Iwaki, Japan – November, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DrillMeister series with new DMM drill head sizes ranging from 17 mm to 19.9 mm, optimized for stainless steel and other difficult-to-machine materials. The new heads offer excellent chip evacuation and wear resistance, and can be mounted on existing DrillMeister bodies without modification.

Challenges and Trends

In fields such as generator components, heat exchangers, fluid valves, and fittings, corrosion-resistant stainless steels and difficult-to-machine materials are commonly used. However, these materials are challenging to process, often leading to shorter tool life, increased tooling costs, and reduced productivity. In particular, chip evacuation is difficult, frequently requiring step drilling to remove chips effectively, which impacts machining efficiency and tool stability. As a result, there is a growing demand for high-performance drill heads.

Product Overview

AddMeisterDrill / DrillMeister is a high-performance exchangeable head drill system. A variety of drill heads can be mounted on a single body, significantly improving machining accuracy, tool life, and operational efficiency. With a diameter range of 4 to 25.9 mm, it is ideal for a wide range of drilling applications.

Benefits and Features

Feature 1: Excellent Chip Evacuation Performance and Stable Machining

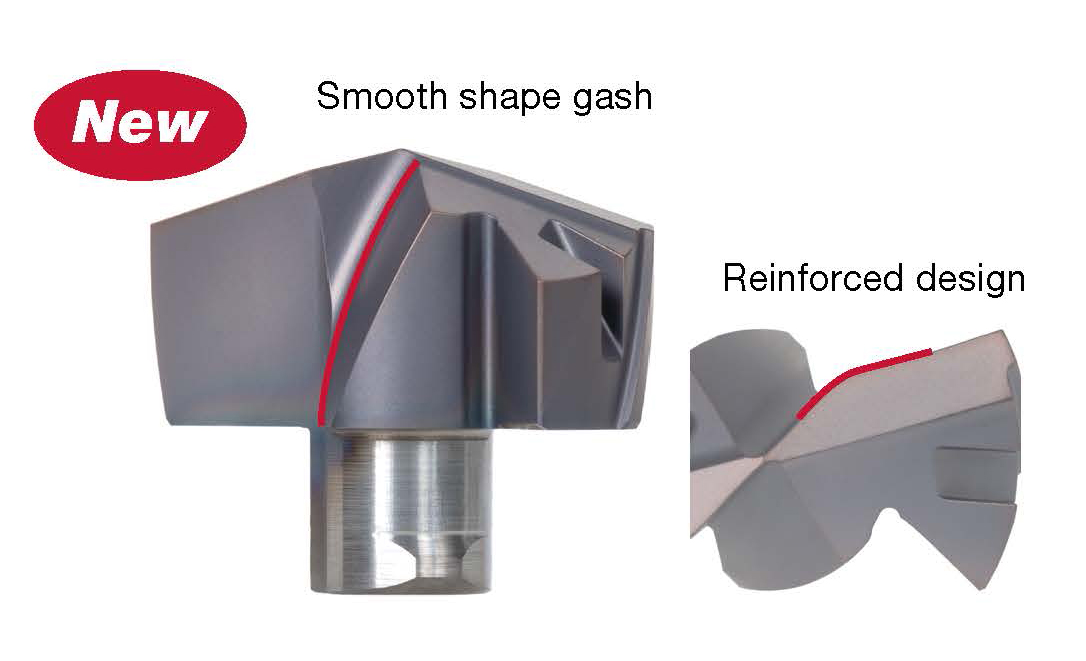

– The unique gash geometry efficiently evacuates chips even when machining stainless steel or difficult-to-cut materials that tend to produce long chips.

– A wide thinning pocket reduces cutting edge load during chip formation, minimizing vibration and cutting resistance during machining.

– Enables stable drilling without the need for step drilling, contributing to process simplification and shorter machining time.

Feature 2: High Wear Resistance and Long Tool Life

– Utilizes the drill-specific grade AH9130, which delivers excellent wear resistance under high-temperature and high-load conditions typical of difficult-to-machine materials.

– Suppresses edge wear to reduce tool replacement frequency, helping to lower total costs.

– Extended tool life enhances reliability in continuous machining and automated production lines.

Feature 3: Expanded Lineup for Greater Application Flexibility

– Newly added drill head diameters ranging from 17 mm to 19.9 mm accommodate a wider range of machining needs.

– Compatible with existing DrillMeister bodies without modification, allowing for optimized tool inventory and reduced setup time.

– Flexible diameter selection enables a balance between machining accuracy and productivity.

Success Stories

IMPROVE TOOL LIFE & PRODUCTIVITY

This case involves drilling for tube sheet, a component used in heat exchangers.

Because the material was a high-hardness stainless steel, short tool life had been a major issue.

We proposed the newly developed DMM head, designed specifically for stainless-steel applications.

After making minor adjustments to the cutting conditions, machining was performed at a 20% higher productivity than the previous setup.

As a result, the new tool achieved 1.8 times the number of holes compared with the existed tool.

| Industry | Heat Exchanger |

| Component | Tube sheet |

| Material ISO code | |

| Work material | Duplex stainless steel |

| Material hardness | 30 HRC |

| Machine(spindle type) | Vertical Machining Center Large (#50, HSK100) |

| Tool family | Holemaking |

| Tool category | Drilling Through Hole |

| Product name | DrillMeister |

| TSR No. | 5436H |