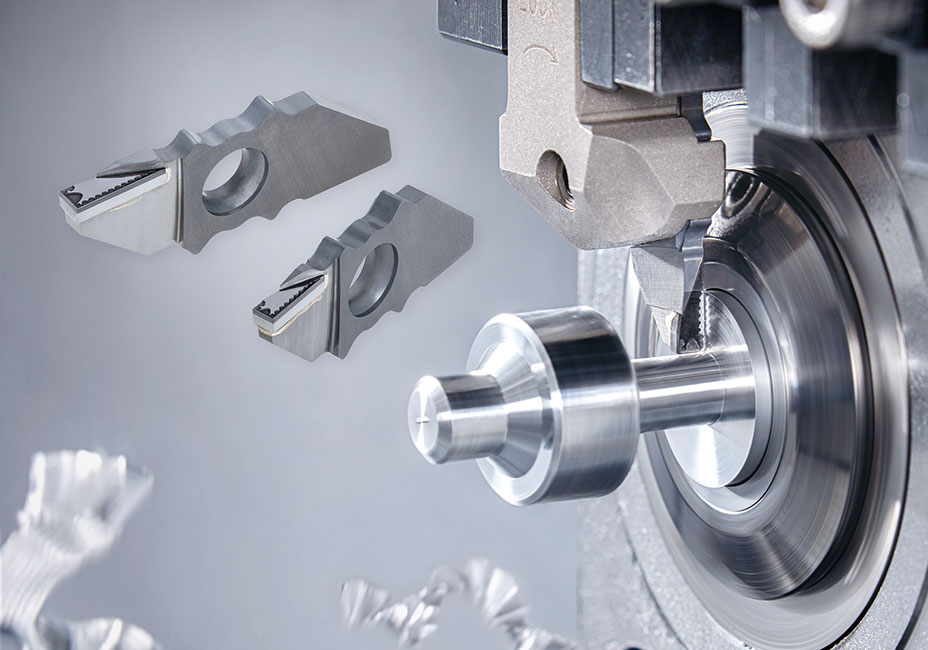

Iwaki, November 2021 — Tungaloy has introduced PCD-tipped grooving inserts with 3D chipbreaker for its DuoJust-Cut line for increased productivity in Swiss machining of complicated aluminum parts.

Complicated cylindrical aluminum parts such as sliding spools for directional control valves are widely used in the automotive hydraulic system. The length-to-diameter ratio of these parts lends itself quite well to Swiss-style lathes. To shorten cycle time, shops typically use a single continuous pass to contour a complicated profile using a grooving tool with side turning capability. While they usually choose uncoated carbide inserts because of their wide availability of various chipbreaker styles for desired chip breaking effect, the new DuoJust-Cut insert features a PCD-tipped cutting edge with 3D chipbreaker on its rake. This not only ensures effective chip breaking when contouring complicated cylindrical parts with varying cutting depths and feed directions, but also provides much longer tool life and superior surface finish than carbide inserts. Capable of up to 7 mm or .276″ depth of cut, the PCD insert, with its ingenious chipbreaker design, ensures effective chip control regardless of the cutting depths the insert is used at.

The insert is offered in DX110, a PCD grade consisting of submicron grained polycrystalline diamond powders that provides mirror-like surface finish.

Three total inserts: JXDX12R20F DX110, JXDX12R25F DX110, and JXDX16R25F DX110 are introduced. They fit all existing DuoJust-Cut toolholders. With its proven insert clamping rigidity, the tool ensures stability and reliability at aggressive depths of cut.

Product information

No. 504S2-G (Metric)