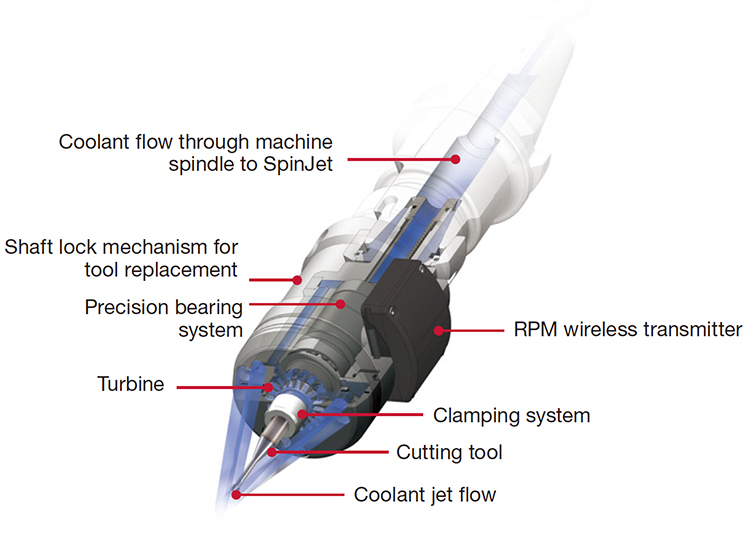

Coolant-driven high speed compact spindle

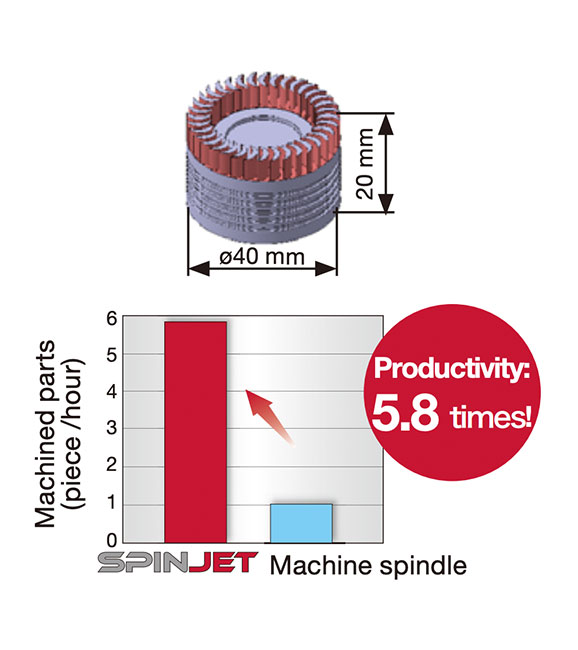

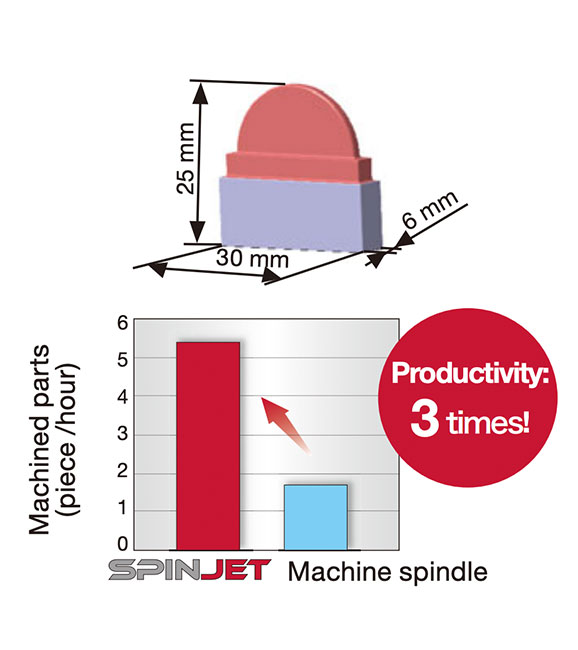

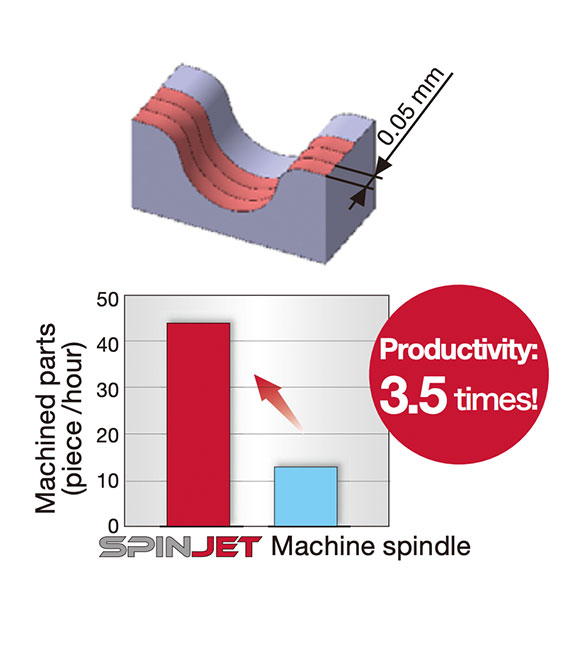

Productivity quadruples due to spindles that rotate at high speed with coolant pressure

Features

1. Coolant-driven HSM spindle for high productivity with small diameter tools on limited RPM machines

• SpinJet utilizes the machine tool’s existing coolant supply, driven by a high pressure pump as an energy source to rotate a turbine at high speeds.

• Strong coolant jet flow provide extended tool life and machining stability.

2. Energy saving

• Tools rotate only with coolant pressure, and the machine spindle is idle while SpinJet is in operation.

Note: The main machine spindle should be stationary while the SpinJet spindle is mounted on the machine.

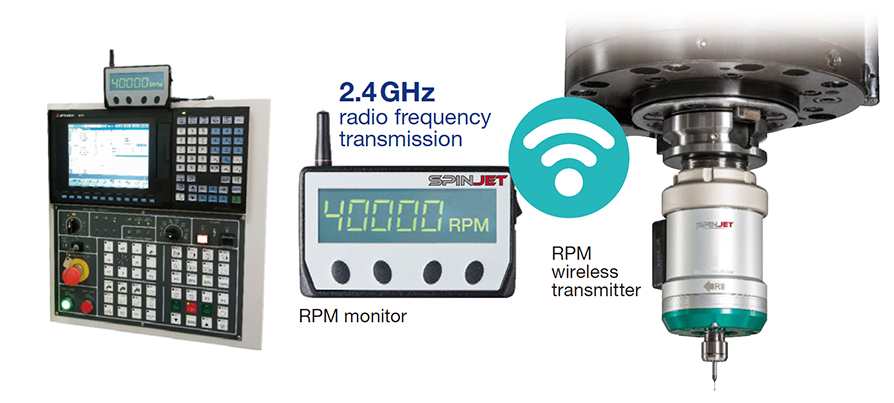

3. Wireless RPM monitoring system

• SpinJet is equipped with an online speed display system, monitoring the actual cutting tool rotation speed during machining.

Holders & Accessories

Practical examples

Example #1

General Engineering

| Part: | Machine parts |

| Material: | SUS303 / X10CrNiS18-9 (25HRC) |

| Holder: | TJSGJETST20 |

| Endmill: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| Grade: | AH750 |

| Cutting conditions: | Vc = 120 (m/min) n = 45,600 (RPM) fz = 0.016 (mm/t) ap = 0.01 (mm) ae = 1 (mm) Application: Grooving Coolant: Wet Machine: Vertical M/C, BT30 |

Example #2

Die and Mold Industry

| Part: | Electrode |

| Material: | C1100 |

| Holder: | TJSGJETST20 |

| Endmill: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| Grade: | AH750 |

| Cutting conditions: | Vc = 95 (m/min) n = 40,000 (RPM) fz = 0.025 (mm/t) ap = 0.04 (mm) ae = 0.04 (mm) Application: Profiling Coolant: Wet Machine: Vertical M/C, BT30 |

