Iwaki, Japan – January, 2026 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungMeister series with the addition of the R0.2 corner radius square head, delivering solid end mill–level precision and enhanced flexibility for high-efficiency machining of precision parts and molds.

Challenges and Trends

In the machining of precision components and molds, there is a growing number of cases where very small corner radii, such as corner R0.3 or less, are specified on drawings. Conventional TungMeister square heads, with a minimum radius of R0.5, cannot accommodate these requirements, forcing users to rely on solid end mills instead. However, solid tools present challenges in terms of machining efficiency and cost, leading to increasing demand for high-efficiency, low-cost machining solutions using exchangeable-head tools. The market has clearly defined a need for exchangeable heads capable of handling smaller corner radii, and there is a strong call for new solutions that achieve both precision and productivity.

Product Overview

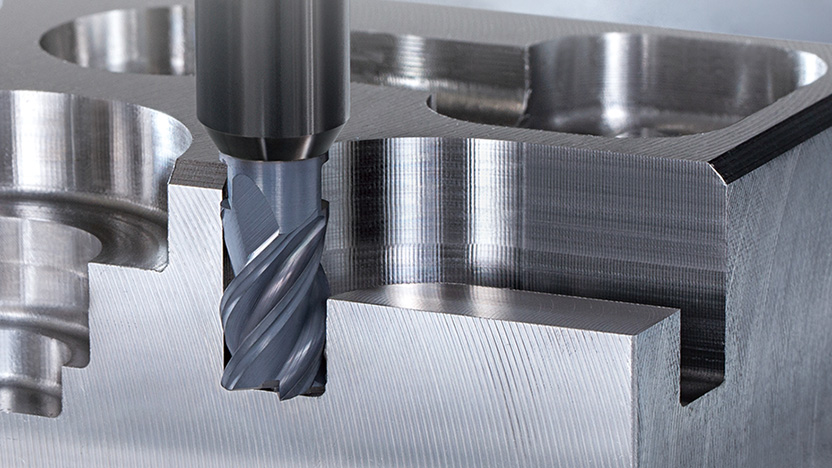

TungMeister is Tungaloy’s high-efficiency exchangeable-head end mill series.

With over 45 head geometries and a wide variety of shank materials, it meets a broad range of machining requirements.

The simple head replacement reduces setup time while achieving high precision and productivity.

Benefits and Features

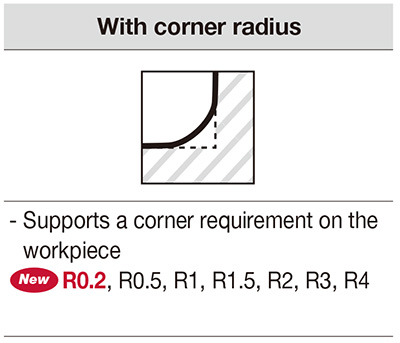

Feature 1: Support for High-Precision Machining with the Addition of Corner Radius R0.2

– The new R0.2 corner radius enables machining of parts with drawing specifications requiring corner radii of R0.3 or smaller.

– Achieves small-radius corner machining with an exchangeable-head tool, making it a viable alternative to solid end mills.

– Ideal for machining applications that demand fine corner details, such as high-precision components and molds.

Feature 2: Reduced Setup Time with Exchangeable-Head System

– The separable structure between the cutting edge and the shank allows for quick tool replacement.

– Minimizes the need for readjusting tool overhang length, significantly reducing machine downtime.

– Ensures stable repeatability and maintains high machining accuracy even after head replacement.

Feature 3: High-Efficiency Machining Enabled by a High-Rigidity Shank

– Increased shank diameter enhances overall tool rigidity.

– Overhang length can be freely adjusted, allowing easy optimization of machining conditions.

– Suppresses chatter and ensures stable machining under high-feed and deep-cutting conditions.