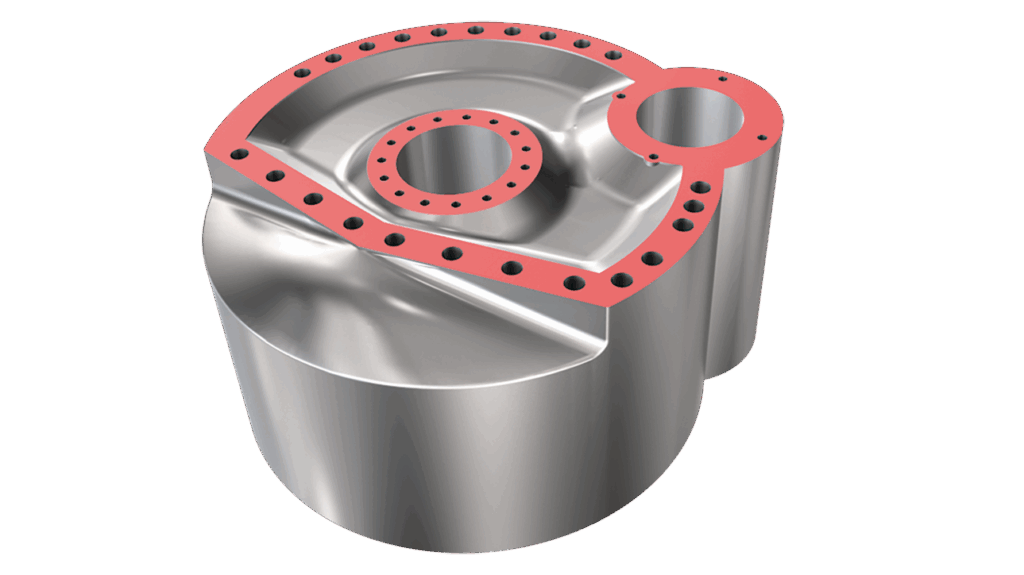

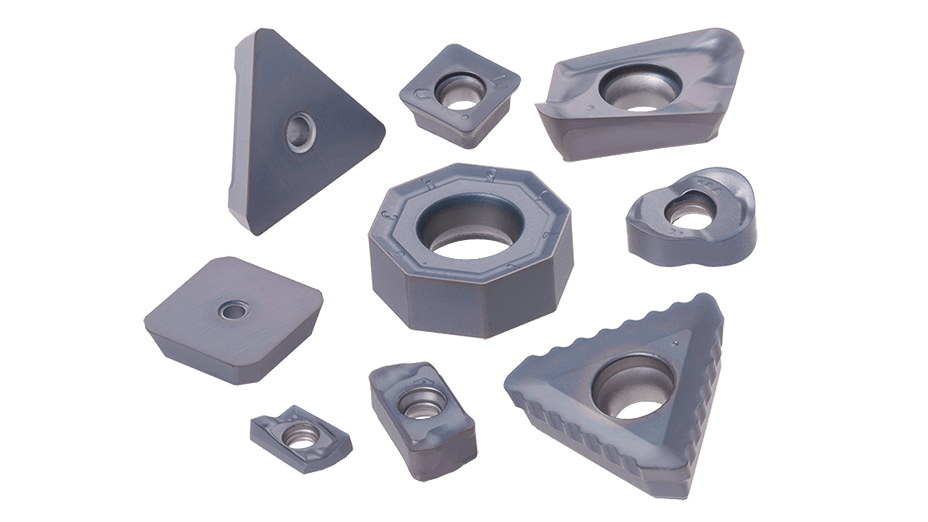

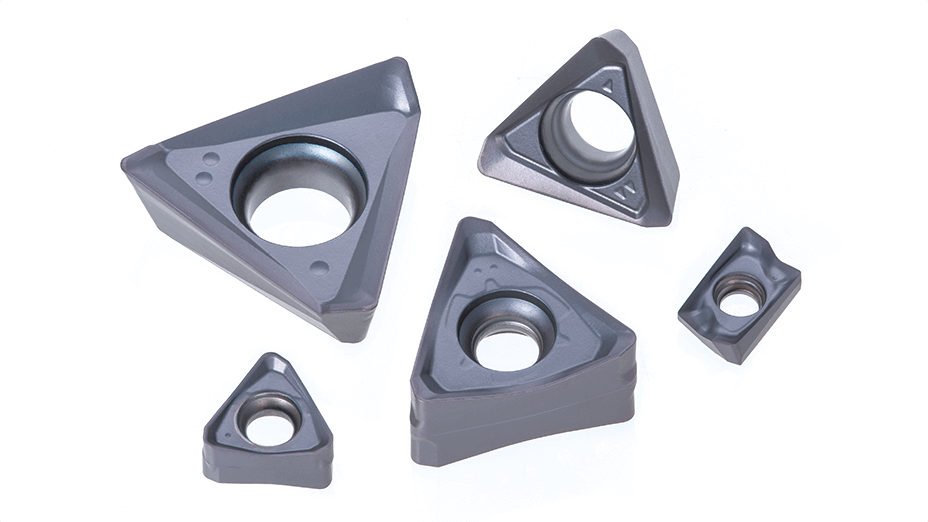

Iwaki, Japan – July 14, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its PVD-coated grade AH3225, now available for a broader range of milling tools including high-feed cutters (MillQuadFeed), face milling cutters (DoOcto), shoulder milling cutters (TungTriShred), and ISO insert shapes such as SDKN42** and TEEN32**.

Challenges and Trends

In general machining, automotive parts manufacturing, die and mold, and heavy electrical and industrial machinery sectors, there is a strong demand for extended tool life and improved machining efficiency in ISO P steel applications. In particular, extending tool life, which directly contributes to reducing