Super high-feed face milling cutter with 8 cutting-edge insert

Double-sided insert with 8 cutting-edge helps reduce manufacturing cost

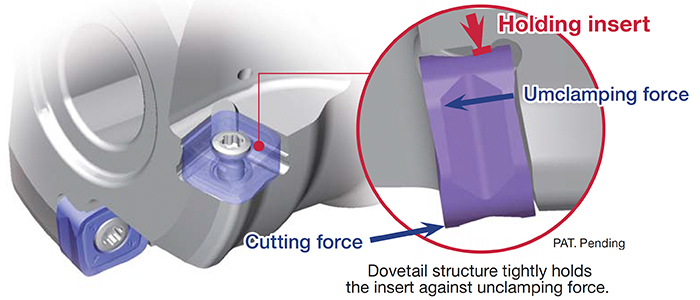

Also, dovetail structure on clamping firmly holds insert in high-feed milling, providing strong fracture resistance

Applications & Features

Applications

Features

1. Economical advantages

- Double sided insert with 8 corners for high feed milling.

2. Remarkable reliability in high feed milling

- Dovetail structure improves the clamping strength by 50%*. * Calculated with Finite Element Analysis (FEA)

- Rigid clamping with one screw.

- Simple structure offers a high level of cutter body rigidity with easy operation.

Inserts & Grades

Inserts

SQMU

- Max depth of cut: 2mm

- 8 corners double sided insert with MJ chipbreaker, low cutting force even in high feed cutting

Grades

AH725

![]()

![]()

![]()

- Newly developed coating layer with a unique substrate

- Well balanced with excellent wear and chipping resistance

- Suitable for steels

AH130

![]()

- Unique substrate

- Well balanced grade with hardness and toughness

- First choice for stainless steels

AH120

![]()

- Tough substrate with high reliability

- Outstanding wear resistance

- Ideal grade for cast iron milling

T3130

![]()

- Tough substrate with a highly adhered coating

- Thick coating for exceptional wear resistance

- Suitable for steels in high speed cutting

Cutter bodies

Practical examples

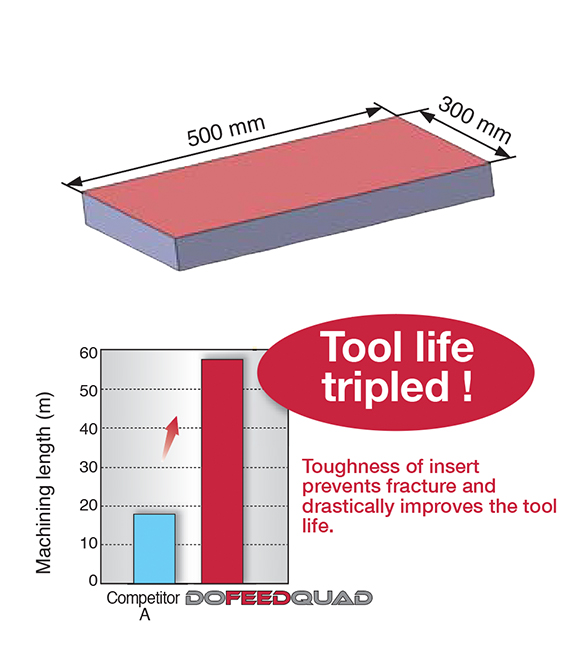

Example #1

General Engineering

| Part: | Plate |

| Material: | Prehardened steels (40HRC) |

| Cutter: | TXQ12R125M38.1-07 (ø125, z = 7) |

| Insert: | SQMU1206ZSR-MJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 80 (m/min) fz = 0.7 (mm/t) ap = 1.0 ~ 2.0 (mm) ae = 75 (mm) Application: Face milling Coolant: Dry Machine: Vertical M/C, BT50 |

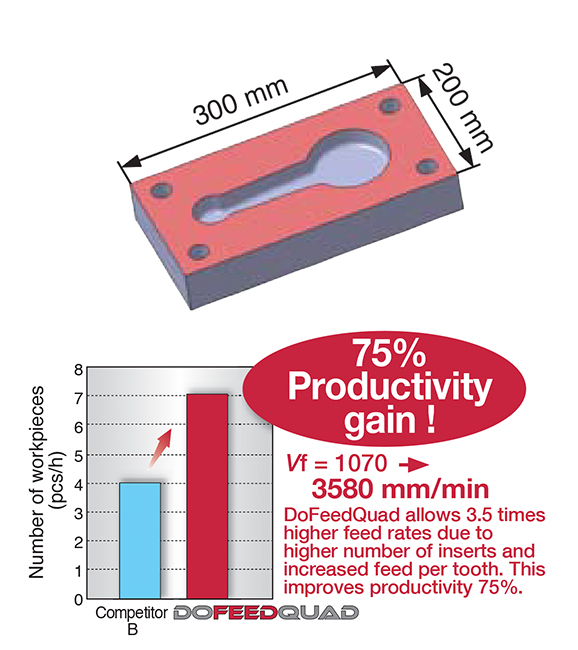

Example #2

General Engineering

| Part: | Machine part |

| Material: | SS400 / E275A |

| Cutter: | TXQ12R80M31.7-05 (ø80, z = 5) |

| Insert: | SQMU1206ZSR-MJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 180 (m/min) fz = 1.0 (mm/t) ap = 1.0 (mm) ae = 75 (mm) Application: Face milling Coolant: Dry Machine: Vertical M/C, BT50 |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report: