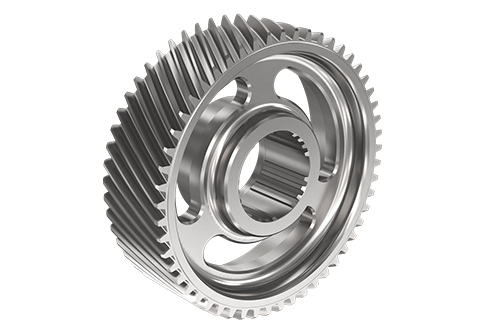

Automotive – Driven Gear

Driven gear, as the name suggests, refers to the gear in a mechanism that receives power.

Typically, it gets its power from the “drive gear” and transmits that power to other parts of the machinery or mechanisms. Gears, also known as cogwheels, transmit power through the meshing of their teeth, a movement that is crucial for countless mechanical devices and equipment. However, this precise process of power transmission cannot be achieved without the right machining techniques.

In the manufacture of gears, relatively soft materials like low carbon steel are often used. Such materials can produce long, continuous chips during cutting, posing risks such as chip entanglement on tools and hindering the proper transport of the workpiece.

Achieving effective chip disposal contributes to the stabilization of the process, maintaining the quality of the driven gear and improving production efficiency. Accurate and efficient machining supports the vital role of the driven gear and is key to maximizing the performance of the entire machine.

Tooling concepts

- Application of high-feed back (pull) turning using AddMultiTurn enables high-efficiency machining.

- Achieve high-efficiency machining with AddForceCut’s high-rigidity even in long overhang operation.

- Improve productivity with the quick tool changes of TungMeister.

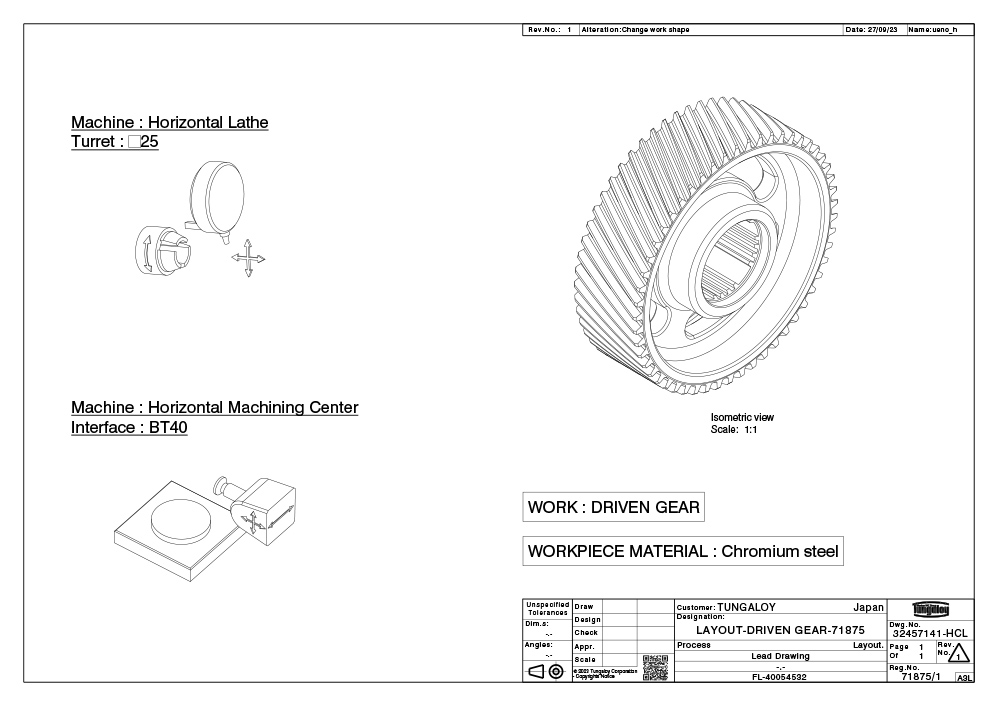

Featured process

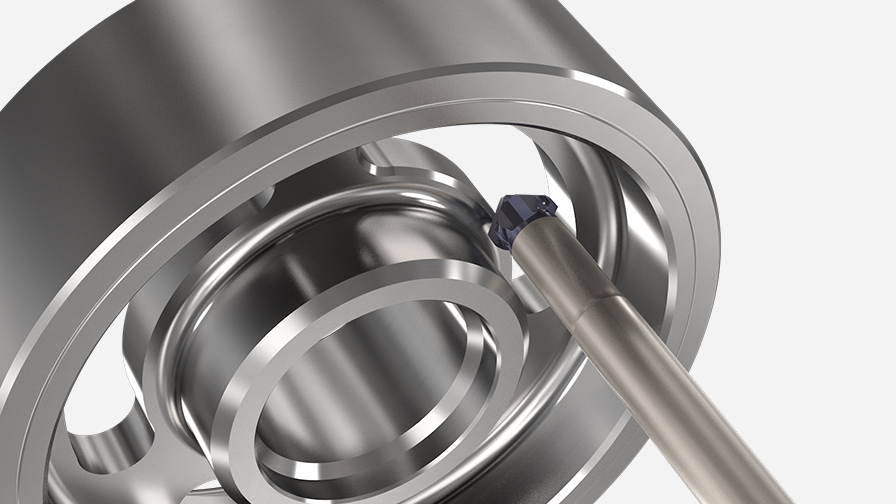

Process 1: Finish external turning and face turning

Benefits

- The high-feed edge geometry with back turning enables highly efficient machining, surpassing conventional ISO tools by approximately 200% in turning operations.

- In rough machining, where high machining efficiency is required, apply back turning, and in finish machining, where surface roughness is critical, apply front turning. By efficiently using two types of cutting edges according to the machining conditions and application, productivity is improved.

- The Y-PRISM insert clamping system, known for its uniqueness and robustness, ensures excellent clamping rigidity. This feature allows for stable multi-directional machining and facilitates high-efficiency processing.

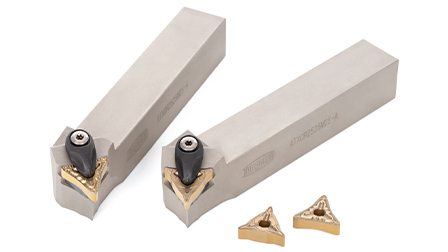

6C-TOMG-TM

- Economical with a double-sided 6-corner specification.

- The T9215 grade ensures exceptional wear and fracture resistance in steel turning operations, providing outstanding performance.

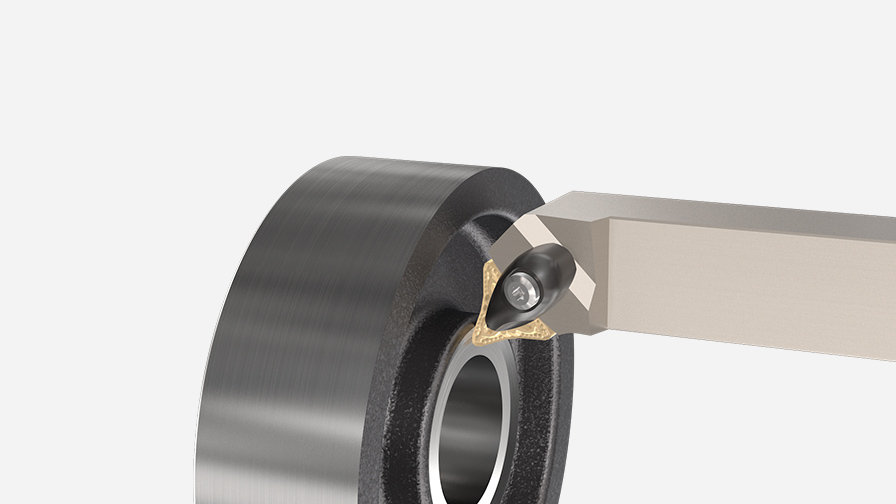

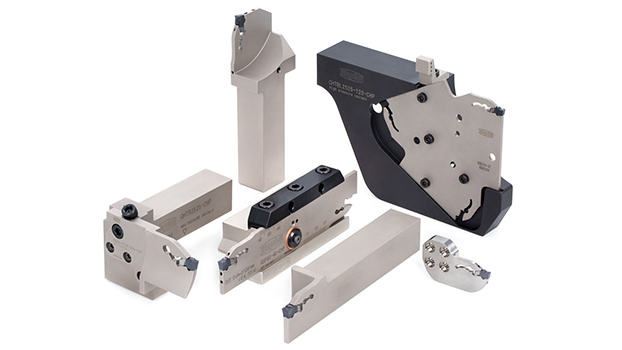

Process 2: Finish face grooving

Benefits

- Apply a high-rigidity holder with increased thickness on the insert back. Provides secure face grooving operation for deep grooves.

- Clamp firmly with optimally positioned clamp screws. High tool rigidity ensures outstanding stability even in end groove milling and lateral feed machining.

- Ensure coolant supply to the groove during machining to promote chip evacuation. Achieve stable machining.

