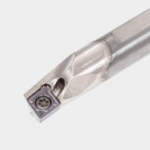

Highly rigid internal toolholder with excellent chip evacuation

Ideal tool geometry has been developed for excellent chip evacuation by extensive structural analysis simulation

Applications & Features

Applications

Features

Engineered for tool strength and optimal chip evacuation

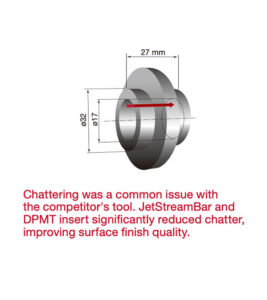

1. Tool body of special alloy steel, designed to reduce chatter

• Ensures superior surface finish quality over conventional ID turning tools.

• Improved tool life, efficiency, and economy.

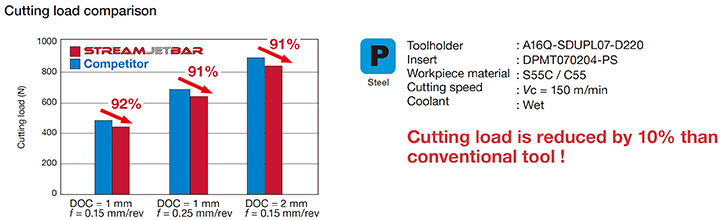

2. Optimal holder design assures low cutting load and high performance in the smallest bore diameters

3. Easy to use

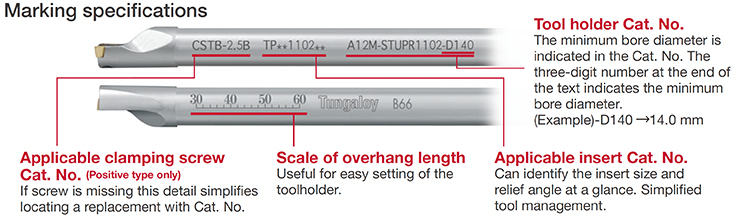

Marking specifications

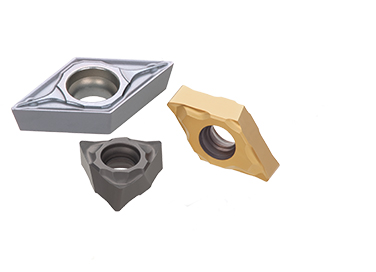

Inserts & Grades

Inserts

Main Grades

T9215

![]()

![]()

![]()

- P10 – P20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

T6130

![]()

- P15 – P30 / M15 – M30

- High wear resistance in cutting at medium to high speed

- First choice for stainless steel

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

Toolholders

Internal turning

StreamJetBar Toolholders

Highly rigid internal toolholder with excellent chip evacuation

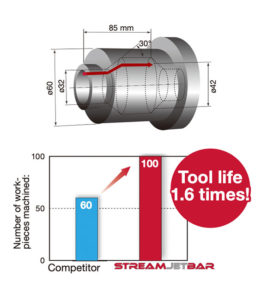

Practical examples

Example #1

General Engineering

| Part: | Machine parts |

| Material: | S35C (C35) |

| Toolholder: | E20S-SDUCR11-D270 |

| Insert: | DCMT11T304-PS |

| Grade: | T9215 |

| Cutting conditions: | Vc = 70 – 160 (m/min) f = 0.12 – 0.2 (mm/rev) ap = 1.0 (mm) Coolant: Wet |

Example #2

Automotive Industry

| Part: | Automotive parts |

| Material: | S45C (C45) |

| Toolholder: | A12M-SDUPL07-D180-P |

| Insert: | DPMT070204-PS |

| Grade: | T9215 |

| Cutting conditions: | Vc = 130 (m/min) f = 0.1 (mm/rev) ap = 1.5 (mm) Coolant: Wet |

Standard cutting conditions

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|---|

| Low carbon steels, Alloy steels |

Medium carbon steels, Alloy steels |

High carbon steels, Alloy steels |

|||||||

| Precision finishing |

Continuous | 01 | NS9530 | 0.05 – 0.5 | 0.03 – 0.15 | 150 – 250 | 80 – 220 | 80 – 180 | |

| Light interrupted | 01 | NS9530 | 0.05 – 0.5 | 0.03 – 0.15 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Finishing | Continuous | PSS | NS9530 | 0.1 – 0.5 | 0.05 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | |

| Light interrupted | PSS | NS9530 | 0.1 – 0.5 | 0.05 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Heavy interrupted | PSS | NS9530 | 0.1 – 0.5 | 0.05 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Finishing to light cutting |

Continuous | PS | NS9530 | 0.3 – 2.0 | 0.08 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | |

| Light interrupted | PS | NS9530 | 0.3 – 2.0 | 0.08 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Heavy interrupted | PS | NS9530 | 0.3 – 2.0 | 0.08 – 0.3 | 150 – 250 | 80 – 220 | 80 – 180 | ||

| Finishing to Medium cutting |

Continuous to Heavy interrupted |

PS | T9215 | 0.5 – 2.5 | 0.08 – 0.3 | 120 – 300 | 100 – 300 | 80 – 250 | |

| PS | T9125 | 0.5 – 2.5 | 0.08 – 0.3 | 120 – 250 | 80 – 180 | 80 – 120 | |||

| Medium cutting | Continuous to Heavy interrupted |

PM | T9215 | 1.0 – 3.0 | 0.15 – 0.3 | 120 – 300 | 100 – 300 | 80 – 250 | |

| PM | T9125 | 1.0 – 3.0 | 0.15 – 0.3 | 120 – 250 | 80 – 180 | 80 – 120 | |||

Low carbon steels, Alloy steels: S10C, SCM415, SS400, SCr420H, etc. C10, 18CrMo4, E275A, 20Cr4, etc. Medium carbon steels, Alloy steels: S45C, SCM440, etc. C45, 42CrMo4, etc. Hi carbon steels, Alloy steels: SNCM439, etc. 41CrNiMo2, etc.

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) |

|---|---|---|---|---|---|---|---|

| Precision finishing | Continuous | Whh | GH330 | 0.05 – 2.0 | 0.03 – 0.2 | 100 – 150 | |

| Finishing | Continuous | PSF | AH725 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 150 | |

| Light interrupted | PSF | AH725 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 150 | ||

| Heavy interrupted | PSF | AH725 | 0.1 – 0.5 | 0.05 – 0.3 | 50 – 120 | ||

| Finishing to light cutting |

Continuous | PSS | AH630 | 0.3 – 2.0 | 0.08 – 0.3 | 90 – 190 | |

| Light interrupted | PSS | AH630 | 0.3 – 2.0 | 0.08 – 0.3 | 90 – 190 | ||

| Heavy interrupted | PSS | AH630 | 0.3 – 2.0 | 0.08 – 0.3 | 90 – 190 | ||

| Finishing to medium cutting |

Continuous | PS | T6130 | 0.5 – 2.5 | 0.08 – 0.3 | 100 – 200 | |

| Light interrupted | PS | AH630 | 0.5 – 2.5 | 0.08 – 0.3 | 90 – 190 | ||

| Heavy interrupted | PS | AH630 | 0.5 – 2.5 | 0.08 – 0.3 | 90 – 190 | ||

| Medium cutting | Continuous | PM | T6130 | 1.0 – 3.0* | 0.15 – 0.3 | 90 – 190 | |

| Light interrupted | PM | AH630 | 1.0 – 3.0* | 0.15 – 0.3 | 90 – 190 | ||

| Heavy interrupted | PM | AH630 | 1.0 – 3.0* | 0.15 – 0.3 | 90 – 190 |

* For CCMT0602 and DCMT0702 type inserts, a p = 0.5 – 2.5

Stainless steels: SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc.

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|---|---|

| Grey cast irons | Ductile cast irons | |||||||

| Finishing | Continuous | CM | T515 | 0.05 – 2.0 | 0.05 – 0.3 | 150 – 700 | 150 – 300 | |

| Heavy interrupted | CM | T515 | 0.05 – 2.0 | 0.05 – 0.3 | 100 – 200 | 100 – 200 | ||

| Medium cutting | Light interrupted | CM | T515 | 0.05 – 2.0 | 0.05 – 0.3 | 100 – 300 | 100 – 250 | |

Grey cast irons: FC250, etc. 250, etc.

Ductile cast irons: FCD450, etc. 450-10S, etc.

| ISO | Operation | Work condition | Chip-breaker | Grade | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | |

|---|---|---|---|---|---|---|---|---|

| Titanium alloys | Ni-base alloys | |||||||

| Finishing | Continuous | PSS | AH8015 | 0.3 – 2.0 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | |

| Light interrupted | PSS | AH8015 | 0.3 – 2.0 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | ||

| Finishing to medium cutting |

Continuous | PS | AH8015 | 0.5 – 2.5 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | |

| Light interrupted | PS | AH8015 | 0.5 – 2.5 | 0.02 – 0.3 | 20 – 150 | 20 – 100 | ||

Ni-base alloys: INCONEL718 etc.

Titanium alloys: Ti – 6Al – 4V etc.