Example #3

Medical Industry

| Part: | Medical equipment |

| Material: | Titanium alloys |

| Holder: | TJSGJETER32 |

| Endmill: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| Grade: | AH750 |

| Cutting conditions: | Vc = 80 (m/min) n = 35,000 (RPM) fz = 0.03 (mm/t) ap = 0.03 (mm) ae = 0.05 (mm) Application: Profiling Coolant: Wet Machine: Vertical M/C, BT30 |

Standard cutting conditions

TJS M00

| ISO | Workpiece material | Tool | Application | Tool diameter DC (mm) |

Coolant pressure (MPa) |

Spindle speed n (min-1) |

Width of cut ae (mm) |

Depth of cut ap (mm) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|---|---|

|

Alloy steel 35 HRC |

Drill | Drilling | 0.5 | 1.5 | 18,000 | – | – | 0.007 |

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| Ball type endmill |

Profiling | 1 | 1.5 | 18,000 | – | 0.05 | 0.003 | ||

| 2 | 23,000 | – | 0.05 | 0.003 | |||||

| 3 | 31,000 | – | 0.05 | 0.003 | |||||

| 4 | 40,000 | – | 0.05 | 0.003 | |||||

| 2 | 1.5 | 18,000 | – | 0.08 | 0.004 | ||||

| 2 | 23,000 | – | 0.08 | 0.004 | |||||

| 3 | 31,000 | – | 0.08 | 0.004 | |||||

| 4 | 40,000 | – | 0.08 | 0.004 | |||||

| 3 | 1.5 | 18,000 | – | 0.1 | 0.006 | ||||

| 2 | 23,000 | – | 0.1 | 0.006 | |||||

| 3 | 31,000 | – | 0.1 | 0.006 | |||||

| 4 | 40,000 | – | 0.1 | 0.006 | |||||

| Endmill | Slotting | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.006 | ||

| 2 | 23,000 | 1 | 0.1 | 0.006 | |||||

| 3 | 31,000 | 1 | 0.1 | 0.006 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.006 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.12 | 0.01 | ||||

| 2 | 23,000 | 2 | 0.12 | 0.01 | |||||

| 3 | 31,000 | 2 | 0.14 | 0.01 | |||||

| 4 | 40,000 | 2 | 0.14 | 0.01 | |||||

| 3 | 1.5 | 18,000 | 3 | 0.12 | 0.01 | ||||

| 2 | 23,000 | 3 | 0.12 | 0.01 | |||||

| 3 | 31,000 | 3 | 0.12 | 0.01 | |||||

| 4 | 40,000 | 3 | 0.15 | 0.01 | |||||

| Shouldering | 2 | 1.5 | 18,000 | 0.5 | 0.5 | 0.002 | |||

| 2 | 23,000 | 0.5 | 0.5 | 0.014 | |||||

| 3 | 31,000 | 0.5 | 0.5 | 0.017 | |||||

| 4 | 40,000 | 0.5 | 0.5 | 0.018 | |||||

|

Stainless steel 180 – 250 HB |

Drill | Drilling | 0.5 | 1.5 | 18,000 | – | – | 0.015 |

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| Endmill | Slotting | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.015 | ||

| 2 | 23,000 | 1 | 0.1 | 0.015 | |||||

| 3 | 31,000 | 1 | 0.15 | 0.015 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.015 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.15 | 0.015 | ||||

| 2 | 23,000 | 2 | 0.15 | 0.015 | |||||

| 3 | 31,000 | 2 | 0.15 | 0.015 | |||||

| 4 | 40,000 | 2 | 0.2 | 0.015 | |||||

| Shouldering | 2 | 1.5 | 18,000 | 0.35 | 0.15 | 0.02 | |||

| 2 | 23,000 | 0.35 | 0.15 | 0.02 | |||||

| 3 | 31,000 | 0.4 | 0.15 | 0.02 | |||||

| 4 | 40,000 | 0.5 | 0.18 | 0.025 | |||||

|

Aluminium alloy 80 – 160 HB |

Drill | Drilling | 0.5 | 1.5 | 18,000 | – | – | 0.01 |

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.017 | |||||

| 4 | 40,000 | – | – | 0.018 | |||||

| Ball type endmill |

Profiling | 1 | 1.5 | 18,000 | – | 0.05 | 0.003 | ||

| 2 | 23,000 | – | 0.05 | 0.003 | |||||

| 3 | 31,000 | – | 0.05 | 0.003 | |||||

| 4 | 40,000 | – | 0.13 | 0.003 | |||||

| 2 | 1.5 | 18,000 | – | 0.08 | 0.004 | ||||

| 2 | 23,000 | – | 0.08 | 0.004 | |||||

| 3 | 31,000 | – | 0.08 | 0.004 | |||||

| 4 | 40,000 | – | 0.15 | 0.004 | |||||

| 3 | 1.5 | 18,000 | – | 0.08 | 0.006 | ||||

| 2 | 23,000 | – | 0.09 | 0.006 | |||||

| 3 | 31,000 | – | 0.09 | 0.006 | |||||

| 4 | 40,000 | – | 0.15 | 0.006 | |||||

| Endmill | Slotting | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.025 | ||

| 2 | 23,000 | 1 | 0.1 | 0.025 | |||||

| 3 | 31,000 | 1 | 0.15 | 0.025 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.025 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.2 | 0.025 | ||||

| 2 | 23,000 | 2 | 0.2 | 0.025 | |||||

| 3 | 31,000 | 2 | 0.2 | 0.025 | |||||

| 4 | 40,000 | 2 | 0.2 | 0.025 | |||||

| Shouldering | 2 | 1.5 | 18,000 | 0.5 | 0.25 | 0.02 | |||

| 2 | 23,000 | 0.5 | 0.25 | 0.02 | |||||

| 3 | 31,000 | 0.5 | 0.5 | 0.02 | |||||

| 4 | 40,000 | 0.5 | 0.5 | 0.025 |

TJS M90

| ISO | Workpiece material | Tool | Application | Tool diameter DC (mm) |

Coolant pressure (MPa) |

Spindle speed n (min-1) |

Width of cut ae (mm) |

Depth of cut ap (mm) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|---|---|---|---|---|

|

Pre-hardened steel 35 HRC |

Drill | Drilling | 0.5 | 2 | 35,000 | – | – | 0.01 |

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 1 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 2 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| Ball type endmill |

Profiling | 1 | 2 | 35,000 | – | 0.05 | 0.003 | ||

| 3 | 44,000 | – | 0.05 | 0.003 | |||||

| 4 | 53,000 | – | 0.05 | 0.003 | |||||

| 2 | 2 | 35,000 | – | 0.08 | 0.004 | ||||

| 3 | 44,000 | – | 0.08 | 0.004 | |||||

| 4 | 53,000 | – | 0.08 | 0.004 | |||||

| 3 | 2 | 35,000 | – | 0.1 | 0.006 | ||||

| 3 | 44,000 | – | 0.1 | 0.006 | |||||

| 4 | 53,000 | – | 0.1 | 0.006 | |||||

| Endmill | Slotting | 0.5 | 2 | 35,000 | 0.5 | 0.05 | 0.006 | ||

| 3 | 44,000 | 0.5 | 0.05 | 0.006 | |||||

| 4 | 53,000 | 0.5 | 0.05 | 0.006 | |||||

| 1 | 2 | 35,000 | 1 | 0.1 | 0.006 | ||||

| 3 | 44,000 | 1 | 0.1 | 0.006 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.006 | |||||

| 2 | 2 | 35,000 | 2 | 0.12 | 0.01 | ||||

| 3 | 44,000 | 2 | 0.14 | 0.01 | |||||

| 4 | 53,000 | 2 | 0.14 | 0.01 | |||||

| 3 | 2 | 35,000 | 3 | 0.12 | 0.01 | ||||

| 3 | 44,000 | 3 | 0.12 | 0.01 | |||||

| 4 | 53,000 | 3 | 0.15 | 0.01 | |||||

| Shouldering | 2 | 2 | 35,000 | 0.5 | 0.5 | 0.001 | |||

| 3 | 44,000 | 0.5 | 0.5 | 0.017 | |||||

| 4 | 53,000 | 0.5 | 0.5 | 0.018 | |||||

|

Stainless steel SUS316 35 HRC |

Drill | Drilling | 0.5 | 2 | 35,000 | – | – | 0.015 |

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| 1 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| 2 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| Endmill | Slotting | 1 | 2 | 35,000 | 1 | 0.1 | 0.015 | ||

| 3 | 44,000 | 1 | 0.15 | 0.015 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.015 | |||||

| 2 | 2 | 35,000 | 2 | 0.15 | 0.015 | ||||

| 3 | 44,000 | 2 | 0.15 | 0.015 | |||||

| 4 | 53,000 | 2 | 0.2 | 0.015 | |||||

| Shouldering | 2 | 2 | 35,000 | 0.35 | 0.15 | 0.02 | |||

| 3 | 44,000 | 0.4 | 0.15 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.18 | 0.025 | |||||

|

Aluminium alloy ADC12 28 HRC |

Drill | Drilling | 0.5 | 2 | 35,000 | – | – | 0.01 |

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 1 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 2 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.017 | |||||

| 4 | 53,000 | – | – | 0.018 | |||||

| Ball type endmill |

Profiling | 1 | 2 | 35,000 | – | 0.05 | 0.003 | ||

| 3 | 44,000 | – | 0.05 | 0.003 | |||||

| 4 | 53,000 | – | 0.13 | 0.003 | |||||

| 2 | 2 | 35,000 | – | 0.08 | 0.004 | ||||

| 3 | 44,000 | – | 0.08 | 0.004 | |||||

| 4 | 53,000 | – | 0.15 | 0.004 | |||||

| 3 | 2 | 35,000 | – | 0.08 | 0.006 | ||||

| 3 | 44,000 | – | 0.09 | 0.006 | |||||

| 4 | 53,000 | – | 0.15 | 0.006 | |||||

| Endmill | Slotting | 0.5 | 2 | 35,000 | 0.5 | 0.1 | 0.02 | ||

| 3 | 44,000 | 0.5 | 0.12 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.15 | 0.02 | |||||

| 1 | 2 | 35,000 | 1 | 0.1 | 0.025 | ||||

| 3 | 44,000 | 1 | 0.15 | 0.025 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.025 | |||||

| 2 | 2 | 35,000 | 2 | 0.2 | 0.025 | ||||

| 3 | 44,000 | 2 | 0.2 | 0.025 | |||||

| 4 | 53,000 | 2 | 0.2 | 0.025 | |||||

| Shouldering | 2 | 2 | 35,000 | 0.5 | 0.25 | 0.02 | |||

| 3 | 44,000 | 0.5 | 0.5 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.5 | 0.025 | |||||

|

Tool steel SKD61 58 HRC |

Ball type endmill |

Profiling | 1 | 2 | 35,000 | – | 0.05 | 0.005 |

| 3 | 44,000 | – | 0.05 | 0.005 | |||||

| 4 | 53,000 | – | 0.05 | 0.005 | |||||

| 2 | 2 | 35,000 | – | 0.07 | 0.006 | ||||

| 3 | 44,000 | – | 0.08 | 0.006 | |||||

| 4 | 53,000 | – | 0.08 | 0.006 | |||||

| 3 | 2 | 35,000 | – | 0.08 | 0.006 | ||||

| 3 | 44,000 | – | 0.1 | 0.006 | |||||

| 4 | 53,000 | – | 0.1 | 0.006 |

For more information about this product, visit our online e-catalog or download the product report:

Contact Tungaloy relate to SpinJet

If you need some assistances from Tungaloy, please contact us in the follwoing contact form