manufacturing costs, is a critical issue in many production environments. However, under high-speed and high-load machining conditions, conventional grades tend to wear quickly, making stable machining difficult. As a result, there is a growing need for new grades with higher wear resistance.

Product Overview

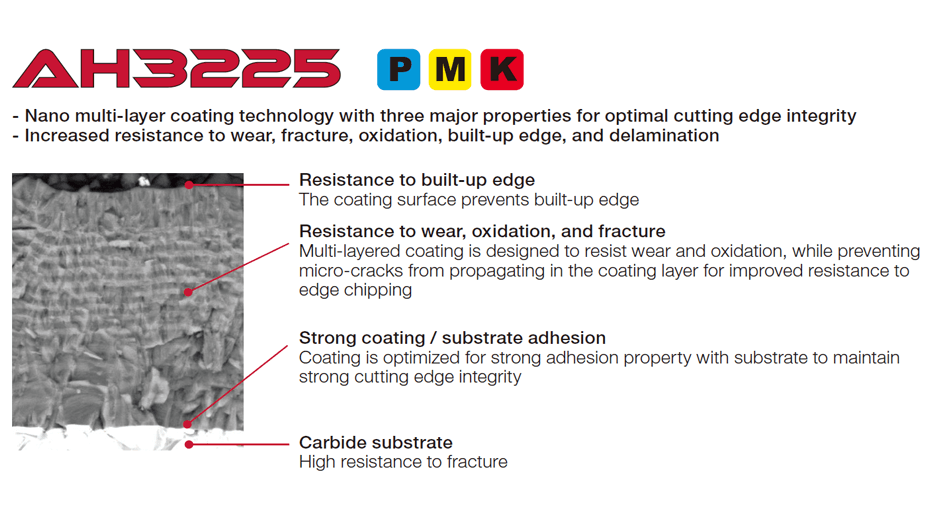

AH3225 is a PVD-coated grade that offers excellent wear resistance, fracture resistance, and oxidation resistance. Its unique “Triple Nano Coating” ensures long tool life and stable performance when machining steel and stainless steel.

Benefits and Features

Feature 1: Extended Tool Life and Stable Machining with Superior Wear Resistance

– AH3225 is a coated grade with excellent resistance to crater wear and flank wear.

– By suppressing wear progression, it extends tool life and reduces the frequency of tool changes.

– It minimizes dimensional variation and surface deterioration caused by wear, ensuring consistent machining quality.

Feature 2: Enhanced Productivity Under High Cutting Conditions

– AH3225 combines high wear resistance with excellent fracture resistance, enabling increased cutting speeds and feed rates.

– High-feed and high-speed machining can significantly reduce machining time and overall costs.

Feature 3: Expanded Range of Applications Through Compatibility with Various Tool Geometries

– AH3225 is available for a wide variety of tools including MillQuadFeed (high-feed tooling), DoOcto (face milling tools), and TungTriShred (shoulder milling tools), as well as ISO geometries such as SDKN42** and TEEN32**.

– This broad compatibility allows for greater flexibility in tool selection and provides optimal solutions tailored to each machining environment.

Cutting Performance

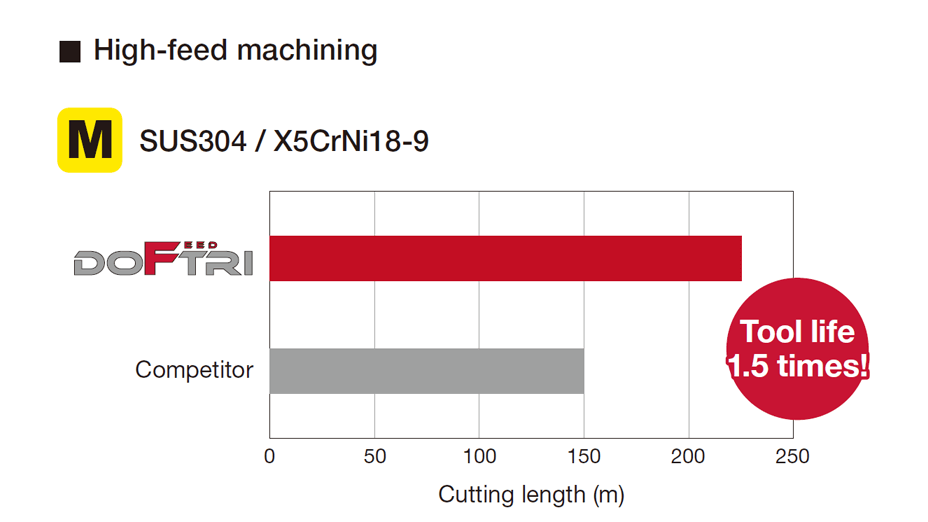

Tool Life Comparison

| Cutter | EXWX03M020C20.0R03 (⌀20 mm, CICT = 3) |

| Insert | WXMU0303ZER-MM AH3225 |

| Cutting speed | Vc = 120 m/min |

| Feed per tooth | fz = 0.7 mm/t |

| Depth of cut | ap = 0.6 mm |

| Width of cut | ae = 12 mm |

| Coolant | Wet |

| Machine | Vertical M/C, BT40 |

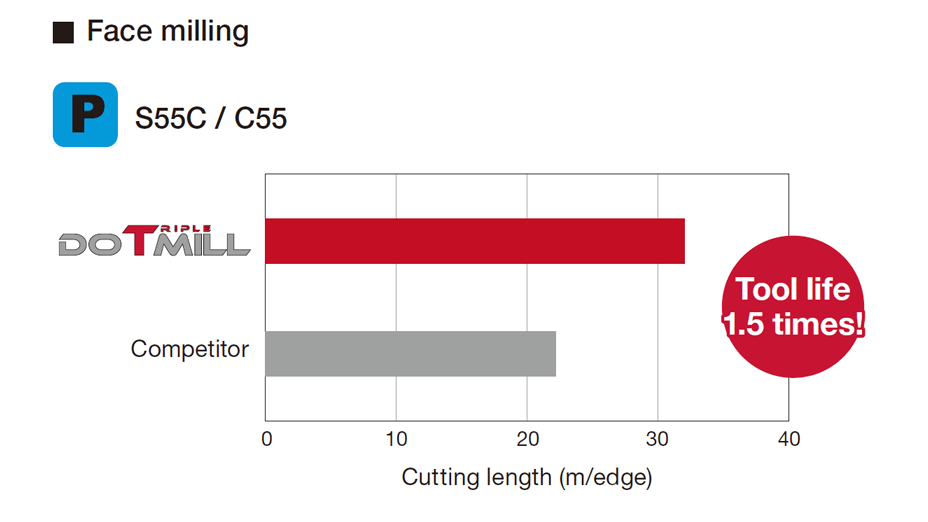

| Cutter | TASN13J080B25.4R05 (⌀80 mm, CICT = 5) |

| Insert | SNMU1307ANEN-MJ AH3225 |

