High feed milling cutters with six cutting edge inserts

Featuring robust cutter design for high productivity

Applications & Features

Applications

Features

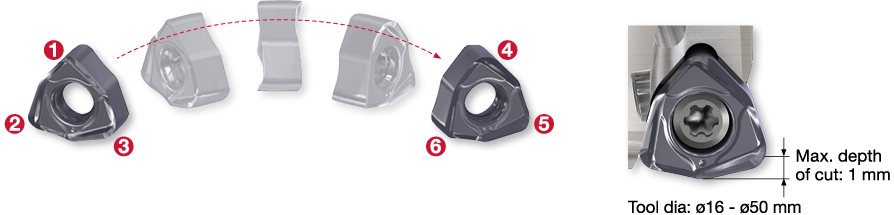

1. Economical double-sided inserts with six cutting edges

– 1.5 to 3 times greater number of cutting edges per insert compared with conventional high feed milling inserts.

– Reduced cost per insert when machining stainless steels and difficult materials, where inserts demonstrate rapid wear.

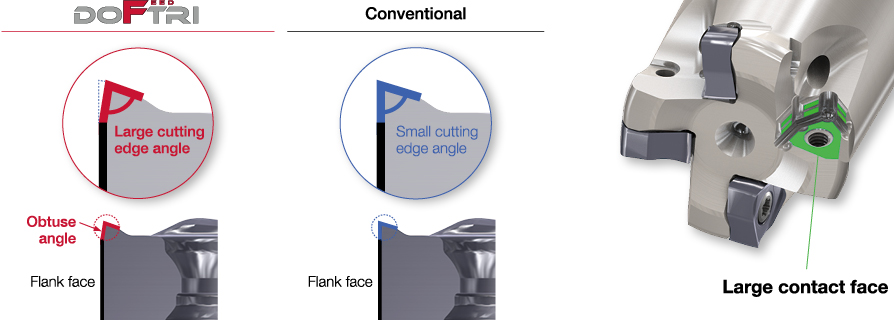

2. Designed for tool reliability and stability

– Robust cutting edge design forms an obtuse angle, eliminating insert fracture during machining.

– A large contact face on the insert seat provides secure insert retention.

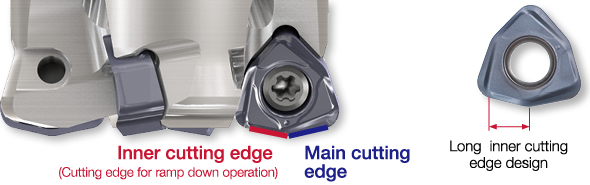

3. Excellent ramping capability

– Longer inner cutting edge allows higher ramp-down capabilities to promote higher productivity.

– Increased max ramping angles allow productivity boosts in linear and helical ramping operations.

Inserts & Grades

Inserts

Main Grades

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

AH8015

![]()

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

Cutter bodies

Practical examples

Example #1

| Part: | Machine structural part |

| Material: | SS400 / E275A |

| Cutter: | EXWX03M020C20.0R03 (ø20 mm, z = 3) |

| Insert: | WXMU0303ZER-MM |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 180 (m/min) fz = 0.9 (mm/t) ap = 0.5 (mm) ae = 20 (mm) Application: Slotting, Shoulder milling Coolant: Dry Machine: Vertical M/C, BT40 |

Example #2

| Part: | Heavy equipment part |

| Material: | SM400 / E235A |

| Cutter: | EXWX03U1.00C1.00R04 (ø25.4 mm, z = 4) |

| Insert: | WXMU0303ZER-MM |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 255 (m/min) fz = 0.28 (mm/t) ap = 1 (mm) ae = 25.4 (mm) Application: Hole enlarging Coolant: Wet Machine: Vertical M/C, CAT40 |

Example #3

| Part: | Machine part |

| Material: | S45C / C45 |

| Cutter: | EXWX03M025C25.0R04 (ø25 mm, z = 4) |

| Insert: | WXMU0303ZER-MM |

| Grade: | AH3225 |

| Cutting conditions: | Vc = 200 (m/min) fz = 0.3 (mm/t) ap = 0.5 (mm) ae = 25 (mm) Application: Slotting, Shoulder milling Coolant: Dry Machine: Vertical M/C, BT40 |

Standard cutting conditions

Insert size 03

| ISO | Workpiece materials | Hardness | Priority | Grades | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

