Face Milling Cutter with 8 Cutting Edge Insert for Ultimate Clearance

Milling cutter with 8 cornered insert for high utilization in face milling operations

Applications & Features

Applications

Features

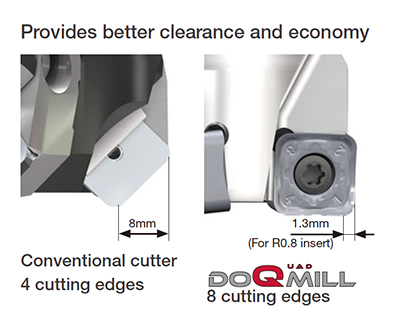

1. Face milling cutter with maximum clearance and economy

• Designed to avoid tool interference in rough and finish face milling operations.

• Wiper insert is also available for precision surface finish requirements.

2. Cutter design optimized for low cutting force and chattering prevention

• Stable cutting performance due to the concave shape cutting edges.

• Reinforced insert with resistance to fracture.

Inserts & Grades

Inserts

Main Grades

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

T1215

![]()

- Good balance between wear and chipping resistance

- Suitable for milling cast iron

T3225

![]()

![]()

- High chipping and fracture resistance

- Suitable for milling steel and stainless steel

Cutter bodies

Practical examples

Example #1

Automotive Industry

| Part: | Steering knuckle |

| Material: | FCD450 |

| Cutter: | THSN12M050B22.0R04 (ø50 mm, z = 4) |

| Insert: | SNMU120620EN-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 142 (m/min) fz = 0.22 (mm/t) Vf = 800 (mm/min) ap = 2 (mm) ae = 30 (mm) Application: Face milling Coolant: External Machine: Vertical M/C |

Example #2

Automotive Industry

| Part: | Shaft |

| Material: | Alloy steel (35HRC) |

| Cutter: | THSN12M050B22.0R04 (ø50 mm, z = 4) |

| Insert: | SNMU120620EN-MM |

| Grade: | AH3135 |

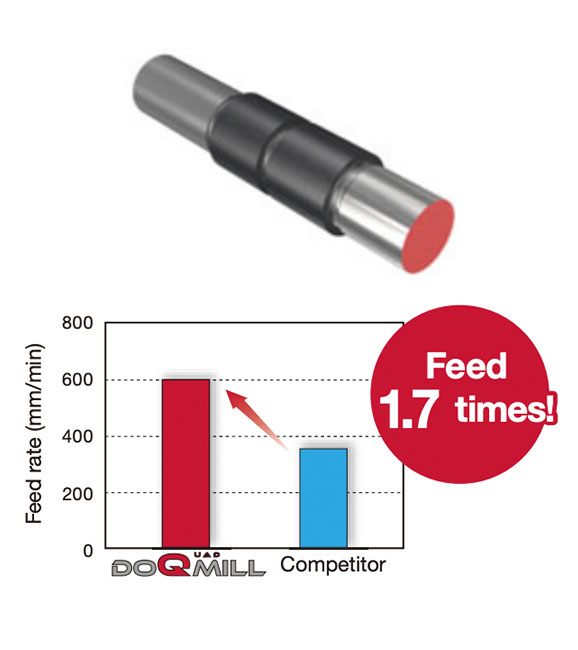

| Cutting conditions: | Vc = 236 (m/min) fz = 0.1 (mm/t) Vf = 600 (mm/min) ap = 2 (mm) ae = 35 (mm) Application: Face milling Coolant: External Machine: Vertical M/C |

Example #3

Automotive Industry

| Part: | Shaft |

| Material: | Alloy steel |

| Cutter: | THSN12M050B22.0R04 (ø50 mm, z = 4) |

| Insert: | SNMU120620EN-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 157 (m/min) fz = 0.2 (mm/t) Vf = 800 (mm/min) ap = 2 (mm) ae = 40 (mm) Application: Shoulder milling Coolant: External supply Machine: Vertical M/C |

Standard cutting conditions

| ISO | Workpiece materials | Hardness | Priority | Grades | Chip-breaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|

| Low carbon steels S15C, etc. C15E4, etc., C15E, etc. |

– 200HB | First choice | AH3225 | MM | 100 – 250 | 0.06 – 0.3 | |

| – 200HB | For wear resistance | T3225 | MM | 200 – 350 | 0.06 – 0.25 | ||

| High carbon and alloy steel S55C, SCM440, etc. C55, 42CrMo4, etc. |

– 300HB | First choice | AH3225 | MM | 100 – 250 | 0.06 – 0.3 | |

| – 300HB | For wear resistance | T3225 | MM | 180 – 300 | 0.06 – 0.25 | ||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MM | 100 – 200 | 0.06 – 0.25 | |

| 30 – 40 HRC | For wear resistance | T3225 | MM | 150 – 250 | 0.06 – 0.2 | ||

| Austenitic stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

– 200HB | First choice | AH3135 | MM | 100 – 200 | 0.06 – 0.25 | |

| – 200HB | For wear resistance | T3225 | MM | 100 – 200 | 0.06 – 0.2 | ||

| Stainless cast steel SCH20XNb, 1.4849, etc. |

– | First choice | T3225 | MM | 60 – 120 | 0.06 – 0.2 | |

| – | For fracture resistance | AH3135 | MM | 60 – 120 | 0.06 – 0.2 | ||

| Grey cast iron FC250, etc. 250, etc., GG25, etc. |

150 – 250HB | First choice | T1215 | MM | 100 – 350 | 0.06 – 0.3 | |

| 150 – 250HB | For fracture resistance | AH120 | MM | 100 – 250 | 0.06 – 0.3 | ||

| Ductile cast iron FCD600, etc. 600-3, etc., GGG60, etc. |

150 – 250HB | First choice | T1215 | MM | 100 – 350 | 0.06 – 0.25 | |

| 150 – 250HB | For fracture resistance | AH120 | MM | 80 – 200 | 0.06 – 0.3 | ||

| Titanium alloys Ti-6AI-4V, etc. |

– 40HRC | First choice | AH3135 | MM | 30 – 60 | 0.06 – 0.2 | |

| Heat-resistant alloys Inconel718, etc. |

– 40HRC | First choice | AH120 | MM | 10 – 40 | 0.04 – 0.16 | |

| Hardened steel SKD61, etc., X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH3225 | MM | 80 – 130 | 0.04 – 0.16 | |

| Hardened steel SKD11, etc., X153CrMoV12, etc. |

50 – 60HRC | First choice | AH120 | MM | 50 – 70 | 0.02 – 0.08 |

For more information about this product, visit our online e-catalog or download the product report: