Iwaki, Japan – December, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungThread series with new threading inserts featuring breakers in grade AH8015, offering superior chip control, wear resistance, and stable thread accuracy for enhanced productivity.

Challenges and Trends

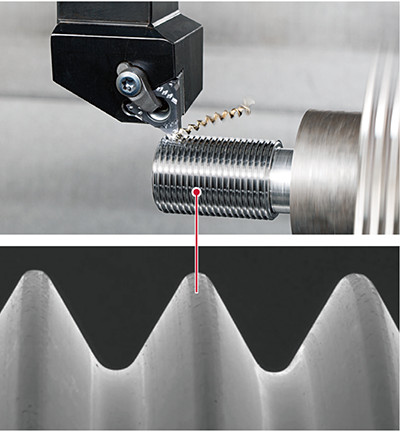

In threading applications for aircraft, general machinery, and automotive components, high precision and stable productivity are always required. However, in the threading process, chip control is often difficult, leading to issues such as chip entanglement that can cause machine downtime or machining defects. In addition, variations in workpiece materials and cutting conditions can make tool life unstable, resulting in difficulties in maintaining thread accuracy.

Given these challenges, there is a growing demand for new inserts that can achieve both stable chip evacuation and long tool life while ensuring consistent thread accuracy.

Product Overview

TungThread is a high-performance threading tool series provided by Tungaloy. It is compatible with a wide range of machines, from general NC lathes to automatic and multi-tasking lathes, enabling high-precision machining of various thread types such as ISO and API threads. Featuring excellent wear resistance and long tool life, it achieves both high productivity and superior machining quality.

Benefits and Features

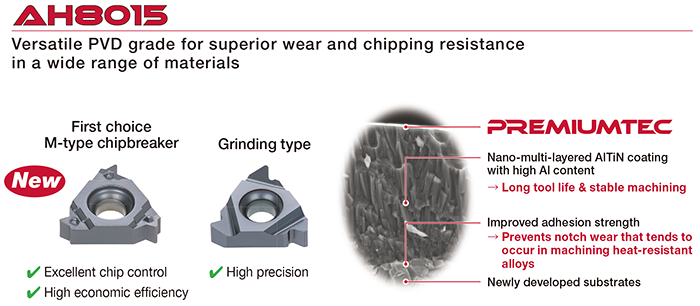

Feature 1: AH8015 grade delivers excellent wear resistance and long tool life

– The high-aluminum multilayer coating provides outstanding wear resistance and enables stable machining over extended periods.

– Significantly improved coating adhesion minimizes chipping and fracture.

– Offers consistent threading performance across a wide range of materials, from steel and stainless steel to cast iron.

Feature 2: Superior chip control with breaker-equipped inserts

– Optimized breaker geometry enhances chip breaking performance.

– Prevents chip wrapping and tangling during machining, ensuring stable automated operation.

– Improved chip evacuation contributes to both superior surface finish and extended tool life.

Feature 3: Flexible system design adaptable to diverse machining conditions

– TungThread’s extensive holder lineup accommodates various thread profiles and machining environments.

– Standardized insert design allows for easy replacement and setup.

– Enables high-efficiency, high-precision threading across a wide range of applications.

Cutting Performance

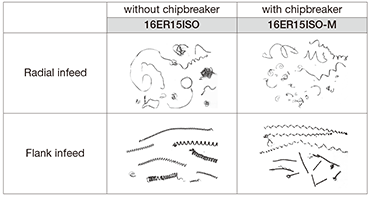

CHIP CONTROL: M-type chipbreaker

| Workpiece material | S45C / C45 |

| Screw Size | M24 X 1.5 |

| Cutting speed | Vc = 180 m/min |

| Machining | External threading |

Improved chip control

Excellent surface quality