Tool diameter: DCX (mm), Number of revolution: n (min-1), Feed speed: Vf (mm/min), Max. depth of cut: APMX = 1 mm, Number of teeth: CICT | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ø16, CICT = 2 | ø20, CICT = 3 | ø25, CICT = 4 | ø32, CICT = 5 | ø40, CICT = 6 | ø50, CICT = 8 | |||||||||||||||

| n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | |||||||||

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 300HB | First choice | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | 3,981 | 7,962 | 3,185 | 9,554 | 2,548 | 10,191 | 1,990 | 9,952 | 1,592 | 9,554 | 1,274 | 10,191 | |

| For wear resistance | AH8015 | |||||||||||||||||||

| Low cutting force | AH3225 | ML | 0.5 – 1.2 | Vc = 200 m/min, fz = 1 mm/t | ||||||||||||||||

| Carbon steel, Alloy steel S55C, SCM440, etc. C55, 42CrMoS4, etc. |

– 300HB | First choice | AH3225 | MM | 100 – 250 | 0.5 – 1.5 | 3,981 | 7,962 | 3,185 | 9,554 | 2,548 | 10,191 | 1,990 | 9,952 | 1,592 | 9,554 | 1,274 | 10,191 | ||

| For wear resistance | AH8015 | |||||||||||||||||||

| Low cutting force | AH3225 | ML | 0.5 – 1.2 | Vc = 200 m/min, fz = 1 mm/t | ||||||||||||||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40HRC | First choice | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | 2,986 | 4,180 | 2,389 | 5,016 | 1,911 | 5,350 | 1,493 | 5,225 | 1,194 | 5,016 | 955 | 5,350 | ||

| For wear resistance | AH8015 | |||||||||||||||||||

| Low cutting force | AH3225 | ML | 0.5 – 1 | Vc = 150 m/min, fz = 0.7 mm/t | ||||||||||||||||

|

Austenitic Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200HB | First choice | AH130 | MS | 80 – 150 | 0.5 – 1 | 2,389 | 2,389 | 1,911 | 2,866 | 1,529 | 3,057 | 1,194 | 2,986 | 955 | 2,866 | 764 | 3,057 | |

| Low cutting force | AH130 | ML | 0.5 – 0.8 | Vc = 120 m/min, fz = 0.5 mm/t | ||||||||||||||||

| Martensitic Stainless steel SUS410, SUS420J1, etc. X12Cr13, X20Cr13, etc. |

– 200HB | First choice | AH130 | MS | 50 – 120 | 0.3 – 1 | 1,990 | 1,194 | 1,592 | 1,433 | 1,274 | 1,529 | 995 | 1,493 | 796 | 1,433 | 637 | 1,529 | ||

| Low cutting force | AH130 | ML | 0.3 – 0.8 | Vc = 100 m/min, fz = 0.3 mm/t | ||||||||||||||||

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | 3,981 | 7,962 | 3,185 | 9,554 | 2,548 | 10,191 | 1,990 | 9,952 | 1,592 | 9,554 | 1,274 | 10,191 | |

| For impact resistance | AH3225 | |||||||||||||||||||

| Low cutting force | AH8015 | ML | 0.5 – 1.2 | Vc = 200 m/min, fz = 1 mm/t | ||||||||||||||||

| Ductile cast iron FCD400, etc. 400-15, 600-3, etc. |

150 – 250HB | First choice | AH8015 | MM | 80 – 200 | 0.5 – 1.5 | 2,986 | 5,971 | 2,389 | 7,166 | 1,911 | 7,643 | 1,493 | 7,464 | 1,194 | 7,166 | 955 | 7,643 | ||

| For impact resistance | AH3225 | |||||||||||||||||||

| Low cutting force | AH8015 | ML | 0.5 – 1.2 | Vc = 150 m/min, fz = 1 mm/t | ||||||||||||||||

|

Titanium alloy Ti-6AI-4V, etc. |

– 40HRC | First choice | AH130 | MS | 30 – 60 | 0.3 – 0.7 | 796 | 637 | 637 | 764 | 510 | 815 | 398 | 796 | 318 | 764 | 255 | 815 | |

| For impact resistance | AH130 | MM | Vc = 40 m/min, fz = 0.4 mm/t | |||||||||||||||||

| Superalloys Inconel718, etc. |

– 40HRC | First choice | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | 597 | 239 | 478 | 287 | 382 | 306 | 299 | 299 | 239 | 287 | 191 | 306 | ||

| Low cutting force | AH8015 | ML | 0.1 – 0.25 | Vc = 30 m/min, fz = 0.2 mm/t | ||||||||||||||||

|

Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 | MM | 80 – 150 | 0.1 – 0.5 | 2,389 | 1,433 | 1,911 | 1,720 | 1,529 | 1,834 | 1,194 | 1,791 | 955 | 1,720 | 764 | 1,834 |

| For impact resistance | AH3225 | Vc = 120 m/min, fz = 0.3 mm/t | ||||||||||||||||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 | MM | 50 – 70 | 0.03 – 0.1 | 1,194 | 239 | 955 | 287 | 764 | 306 | 597 | 299 | 478 | 287 | 382 | 306 | ||

| Vc = 60 m/min, fz = 0.1 mm/t | ||||||||||||||||||||

Insert size 06

| ISO | Workpiece materials | Hardness | Priority | Grades | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

