Iwaki, Japan – December, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its T6200 and AH6200 series, introducing the new CVD grade T6225 with 51 ISO turning inserts optimized for stainless steel applications under a wide range of cutting conditions.

Challenges and Trends

In the turning of stainless steel, cutting tools are required to have high wear resistance and stable tool life. This is especially important in fields such as general machining and the automotive industry, where components like shafts, rods, pistons, and valves demand high durability, making efficient and stable machining essential. In some cases, the conventional grade AH6225 has shown inferior wear resistance compared to competitor products, leading to strong market demand for a higher-performance grade. In response to these challenges and market conditions, the development and expanded application of the new CVD grade T6225 are highly anticipated.

Product Overview

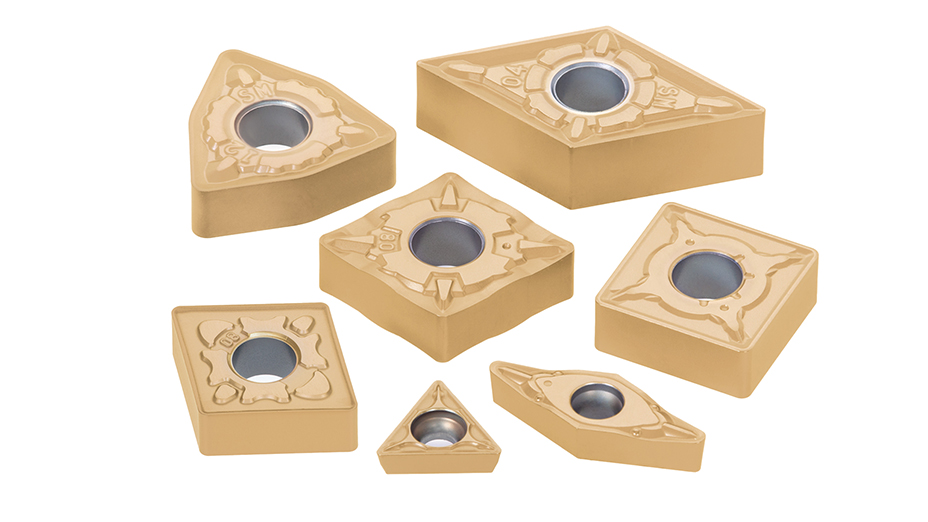

The T6200 & AH6200 series are high-performance inserts specifically designed for turning stainless steel. They offer excellent wear resistance and thermal stability, making them suitable for a wide range of applications from continuous to interrupted cutting. With long tool life and high reliability, they contribute to improved productivity.

Benefits and Features

Feature 1: High Versatility with Excellent Wear and Fracture Resistance

– The new grade T6225 offers a well-balanced combination of wear resistance and fracture toughness, making it suitable for a wide range of machining conditions.

– Optimized for the M25 application range, it delivers intermediate performance between T6215 (high wear resistance) and AH6225 (high fracture resistance).

– Capable of covering a broad spectrum of stainless steel machining applications from M20 to M30, it increases flexibility in tool selection.

Feature 2: Enhanced Reliability with Newly Developed High-Adhesion Al₂O₃ Coating

– Improved adhesion of the Al₂O₃ coating significantly reduces the risk of chipping and coating delamination.

– The coating thickness has been increased by 1.3 times compared to conventional products, extending tool life.

– The high-hardness outer layer provides excellent resistance to flank wear, ensuring stable machining quality.

Feature 3: High-Performance Series for Stainless Steel Machining

– The T6200 series (T6215, T6225) and AH6200 series (AH6225, AH6235) consist of four grades that allow optimal selection based on the application and cutting conditions.

– Expansion to 51 item of ISO-standardized items enables coverage of a wide range of machining needs.

– The entire series delivers high machining stability and long tool life, contributing to overall cost reduction.

Cutting Performance

| Insert | CNMG1204** |

| Cutting speed | Vc = 150 m/min |

| feed | f = 0.3 mm/rev |

| Depth of cut | ap = 2 mm |

| Machining | Continuous cutting |

| Coolant | Wet |

T6225 demonstrated superior resistance to wear and plastic deformation during machining of austenitic stainless steel.