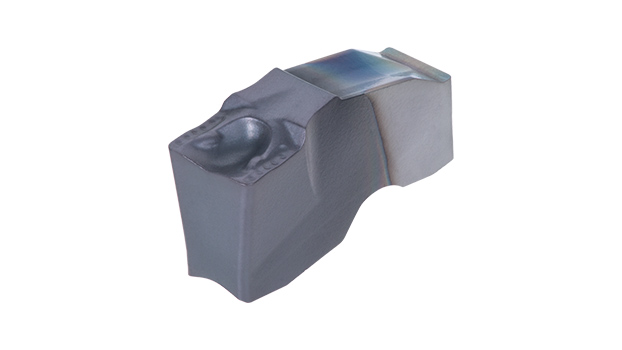

QTX chipbreaker

- Thanks to an optimized position of the protrusions, the chipbreaker is able to capture the chips and forms ideal curls at any feed rate.

- The concave portion at the center of the breaker compresses the width of the chips. Narrowing the width of the chips improves chip evacuation.

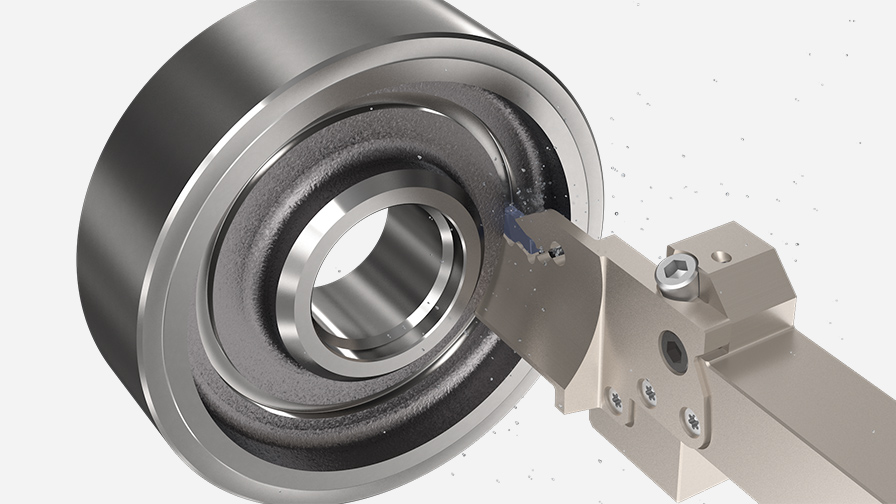

Process 3: Finish slot milling

Benefits

- The rough edge features a wavy roughing cutting edge while having a smaller outer diameter than the finishing edge. This specification allows for achieving finishing surfaces equivalent to square end mills while retaining high productivity due to the anti-vibration performance of roughing end mills.

- Dramatically reduce machine downtime due to head interchangeability. No need for adjustment of protrusion or similar tasks, as only the head needs to be replaced.

- With dual-face constraint of taper and end face, maintain high reproducibility and precision.

![]()

VEE-C head

- A versatile material with both sharp cutting performance and long lifespan.

- Strong coating on sharp edges with high adhesion and excellent edge retention.

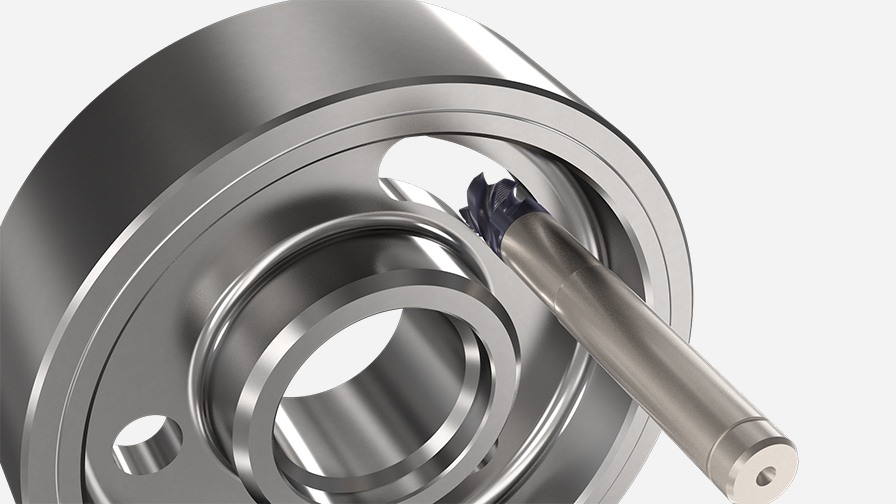

Process 4: Finish chamfering

Benefits

- Applying a VCW head capable of back chamfering in addition to surface chamfering. This allows processing of both the front and back surfaces with the same tool, contributing to tool consolidation.

- Dramatically reduce machine downtime due to head interchangeability. No need for adjustment of protrusion or similar tasks, as only the head needs to be replaced.

- With dual-face constraint of taper and end face, maintain high reproducibility and precision.

![]()

VCW-02 head

- A versatile material with both sharp cutting performance and long lifespan.

- Strong coating on sharp edges with high adhesion and excellent edge retention.