 | 510 | 610 | 510 | |

| Vc = 100 m/min, fz = 0.2 mm/t | |||||||||||||||||||||||||

| Hardened steels (SKD11 / X153CrMoV12 etc.) |

50 – 60 HRC | – | AH725 | MJ | 20 – 60 | 0.05 – 0.2 | 640 | 150 | 510 | 120 | 400 | 190 | 140 | 360 | 170 | 320 | 190 | 150 | 75 | 250 | 150 | 200 | 140 | 120 | |

| Vc = 40 m/min, fz = 0.12 mm/t | |||||||||||||||||||||||||

For more information about this product, visit our online e-catalog or download the product report: