Enhancing Precision in Automatic Lathe Processing: Introducing SH7025 Innovations

Optimizing Precision and Efficiency: Overcoming Challenges in Automatic Lathe Processing

Automatic lathe processing presents daily challenges in achieving precise part production. Among the top priorities for production engineers and operators are ensuring seamless operation and maintaining consistent part quality. However, the reality often diverges from these ideals, posing a significant hurdle in consistently achieving high-quality production efficiently.

To address this challenge, three critical factors take precedence: “establishing stable production,” “ensuring consistent component quality,” and “maximizing machine utilization by minimizing tool change frequency.” These factors serve as cornerstones for optimizing both efficiency and quality in automatic lathe machining processes.

Identifying the key processing challenges hindering these critical objectives becomes essential after understanding the essential missions in automatic lathe processing. These challenges directly impact production efficiency, complicating daily operations and affecting the dependability of the final product.

Three primary machining challenges surface:

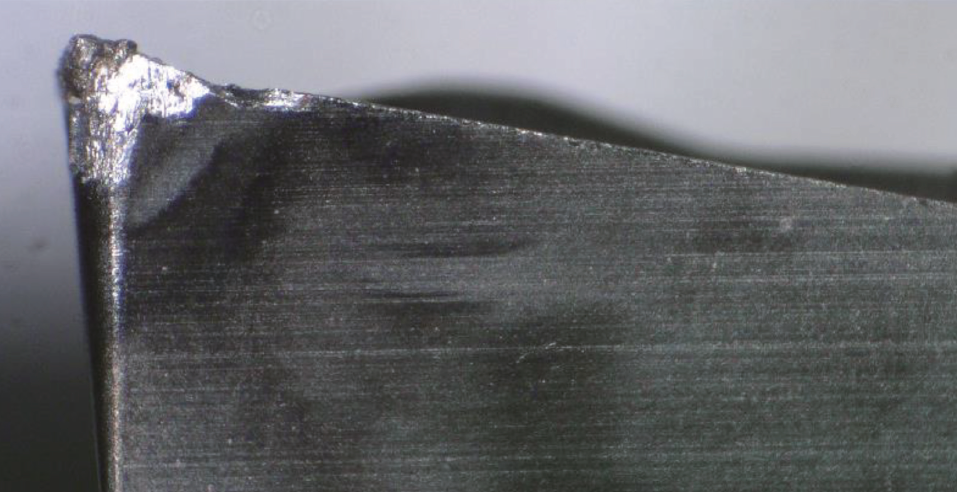

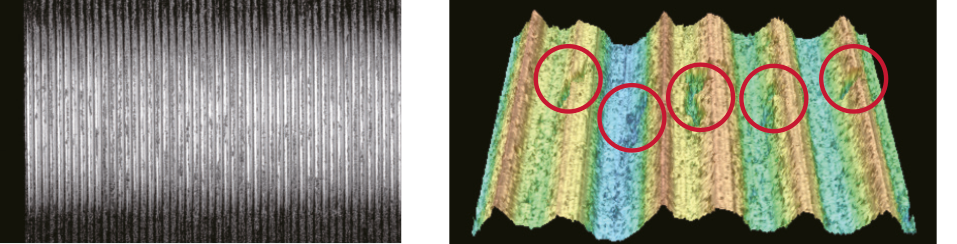

Deteriorating Machined Surface Quality: Frequent machining instances often lead to a decline in quality and surface texture, threatening production stability due to progressive insert wear and resulting adhesion issues.

Compromised Dimensional Accuracy and Burr Formation: Reduced dimensional accuracy and burr formation undermine product quality, primarily due to insert wear, adhesion, and chipping issues.

Inadequate Chip Control: Poor chip management can halt machine operations or damage workpieces, significantly reducing production efficiency primarily due to progressive insert wear.

Addressing these challenges, Tungaloy developed SH7025, introducing advanced characteristics and key technologies to revolutionize automatic lathe processing.

Main Features of SH7025

1- Enhanced Wear Resistance

Significantly prolongs tool life and ensures greater production stability by minimizing wear during machining operations through a TiCN film and columnar crystallization.

