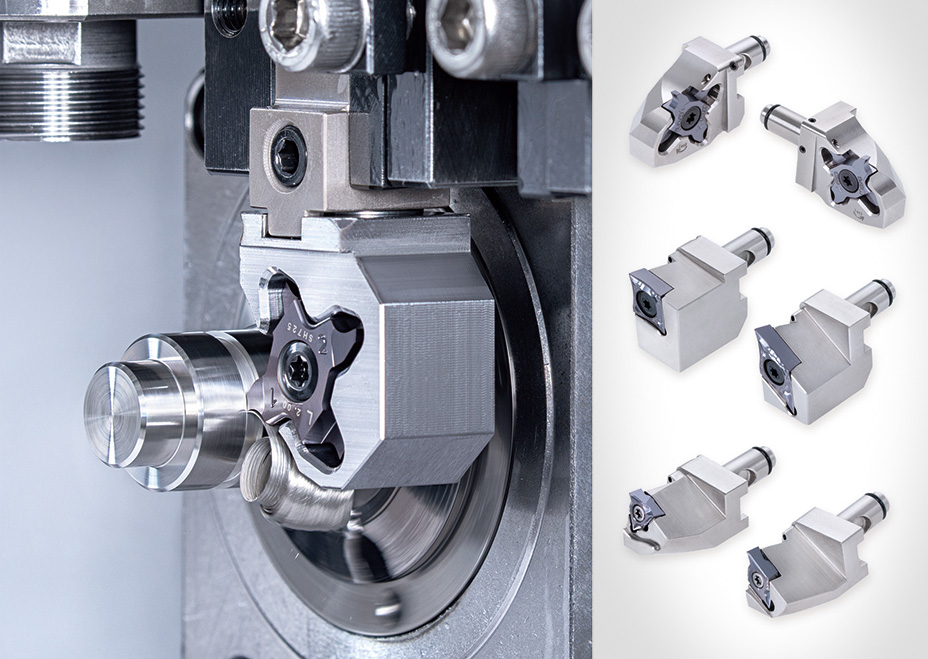

Iwaki, September 2021 — Tungaloy has expanded its ModuMini-Turn exchangeable-head modular turning tool system for Swiss machines. New cutting heads are now available for turning, grooving, and threading on Swiss machines with the feed along the Y axis, which can permanently eliminate chips associated machining challenges.

The new ModuMini-Turn cutting heads uses the Y axis feed, instead of conventional X axis motions, to machine small parts more effectively, while eliminating chip bird-nesting.

In a standard CNC Swiss machine configuration, the X axis moves the turning tool straight down onto the top of the barstock. During the operation, the chips flow over the barstock periphery and down to the basin. This traditional approach often results in chip entanglements, known as bird-nests, on the workpiece or chip clogging between the tool and workpiece creating poor part quality and scrap piles.

The new ModuMini-Turn cutting heads enter the cut sideways, in the Y axis direction, into the barstock. This new approach allows the insert to be set with the chipbreaker on the insert rake facing downward, directing the chips, aided also by gravity, downward and away from the cutting point, helping to prevent bird-nesting and ensure quality surface finishes.

In addition, ModuMini-Turn’s downfacing insert arrangement allows the brunt of the cutting force to be absorbed in the longitudinal direction, in which the tool is the strongest, enabling higher feed rates, secured process, and better part quality.

The new ModuMini-Turn cutting heads come in a smaller and more compact head design, compared with competitors’ similar tools, basically allowing another Y axis cutting tool to be located side by side on the same gang tool slide. Barstock size can vary depending on the tool’s position on the slide as well as the difference in overhang from a conventional X axis tool

The ModuMini-Turn system

ModuMini-Turn is an exchangeable-head modular turning tool system designed specifically for the use on Swiss machines, featuring unique head-shank coupling that enables reliable tool holding and secure insert edge position for good repeatability and accuracy. This high precision interface boasts extremely close cutting point repeatability of within a 5 µm range for the x and z axis when the inserts of the same sizes and shapes are swapped on the same cutting head, providing significantly reduced tool setup time and machine downtime. The holders are also available with through-coolant capability that can provide effective chip breaking solution when machining long-chipping difficult-to-cut materials.

Product information

No. 541S1-G (Metric)