Radius cutter for 3-dimensional machining due to helical cutting edges

Unique twisted insert geometries assures secure insert clamping for high stability

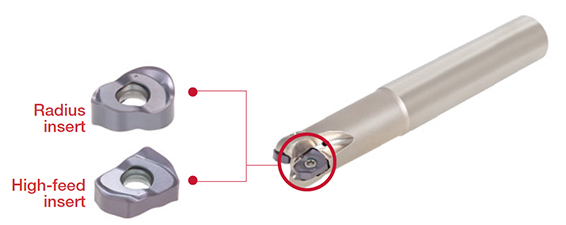

Two types of inserts fit one cutter: radius and high efficiency inserts

Applications & Features

Applications

Features

1. Multi-functional cutter body with superior reliability

• Two types of inserts fit one cutter: radius and high efficiency inserts.

• Secure insert clamping to prevent insert from moving during machining.

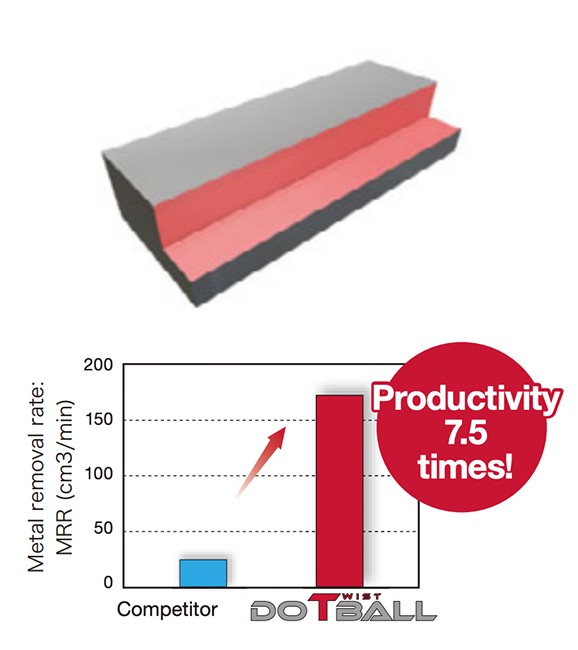

2. High-feed insert with greater depth of cut

• Smooth chip control enables stable machining.

3. Radius insert with high reliability

• Insert cross section is designed to be 2 times as large as that of a round insert.

• Excellent chip evacuation in various applications.

Inserts & Grades

Inserts

LNMX-MJ/LNMX-ML

- Radius insert

- Maximum depth of cut

– LNMU04: 4.0 mm

– LNMU05: 5.0 mm

– LNMU06: 6.0 mm

LNMX-HJ/LNMX-HL

- For High-feed machining

- Maximum depth of cut

– LNMX04: 1.3 mm

– LNMX06: 2 mm

Main Grades

AH8015

![]()

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

Cutter bodies

Practical examples

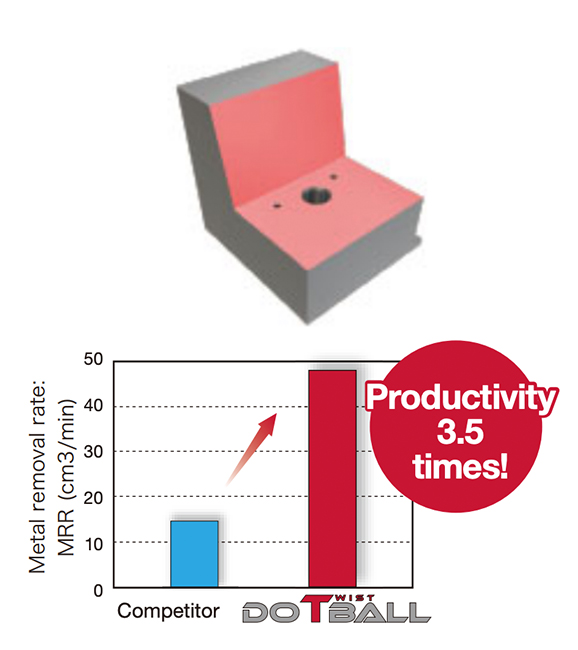

Example #1

General Engineering

| Part: | Fixture part |

| Material: | SUS304 |

| Cutter: | EXLN04M025C25.0R03 ( ø25, z = 3) |

| Insert: | LNMX0405R4-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 220 ← 120 (m/min) fz = 0.4 ← 0.1 (mm/t) Vf = 3360 ← 535 (mm/min) ap = 3.5 ← 3 (mm) ae = 15 (mm) Application: Shoulder milling Coolant: External supply Machine: Vertical M/C |

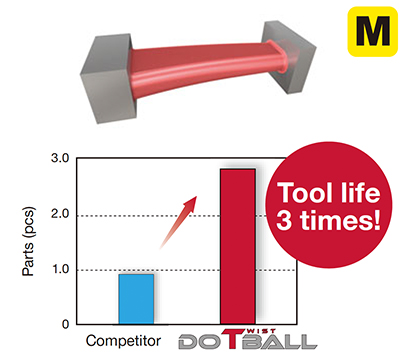

Example #2

Die and Mold Industry

| Part: | Slide core |

| Material: | NAK80 (40HRC) |

| Cutter: | EXLN04M025C25.0R03 ( ø25, z = 3) |

| Insert: | LNMX0405R4-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 150 (m/min) fz = 0.3 ← 0.15 (mm/t) Vf = 1720 ← 573 (mm/min) ap = 4 ← 5 (mm) ae = 7 ← 5 (mm) Application: Shoulder milling Coolant: External supply Machine: Vertical M/C |

Example #3

Power Generation Industry

| Part: | Turbine blade |

| Material: | 13Cr-Mo stainless steel |

| Cutter: | EXLN04M032C32.0R04 (ø32, z = 4) |

| Insert: | LNMX0405R4-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 220 (m/min) fz = 0.30 (mm/t) Vf = 2,626 (mm/min) ap = 1.0 (mm) Application: Profile milling Coolant: Dry Machine: Turning center |

Standard cutting conditions

LNMX**-MJ/ML

| ISO | Workpiece material | Hardness | Priority | Grade | Chip- breaker |

Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, SS400, etc. C15, C20, etc. |

– 200 HB | First choice | AH3225 | MJ | 100 – 300 | 0.2 – 0.6 | ||

| – 200 HB | Low cutting force | AH3135 | ML | 100 – 300 | 0.2 – 0.6 | |||

| Carbon steel, Alloy steel S55C, SCM440, etc. C55, 42CrMoS4, etc. |

– 300 HB | First choice | AH3225 | MJ | 100 – 250 | 0.2 – 0.6 | ||

| – 300 HB | Low cutting force | AH3135 | ML | 100 – 250 | 0.2 – 0.6 | |||

| Prehardened steelPrehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | MJ | 100 – 200 | 0.15 – 0.4 | ||

| 30 – 40 HRC | Low cutting force | AH3135 | ML | 100 – 200 | 0.15 – 0.4 | |||

| Austenitic Stainless steel SUS304, SUS304, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | First choice | AH3135 | MJ | 100 – 200 | 0.2 – 0.6 | ||

| – 200 HB | Low cutting force | AH3135 | ML | 100 – 200 | 0.2 – 0.6 | |||

| Martensitic Stainless steel SUS410, SUS420J1, etc. X12Cr13, X20Cr13, etc. |

– 200 HB | First choice | AH3135 | ML | 100 – 300 | 0.2 – 0.6 | ||

| – 200 HB | Fracture resistance | AH3135 | MJ | 100 – 300 | 0.2 – 0.6 | |||

| Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250 HB | First choice | AH120 | MJ | 100 – 300 | 0.2 – 0.6 | ||

| 150 – 250 HB | Fracture resistance | AH3225 | MJ | 100 – 300 | 0.2 – 0.6 | |||

| Ductile cast iron FCD400, etc. 400-15, 600-3, etc. |

150 – 250 HB | First choice | AH120 | MJ | 80 – 250 | 0.2 – 0.6 | ||

| 150 – 250 HB | Fracture resistance | AH3225 | MJ | 80 – 250 | 0.2 – 0.6 | |||

| Titanium alloy Ti-6AI-4V, etc. | – | First choice | AH3135 | ML | 30 – 60 | 0.15 – 0.6 | ||

| – | Fracture resistance | AH3135 | MJ | 30 – 60 | 0.15 – 0.6 | |||

| Superalloys Inconel718, etc. |

– | First choice | AH8015 | MJ | 20 – 50 | 0.05 – 0.3 | ||

| – | Low cutting force | AH120 | ML | 20 – 50 | 0.05 – 0.3 | |||

| Hardened steel | SKD61, etc.SKD61, etc. X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH3225 | MJ | 50 – 150 | 0.1 – 0.3 | |

| 40 – 50 HRC | Wear resistance | AH8015 | MJ | 50 – 150 | 0.1 – 0.3 | |||

| SKD11, etc. X153CrMoV12, etc. | 50 – 60 HRC | First choice | AH8015 | MJ | 50 – 70 | 0.05 – 0.15 | ||

- When using a long shank or modular head with long overhang, please lower the cutting conditions (Vc, fz, ap) to 70% of the maximum conditions for the standard shank.

LNMX04-HJ/HL

| ISO | Workpiece material | Hardness | Priority | Grade | Chip- breaker |

Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

| Low carbon steel S15C, SS400, etc.S15C, SS400, etc. C15, C20, etc. |

– 300HB | First choice | AH3225 | HJ | 100 – 300 | 0.5 – 1.3 | ||

| Wear resistance | AH8015 | HJ | ||||||

| Low cutting force | AH3225 | HL | 0.4 – 1 | |||||

| Carbon steel, Alloy steel S55C, SCM440, etc.S55C, SCM440, etc. C55, 42CrMoS4, etc. |

– 300HB | First choice | AH3225 | HJ | 100 – 250 | 0.5 – 1.3 | ||

| Wear resistance | AH8015 | HJ | ||||||

| Low cutting force | AH3225 | HL | 0.4 – 1 | |||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40HRC | First choice | AH3225 | HJ | 100 – 200 | 0.4 – 1 | ||

| Wear resistance | AH8015 | HJ | ||||||

| Low cutting force | AH3225 | HL | 0.2 – 0.8 | |||||

| Austenitic Stainless steel SUS304, SUS304, etc.SUS304, SUS304, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200HB | First choice | AH3135 | HL | 100 – 200 | 0.3 – 0.9 | ||

| Fracture resistance | HJ | |||||||

| Martensitic Stainless steel SUS410, SUS420J1, etc.SUS410, SUS420J1, etc. X12Cr13, X20Cr13, etc. |

– 200HB | First choice | AH3135 | HL | 100 – 300 | 0.3 – 0.9 | ||

| Fracture resistance | HJ | |||||||

| Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | AH120 | HJ | 100 – 300 | 0.5 – 1.3 | ||

| Fracture resistance | AH3225 | |||||||

| Ductile cast iron FCD400, etc. 400-15, 600-3, etc. |

150 – 250HB | First choice | AH120 | HJ | 80 – 250 | 0.5 – 1.3 | ||

| Fracture resistance | AH3225 | |||||||

| Titanium alloy Ti-6AI-4V, etc. |

150 – 250HB | First choice | AH3135 | HL | 30 – 60 | 0.3 – 0.7 | ||

| Fracture resistance | HJ | |||||||

| Superalloys Inconel718, etc. |

150 – 250HB | First choice | AH8015 | HL | 20 – 50 | 0.1 – 0.3 | ||

| Fracture resistance | HJ | |||||||

| Hardened steel | SKD61, etc.SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH3225 | HJ | 50 – 150 | 0.1 – 0.5 | |

| Wear resistance | AH8015 | |||||||

| SKD11, etc.SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 | HJ | 50 – 70 | 0.05 – 0.2 | ||

- When using a long shank or modular head with long overhang, please lower the cutting conditions (Vc, fz, ap) to 70% of the maximum conditions for the standard shank.

LNMX06-HJ

| ISO | Workpiece material | Hardness | Priority | Grade | Chip- breaker |

Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

| lLow carbon steel S15C, SS400, etc.S15C, SS400, etc. C15, C20, etc. |

– 300HB | First choice | AH3225 | HJ | 100 – 300 | 0.3 – 1.1 | ||

| Wear resistance | AH8015 | |||||||

| Carbon steel, Alloy steel S55C, SCM440, etc.S55C, SCM440, etc. C55, 42CrMoS4, etc. |

– 300HB | First choice | AH3225 | HJ | 100 – 250 | 0.3 – 1.1 | ||

| Wear resistance | AH8015 | |||||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40HRC | First choice | AH3225 | HJ | 100 – 200 | 0.2 – 0.7 | ||

| Wear resistance | AH8015 | |||||||

| Austenitic Stainless steel SUS304, SUS304, etc.SUS304, SUS304, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200HB | First choice | AH3135 | HJ | 100 – 200 | 0.2 – 0.7 | ||

| First choice | ||||||||

| Martensitic Stainless steel SUS410, SUS420J1, etc.SUS410, SUS420J1, etc. X12Cr13, X20Cr13, etc. |

– 200HB | First choice | AH3135 | HJ | 100 – 300 | 0.2 – 0.7 | ||

| Fracture resistance | ||||||||

| Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | AH120 | HJ | 100 – 300 | 0.3 – 1.1 | ||

| Fracture resistance | AH3225 | |||||||

| Ductile cast iron FCD400, etc. 400-15, 600-3, etc. |

150 – 250HB | First choice | AH120 | HJ | 80 – 250 | 0.3 – 1.1 | ||

| First choice | AH3225 | |||||||

| Titanium alloy Ti-6AI-4V, etc. |

150 – 250HB | First choice | AH3135 | HJ | 30 – 60 | 0.15 – 0.6 | ||

| Superalloys Inconel718, etc. |

150 – 250HB | Wear resistance | AH8015 | HJ | 20 – 50 | 0.05 – 0.3 | ||

| Hardened steel | SKD61, etc.SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | AH3225 | HJ | 50 – 150 | 0.1 – 0.3 | |

| Wear resistance | AH8015 | |||||||

| SKD11, etc.SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | AH8015 | HJ | 50 – 70 | 0.05 – 0.15 | ||

- When using a long shank or modular head with long overhang, please lower the cutting conditions (Vc, fz, ap) to 70% of the maximum conditions for the standard shank.

For more information about this product, visit our online e-catalog or download the product report: