SiAlON ceramic inserts for super alloy turning

Highly reliable SiAlON inserts for high temperature alloy turning

Applications & Features

Applications

Features

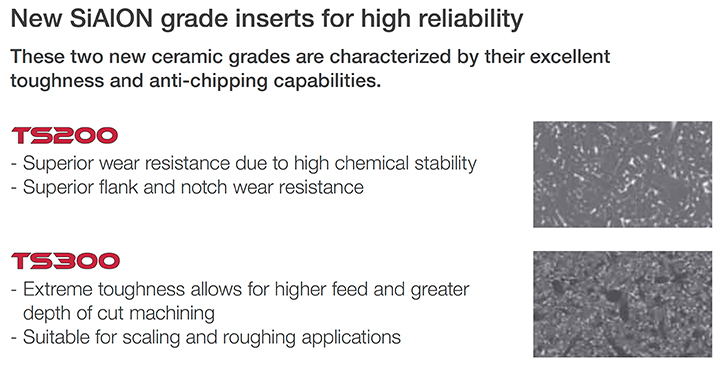

1. New SiAlON grade inserts for high reliability

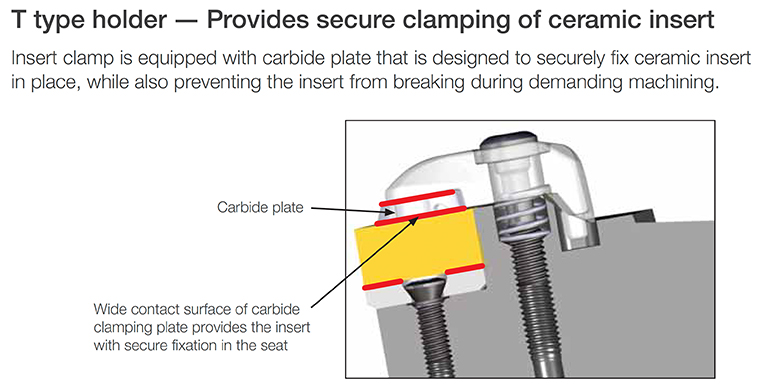

2. T type holder – Provides secure clamping of ceramic insert

Gradi

TS200

![]()

- Superior wear resistance due to high chemical stability

- Superior flank and notch wear resistance

TS300

![]()

- Extreme toughness allows for higher feed and greater depth of cut machining

- Suitable for scaling and roughing applications

Toolholders

Practical examples

Example #1

Aerospace Industry

| Part: | Aircraft part |

| Toolholder: | CRGNL2525M1207 |

| Material: | INCONEL718 |

| Insert: | RNGN120700-E |

| Grade: | TS200 |

| Cutting conditions: | Vc =TS200: 280 (m/min), Competitor: 210 (m/min) f = 0.2 (mm/rev) ap = 1.5 (mm) Application: External turning Coolant: Wet |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report: