Various type of tools for thread milling

Highly suitable for threading of heat-resistant alloys or hardened steels

Also, applicable for large sized threading with low cutting forces

Applications & Features

Applications

Features

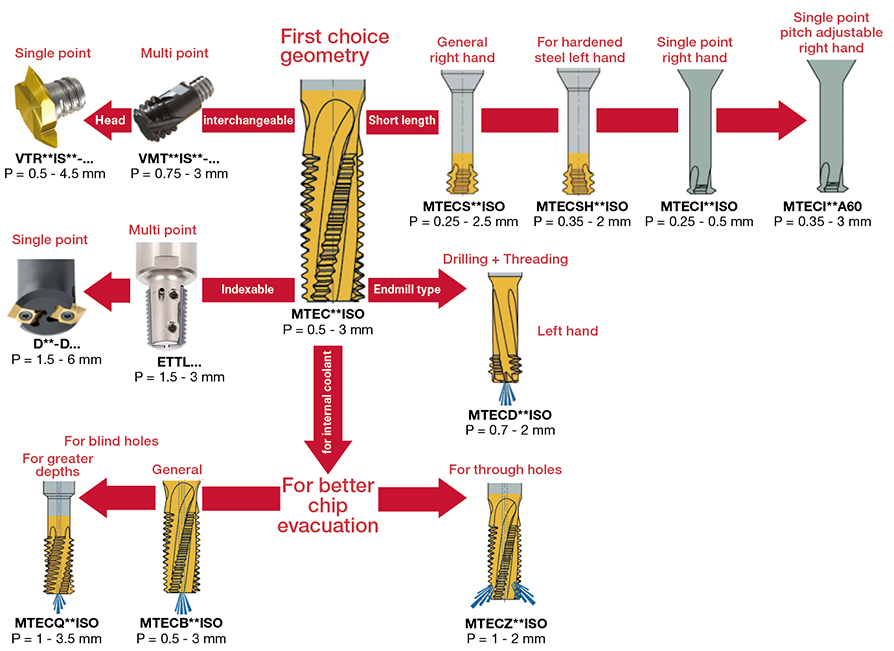

Tool selection guide for internal ISO metric threads

Inserts, Heads, Solid Carbide Endmills & Grades

Inserts, Heads, Solid Carbide Endmills

Solid Carbide Endmills

SolidThread

- Pitch 0.25 mm – 3.5 mm, Tool diameter 0.72mm

- Machining small diameter threads, such as M1x0.25 and 0-80UNF

Heads

TungMeister Heads for threading (VMT / VTR)

- Pitch 0.5 mm – 4.5 mm, Tool diameter 10 mm

- Head-changeable Thread-milling tools for less down-time than a solid tapping tool

Inserts

Inserts for Indexable Thread Milling

- Pitch 1.5 mm – 6.0 mm, Tool diameter 17 mm

- Able to incorporate multiple inserts for various threading diameters and pitches

Grades

AH725

![]()

![]()

![]()

![]()

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

GH330

![]()

![]()

![]()

- High resistance to wear and fracture

- Suitable for continuous to medium interrupted cutting

Cutter bodies

Shank Type

Indexable Thread Milling (ø17- ø80 mm)

Cylindrical type holders for counter boring

Esempi di lavorazione

Standard cutting conditions

SolidThread

| ISO | Material | Condition | Tensile strength [N/mm2] |

Hardness HB |

Cutting speed (m/min) |

Tool dia: DC(mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed: f (mm/t) | ||||||||||||||||||

| AH725 | ø2 | ø3 | ø4 | ø6 | ø8 | ø10 | ø12 | ø14 | ø16 | ø20 | ø25 | ø30 | ||||||

|

Non-alloy steel and cast steel, free cutting stee |

< 0.25 %C | Annealed | 420 | 125 | 100 – 250 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 |

| ≧ 0.25 %C | Annealed | 650 | 190 | 80 – 210 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| < 0.55 %C | Quenched and tempered | 850 | 250 | 65 – 170 | ||||||||||||||

| ≧ 0.55 %C | Annealed | 750 | 220 | 110 – 180 | 0.02 | 0.03 | 0.03 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.15 | 0.18 | ||

| Quenched and tempered | 1000 | 300 | 95 – 160 | 0.02 | 0.03 | 0.03 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.15 | 0.18 | |||

| Low alloy steel and cast steel (less than 5% of alloying elements) |

Annealed | 600 | 200 | 90 – 160 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Quenched and tempered | 930 | 275 | 65 – 200 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| 1000 | 300 | 70 – 210 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||||

| 1200 | 350 | 95 – 160 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||||

| High alloyed steel, cast steel, and tool steel |

Annealed | 680 | 200 | 130 – 170 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Quenched and tempered | 1100 | 325 | 75 – 100 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| Stainless steel and cast steel | Ferritic/martensitic | 680 | 200 | 110 – 170 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Martensitic | 820 | 240 | 70 – 155 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