| Cutting speed | Vc = 150 m/min |

| Feed per tooth | fz = 0.2 mm/t |

| Depth of cut | ap = 2 mm |

| Width of cut | ae = 50 mm |

| Coolant | Dry |

| Machine | Vertical M/C, BT40 |

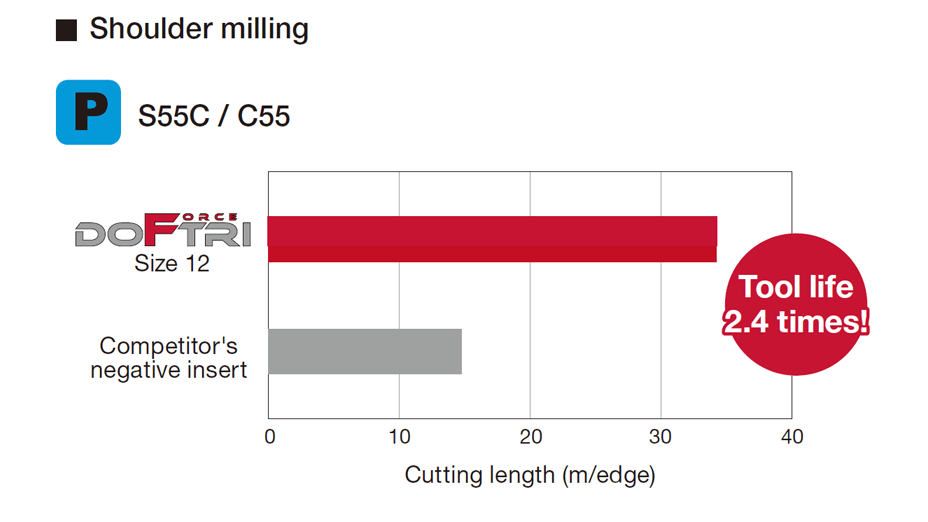

| Cutter | TPTN12M050B22.0R05 (⌀50 mm, CICT = 5) |

| Insert | TNMU120708PER-MJ AH3225 |

| Cutting speed | Vc = 200 m/min |

| Feed per tooth | fz = 0.15 mm/t |

| Depth of cut | ap = 3 mm |

| Width of cut | ae = 30 mm |

| Coolant | Dry |

| Machine | Vertical M/C, BT40 |

Success Stories

IMPROVED TOOL LIFE

DoFeedTri, with its strong cutting edge design, eliminated edge chipping, providing process security. As a result, more than 1.5 times tool life increase was achieved.

| Industry | Engineering |

| Component | Bracket |

| Material ISO code | |

| Work material | SUS316L |

| Machine(Spindletype) | Vertical Machining Center Large(#50, HSK100) |

| Tool family | Milling |

| Toolcategory | Profiling |

| Product name | DoFeedTri |

| TSR No. | 1682M |

IMPROVED TOOL LIFE

Welding edge was an issue with the competitor’s inserts. The customer also needed to improve tool life.

DoPent AH3225 grade eliminated welding edge and edge chipping, providing 2 times increase in tool life.

| Industry | Heavy |

| Component | Case |

| Material ISO code | |

| Work material | SC450 |

| Machine (spindle type) | Horizontal Machining Center Large (#50, HSK100) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoPent |

| TSR No. | 1325M |