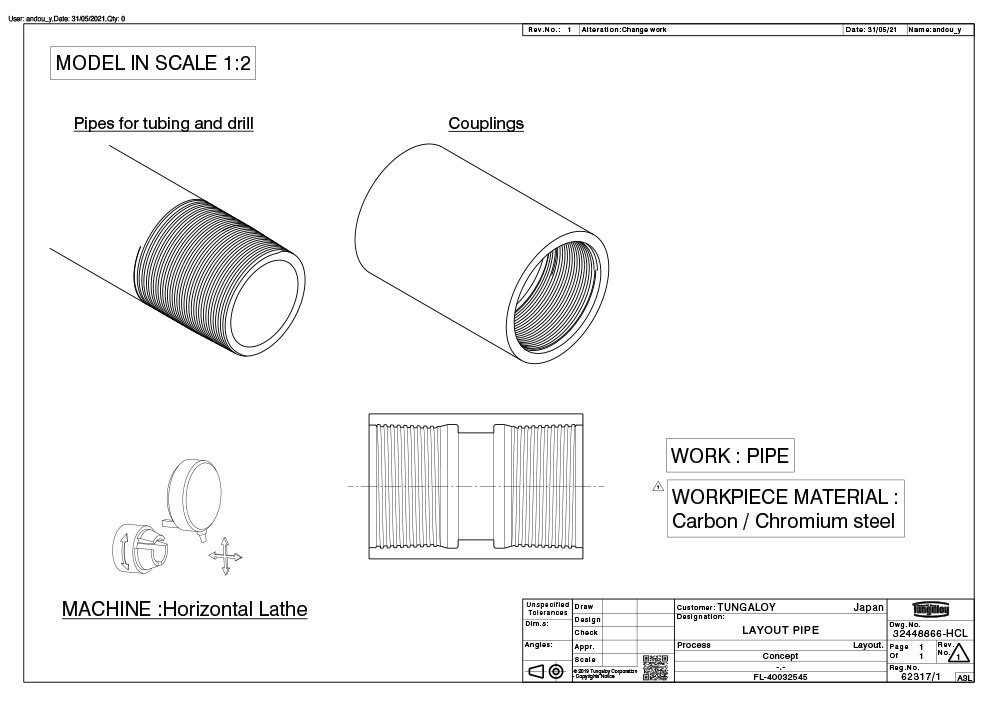

Oil & Gas – Pipe

An oil well pipe refers to a pipeline laid underground or on the surface, designed for the transportation of petroleum, natural gas, and other substances.

The pipes used in oil wells, critical for the extraction and transportation of oil and natural gas, are frequently exposed to extremely harsh environments. These pipes are renowned for their exceptional hardness, durability, and strength, playing a crucial role in the petroleum industry.

Tungaloy’s cutting tools are designed and optimized to align with the characteristics of difficult-to-machine materials. This capability allows for high-quality and precise cutting, significantly improving productivity.

Furthermore, we offer tailored solutions that align with our customers’ specific requirements. Our technical engineers delve into the processing obstacles our customers encounter and deliver the most suitable cutting tools. Alongside this, we provide prompt and efficient customer support to enhance our customers’ satisfaction.

Tooling concepts

- We provide optimal machining solutions, including special adaptations, to meet the requirements of tool consolidation.

- We offer standard sets of chasers for internal and external diameters, compliant with international standards widely used in the oil and gas industry.

- By using a quick-change modular system that can handle composite machining, we can accommodate various machining forms.

Featured process

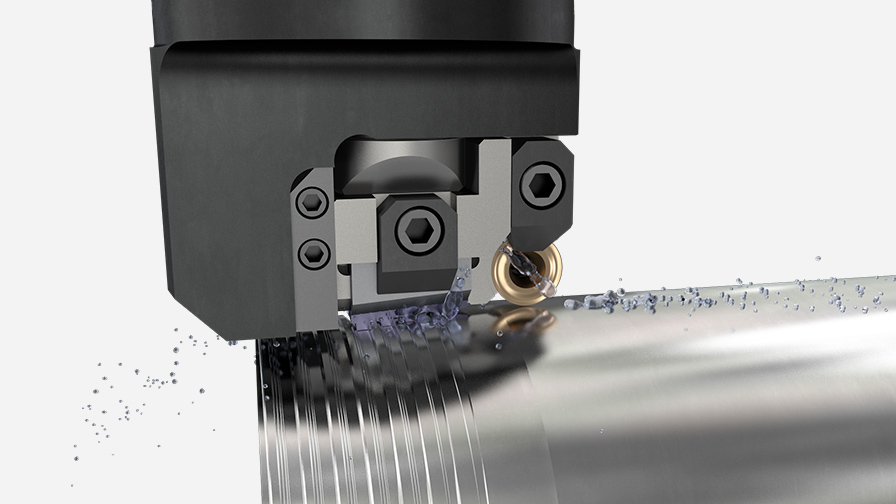

Process 1: External turning and threading

Benefits

- Process consolidation reduces processing time and the number of tools used.

- Achieves high-precision threading.

- Achieves stable long life through enhanced cooling effects with internal coolant.

- Improved repeatability accuracy by using TungCap specifications for tool mounting, significantly reducing downtime during tool changes.

- Responsive to customers’ quality standards based on years of expertise.

CR-5B75-4E

- Provides shapes compliant with international standards for steel pipes, including premium collections and API, ANSI/ASME, GOST, etc.

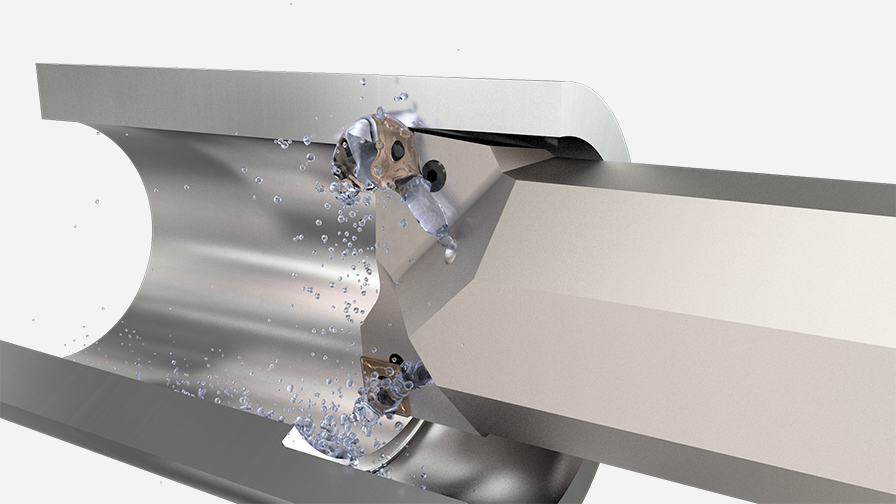

Process 2: Internal turning and face turning

Benefits

- We provide optimal machining solutions, including special adaptations, to meet the requirements of tool consolidation.

- Achieves high-precision and high-quality machining under high-efficiency conditions.

- Achieves high clamping rigidity through the two-sided constraints of polygon taper and flange end face.

![]()

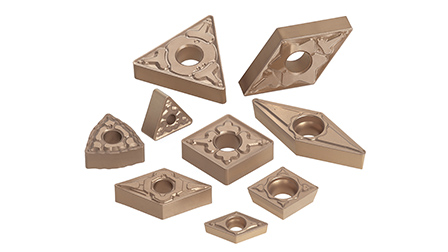

- Next-generation materials enable high-speed cutting.

- The T9215 CVD grade of materials achieved outstanding wear resistance and damage resistance in the ISOP15 material processing area.

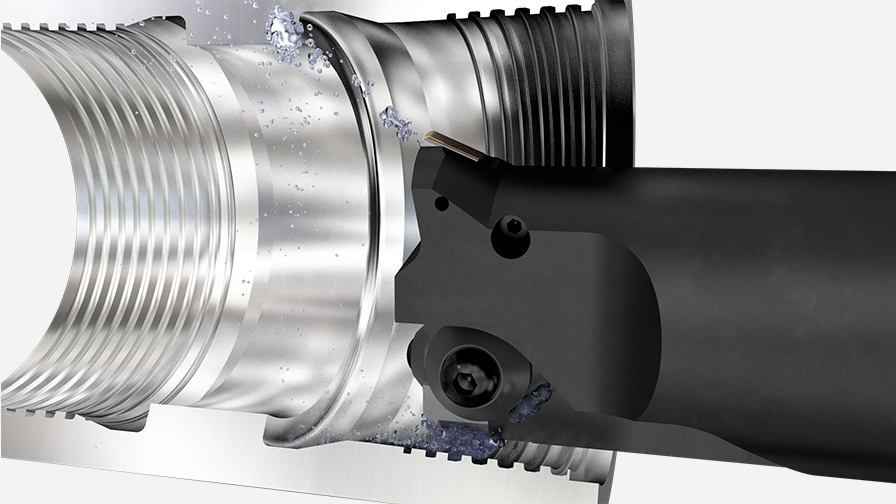

Process 3: Internal turning and threading

Benefits

- Process consolidation reduces processing time and the number of tools used.

- Achieves high-precision threading.

- Achieves stable long life through enhanced cooling effects with internal coolant.

- Improved repeatability accuracy by using TungCap specifications for tool mounting, significantly reducing downtime during tool changes.

- Responsive to customers’ quality standards based on years of expertise.

CR-5B75-4E

- Provides shapes compliant with international standards for steel pipes, including premium collections and API, ANSI/ASME, GOST, etc.