|

Stainless steel | Austenitic | 600 | 180 | 85 – 100 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |

|

Cast iron nodular (GGG) | Ferritic/martensitic | 180 | 120 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Pearlitic | 260 | 75 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||||

| Grey cast iron (GG) | Ferritic | 160 | 70 – 150 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | |||

| Pearlitic | 250 | 110 – 140 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||||

| Malleable cast iron | Ferritic | 130 | 120 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | |||

| Pearlitic | 230 | 110 – 140 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||||

|

Aluminum- wrought alloy | Not cureable | 60 | 160 – 300 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Cured | 100 | |||||||||||||||||

| Aluminum-cast, alloyed |

≦12% Si | Not cureable | 75 | 150 – 350 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Cured | 90 | |||||||||||||||||

| >12% Si | High temperature | 130 | 100 – 250 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.12 | |||

| Copper alloys | >1% Pb | Free cutting | 110 | |||||||||||||||

| Brass | 90 | |||||||||||||||||

| Electrolitic copper | 100 | |||||||||||||||||

| Non-metallic | Duroplastics, fiber plastics | 100 – 400 | 0.05 | 0.06 | 0.07 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.15 | 0.18 | 0.22 | 0.25 | ||||

| Hard rubber | ||||||||||||||||||

|

High temp. alloys | Fe based | Annealed | 200 | ||||||||||||||

| Cured | 280 | |||||||||||||||||

| Ni or Co based | Annealed | 250 | 20 – 80 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | |||

| Cured | 350 | |||||||||||||||||

| Cast | 320 | |||||||||||||||||

| Titanium Ti alloys | RM 400 | |||||||||||||||||

| Alpha+beta alloys cured | RM 1050 | 20 – 80 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | ||||

|

Hardened steel | Hardened | 55 HRC | 55 – 65 | ||||||||||||||

| Hardened | 60 HRC | 45 – 55 | ||||||||||||||||

| Chilled cast iron | Cast | 400 | 90 – 105 | |||||||||||||||

| Cast iron | Hardened | 55 HRC | 55 – 65 | |||||||||||||||

- When using long edge type tools, Feed should be reduced to 40% of above table.

MTECS – Small diameter, Short type

| ISO | Workpiece material | Cutting speedCutting speed Vc (m/min) |

Tool diameter | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth fz (mm/t) | |||||||||||||||

| ø1.5 | ø2 | ø3 | ø4 | ø5 | ø6 | ø7 | ø8 | ø9 | ø10 | ø12 | ø14 | ø15 | |||

| Low & mediumLow & medium carbon steels |

60 – 120 | 0.05 | 0.05 | 0.07 | 0.09 | 0.11 | 0.13 | 0.14 | 0.15 | 0.16 | 0.16 | 0.17 | 0.18 | 0.18 | |

| High carbonHigh carbon steels |

60 – 90 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 | 0.12 | 0.13 | 0.14 | 0.14 | 0.16 | 0.17 | 0.18 | |

| Alloy steels,Alloy steels, treated steels |

50 – 80 | 0.04 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.13 | 0.14 | |

| Cast steels | 70 – 90 | 0.04 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.13 | 0.14 | |

| Stainless steels | 60 – 90 | 0.03 | 0.03 | 0.04 | 0.05 | 0.06 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | |

| Cast iron | 40 – 80 | 0.05 | 0.05 | 0.07 | 0.09 | 0.11 | 0.13 | 0.14 | 0.15 | 0.16 | 0.16 | 0.17 | 0.18 | 0.18 | |

| Aluminum | 80 – 150 | 0.05 | 0.05 | 0.07 | 0.09 | 0.11 | 0.13 | 0.14 | 0.15 | 0.16 | 0.16 | 0.17 | 0.18 | 0.18 | |

| Synthetics, duroplastics, thermoplastics | 50 – 200 | 0.1 | 0.11 | 0.12 | 0.14 | 0.16 | 0.18 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.2 | 0.2 | |

| Nickel alloys,Nickel alloys, titanium alloys |

20 – 40 | 0.03 | 0.03 | 0.04 | 0.04 | 0.05 | 0.06 | 0.06 | 0.06 | 0.07 | 0.07 | 0.07 | 0.08 | 0.08 | |

ETTL/ETLN

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

| Low carbon steel | AH725 | 100 – 200 | 0.1 – 0.3 | |

| High carbon steel | AH725 | 70 – 150 | 0.1 – 0.3 | |

| High carbon steels | AH725 | 70 – 170 | 0.1 – 0.3 | |

| Cast steel | AH725 | 70 – 170 | 0.1 – 0.3 | |

| Stainless steel | AH725 | 90 – 140 | 0.1 – 0.3 | |

| Cast iron | AH725 | 60 – 130 | 0.05 – 0.3 | |

| Aluminium alloys | AH725 | 80 – 400 | 0.1 – 0.4 | |

| Heat-resistant alloys | AH725 | 10 – 30 | 0.02 – 0.1 | |

| Titanium alloy | AH725 | 20 – 90 | 0.02 – 0.1 |

- Climb milling is recommended.

Single tooth threading mills

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

| Mild steels / Unhardened steels < 200HB | GH330 | 150 – 200 | 0.3 – 0.4 | |

| Carbon steels / Alloy steels < 300HB | GH330 | 150 – 200 | 0.17 – 0.26 | |

| Die steels < 50HRC | GH330 | 30 – 50 | 0.14 – 0.2 | |

| Stainless steels < 300HB | GH330 | 150 – 200 | 0.05 – 0.12 |

- Climb milling is recommended.

- When threading a blind hole, use a right hand cutter in right-hand rotation. Cut up from the bottom to prevent chip recutting.

- When machining internal threads from the mouth, use the left-hand cutter in left-hand rotation.

TungMeister

| ISO | Workpiece material | Condition | Tensile strength [N/mm2] |

Hardness HB | Cutting speed Vc (m/min) |

Tool diameter | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth fz (mm/t) | ||||||||||||||||||

| AH725 | ø2 | ø3 | ø4 | ø6 | ø8 | ø10 | ø12 | ø14 | ø16 | ø20 | ø25 | ø30 | ||||||

| |

Non-alloy steel and cast steel, free cutting steel | < 0.25 %C | Annealed | 420 | 125 | 100 – 250 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 |

| ≥ 0.25 %C | Annealed | 650 | 190 | 80 – 210 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| < 0.55 %C | Quenched and tempered | 850 | 250 | 65 – 170 | ||||||||||||||

| ≥ 0.55 %C | Annealed | 750 | 220 | 110 – 180 | 0.02 | 0.03 | 0.03 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.15 | 0.18 | ||

| Quenched and tempered | 1000 | 300 | 95 – 160 | 0.02 | 0.03 | 0.03 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 | 0.15 | 0.18 | |||

| Low alloy steel and cast steelLow alloy steel and cast steel (less than 5% of alloying elements) |

Annealed | 600 | 200 | 90 – 160 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Quenched and tempered | 930 | 275 | 65 – 200 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| 1000 | 300 | 70 – 210 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||||

| 1200 | 350 | 95 – 160 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||||

| High alloyed steel, cast steel, and tool steel | Annealed | 680 | 200 | 130 – 170 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Quenched and tempered | 1100 | 325 | 75 – 100 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| Stainless steel and cast steel | Ferritic/martensitic | 680 | 200 | 110 – 170 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | ||

| Martensitic | 820 | 240 | 70 – 155 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |||

| |

Stainless steel | Annealed | 600 | 180 | 85 – 100 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.11 | |

| |

Cast iron nodular (GGG) | Ferritic/martensitic | 180 | 120 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Pearlitic | 260 | 75 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||||

| Grey cast iron (GG) | Ferritic | 160 | 70 – 150 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | |||

| Pearlitic | 250 | 110 – 140 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||||

| Malleable cast iron | Ferritic | 130 | 120 – 160 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | |||

| Pearlitic | 230 | 110 – 140 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.21 | 0.15 | 0.18 | 0.21 | ||||

| |

Aluminum- wrought alloy | Not cureable | 60 | 160 – 300 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Cured | 100 | |||||||||||||||||

| Aluminum-cast,Aluminum-cast, alloyed |

=<12% Si | Not cureable | 75 | 150 – 350 | 0.03 | 0.04 | 0.04 | 0.06 | 0.07 | 0.08 | 0.09 | 0.11 | 0.12 | 0.15 | 0.18 | 0.21 | ||

| Cured | 90 | |||||||||||||||||

| >12% Si | High temperature | 130 | 100 – 250 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.07 | 0.08 | 0.10 | 0.12 | |||

| Copper alloys | >1% Pb | Free cutting | 110 | |||||||||||||||

| Brass | 90 | |||||||||||||||||

| Electrolitic copper | 100 | |||||||||||||||||

| Non-metallic | Duroplastics, fiber plastics | 100 – 400 | 0.05 | 0.06 | 0.07 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.15 | 0.18 | 0.22 | 0.25 | ||||

| Hard rubber | ||||||||||||||||||

| |

High temp. alloys | Fe based | Annealed | 200 | ||||||||||||||

| Cured | 280 | |||||||||||||||||

| Ni or Co based | Annealed | 250 | 20 – 80 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | |||

| Cured | 350 | |||||||||||||||||

| Cast | 320 | |||||||||||||||||

| Titanium Ti alloys | RM 400 | |||||||||||||||||

| Alpha+beta alloys cured | RM 1050 | 20 – 80 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | ||||

| |

Hardened steel | Hardened | 55 HRC | 55 – 65 | ||||||||||||||

| Hardened | 60 HRC | 45 – 55 | ||||||||||||||||

| Chilled cast iron | Cast | 400 | 90 – 105 | |||||||||||||||

| Cast iron | Hardened | 55 HRC | 55 – 65 | |||||||||||||||

- With long edge, reduce feed rate to 40%.

indietro