Tool diameter: DCX (mm), Number of revolution: n (min-1), Feed speed: Vf (mm/min), Max. depth of cut: APMX = 1 mm, Number of teeth: CICT | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ø40, CICT = 4 | ø50, CICT = 4 | ø52, CICT = 6 | ø63, CICT = 5 | ø66, CICT = 7 | ø80, CICT = 8 | |||||||||||||||

| n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | |||||||||

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 300HB | First choice | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | 1,592 | 6,369 | 1,274 | 5,096 | 1,225 | 7,349 | 1,011 | 5,055 | 965 | 6,755 | 796 | 6,369 | |

| For wear resistance | AH8015 | Vc = 200 m/min, fz = 1 mm/t | ||||||||||||||||||

| Carbon steel, Alloy steel S55C, SCM440, etc. C55, 42CrMoS4, etc. |

– 300HB | First choice | AH3225 | MM | 100 – 250 | 0.5 – 1.5 | 1,592 | 6,369 | 1,274 | 5,096 | 1,225 | 7,349 | 1,011 | 5,055 | 965 | 6,755 | 796 | 6,369 | ||

| For wear resistance | AH8015 | Vc = 200 m/min, fz = 1 mm/t | ||||||||||||||||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40HRC | First choice | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | 1,592 | 6,369 | 1,274 | 5,096 | 1,225 | 7,349 | 1,011 | 5,055 | 965 | 6,755 | 796 | 6,369 | ||

| For wear resistance | AH8015 | Vc = 200 m/min, fz = 1 mm/t | ||||||||||||||||||

|

Austenitic Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200HB | First choice | AH3135 | MM | 80 – 150 | 0.5 – 1 | 955 | 1,911 | 764 | 1,529 | 735 | 2,205 | 607 | 1,517 | 579 | 2,027 | 478 | 1,911 | |

| Vc = 120 m/min, fz = 0.5 mm/t | ||||||||||||||||||||

| Martensitic Stainless steel SUS410, SUS420J1, etc. X12Cr13, X20Cr13, etc. |

– 200HB | First choice | AH3135 | MM | 50 – 120 | 0.3 – 1 | 796 | 955 | 637 | 764 | 612 | 1,102 | 506 | 758 | 483 | 1,013 | 398 | 955 | ||

| Vc = 100 m/min, fz = 0.3 mm/t | ||||||||||||||||||||

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | 1,592 | 6,369 | 1,274 | 5,096 | 1,225 | 7,349 | 1,011 | 5,055 | 965 | 6,755 | 796 | 6,369 | |

| For impact resistance | AH3225 | Vc = 200 m/min, fz = 1 mm/t | ||||||||||||||||||

| Ductile cast iron FCD400, etc. 400-15, 600-3, etc. |

150 – 250HB | First choice | AH8015 | MM | 80 – 200 | 0.5 – 1.5 | 1,194 | 4,777 | 955 | 3,822 | 919 | 5,512 | 758 | 3,791 | 724 | 5,067 | 597 | 4,777 | ||

| For impact resistance | AH3225 | Vc = 150 m/min, fz = 1 mm/t | ||||||||||||||||||

|

Titanium alloy Ti-6AI-4V, etc. |

– 40HRC | First choice | AH3135 | MM | 30 – 60 | 0.3 – 0.7 | 318 | 510 | 255 | 408 | 245 | 588 | 202 | 404 | 193 | 540 | 159 | 510 | |

| Vc = 40 m/min, fz = 0.4 mm/t | ||||||||||||||||||||

| Superalloys Inconel718, etc. |

– 40HRC | First choice | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | 239 | 191 | 191 | 153 | 184 | 220 | 152 | 152 | 145 | 203 | 119 | 191 | ||

| Vc = 30 m/min, fz = 0.2 mm/t | ||||||||||||||||||||

|

Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH8015 | MM | 80 – 150 | 0.1 – 0.5 | 955 | 1,146 | 764 | 917 | 735 | 1,323 | 607 | 910 | 579 | 1,216 | 478 | 1,146 |

| For impact resistance | AH3225 | Vc = 120 m/min, fz = 0.3 mm/t | ||||||||||||||||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 | MM | 50 – 70 | 0.03 – 0.1 | 478 | 191 | 382 | 153 | 367 | 220 | 303 | 152 | 290 | 203 | 239 | 191 | ||

| Vc = 60 m/min, fz = 0.1 mm/t | ||||||||||||||||||||

For more information about this product, visit our online e-catalog or download the product report: