Combines Pressed-in Chipbreaker and SH7025 Grade for Improved Chip Control and Surface Quality

Iwaki, Japan, June, 2024 – Tungaloy Corporation (President: Satoshi Kinoshita, Headquarters: Iwaki, Fukushima) announces the addition of back turning inserts to its DuoJustCut series, primarily used in automatic lathes for grooving and parting-off operations.

Overview;

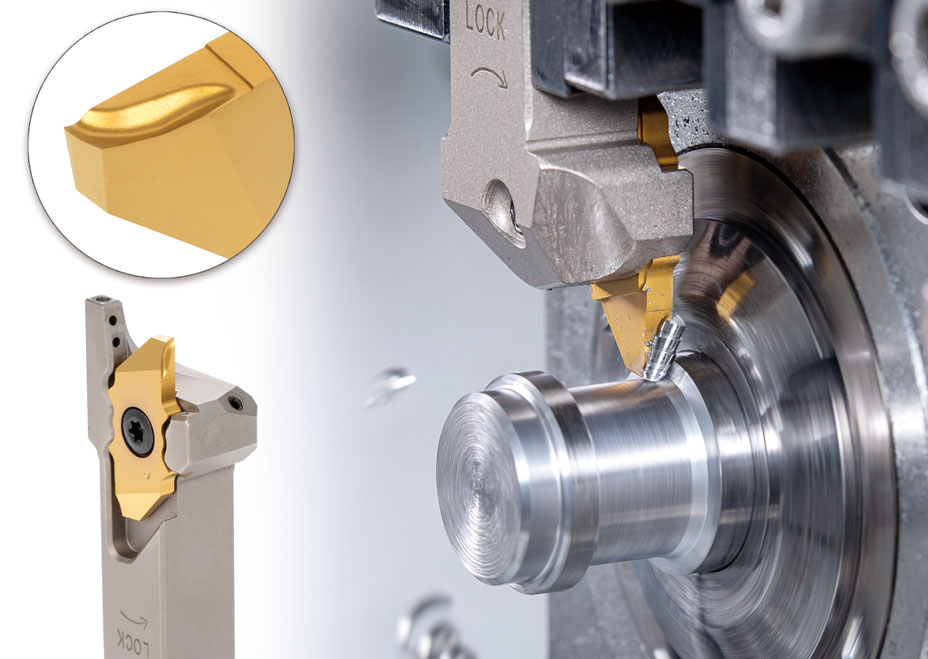

DuoJustCut is a versatile tool for parting-off, grooving, and threading applications, featuring unique 2-corner inserts. The series ensures high insert clamping rigidity due to its unique clamping mechanism, allowing full use of both corners without affecting the opposite cutting edge even if one edge is damaged.

The new back turning insert, designated JXBM12, features a newly designed cutting edge and a pressed-in chipbreaker that ensures excellent chip control during grooving and back turning operations. The insert also includes a wiper edge on the front cutting edge, delivering superior surface finish.

The insert is made from the newly developed SH7025 PVD grade, designed for small part machining. SH7025 combines a tough carbide substrate with a columnar TiCN layer and a multilayered TiAlN coating, reducing micro chipping and wear progression. This results in excellent surface finish and stable long tool life. Additionally, the gold-colored SH7025 grade makes it easy to identify used corners and damage, even in low-light environments.

The addition of the JXBM12 back turning insert to the DuoJustCut series enhances productivity and reduces machining costs for small part manufacturers across various industries.

Product information

No. 504S4-G (Metric)

DuoJust-Cut