SH7025

TiCN coating in columns halts wear advancement

- Prolonging lifespan

- Maintaining superior surface quality

- Preventing dimensional defects

Conventional

Advancing flank wear

- Deteriorating machined surface quality

- Manifestation of dimensional defects

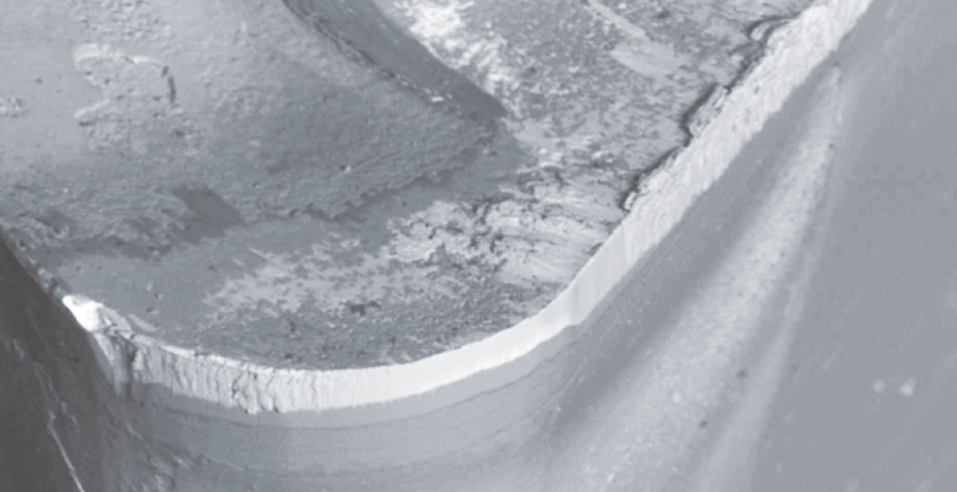

2- Improved Adhesion Resistance

Maintains machined surface quality and reduces burr formation by curbing adhesion occurrences, facilitated by the TiCN coating’s low affinity with iron.

SH7025

Suppression of adhesion

Conventional

Presence of adhesion

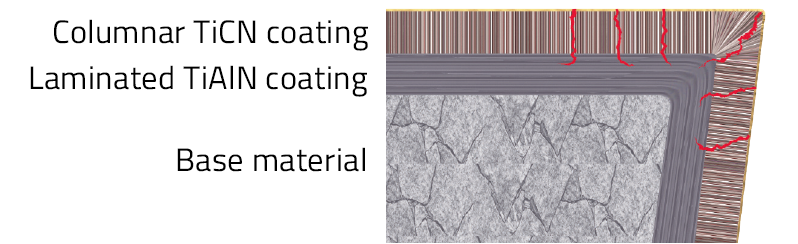

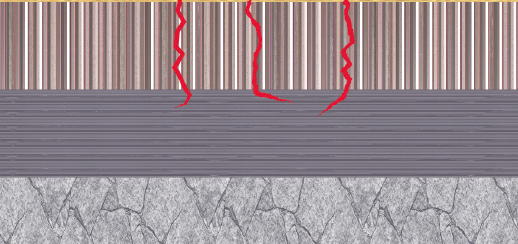

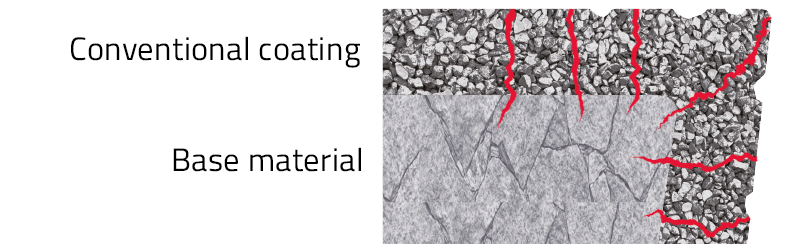

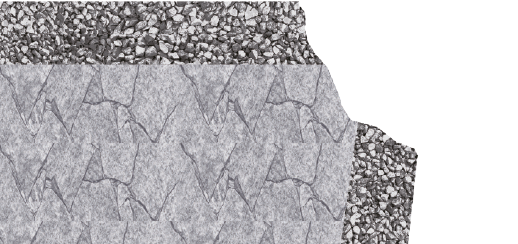

3- Enhanced Fracture Resistance

Critical for preserving sharp cutting edges, minimizing chip control issues, and preventing workpiece scratches through a laminated TiAlN film, minimizing crack progression and cutting edge chipping.

SH7025

Laminated TiAlN suppresses crack growth

Conventional

The crack extends into the base material, resulting in chipping of the cutting edge.

By integrating these innovative features, SH7025 establishes a new benchmark in automatic lathe processing. Real-world user cases demonstrate its effectiveness in resolving machining challenges and enhancing performance.

Success examples addressing primary machining challenges

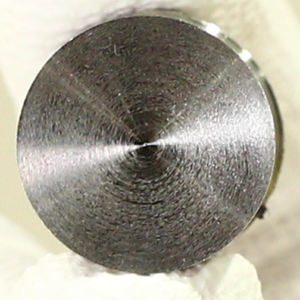

Success example to improve Surface Quality

| Part: | LM guide |

| Material: | SUS316 / X5CrNiMo17-12-3 |

| Insert: | DCGT11T302FN-JP |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 150 (m/min) f = 0.03 (mm/rev) ap = 0.1 (mm) Application: External turning Coolant: Wet |

Result: While competitors’ offerings encountered issues with welding at the cutting edge and diminished machined surface quality, SH7025 effectively prevents welding occurrences and notably prolongs the lifespan of tools.

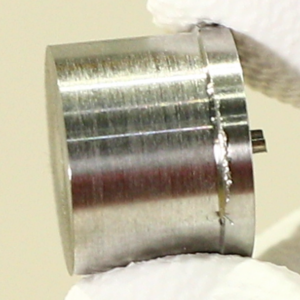

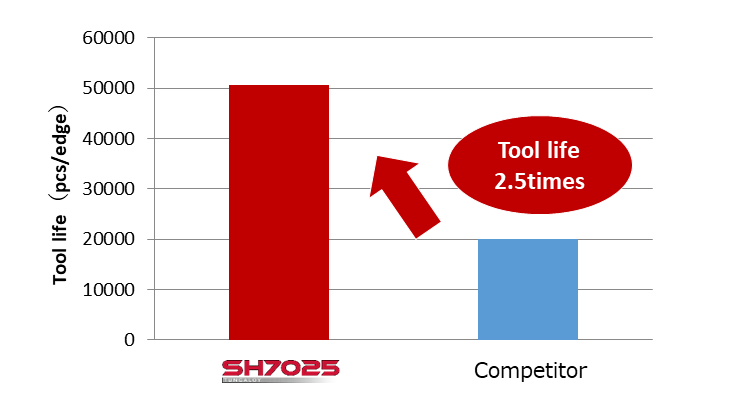

Success example to improve Burr Formation

| Part: | Cylinfer Part |

| Material: | SUS303/X10CrNiS18-9 |

| Insert: | DCGT11T302FN-JP |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 95 (m/min) f = 0.0 (mm/rev) ap = 0.1 (mm) Application: External turning Coolant: Wet |

Result: Competitors’ products experienced burr formation on the workpiece due to chipping at the boundary. SH7025 demonstrates superior chipping resistance, achieving a 2.5 times extension in tool life.

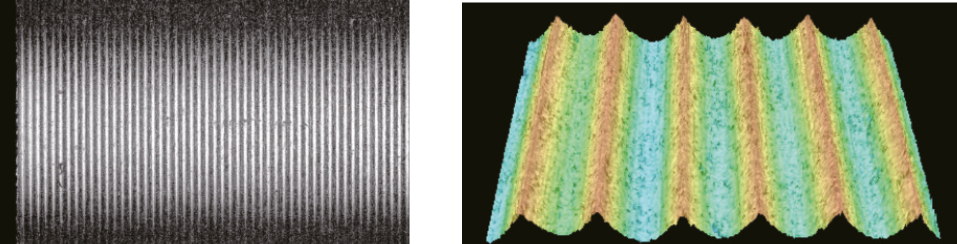

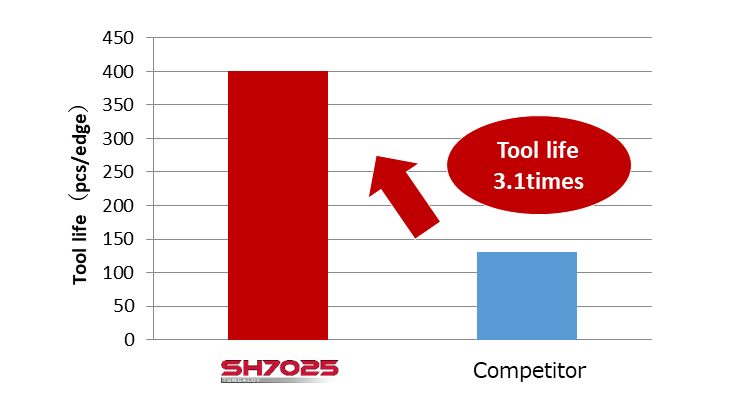

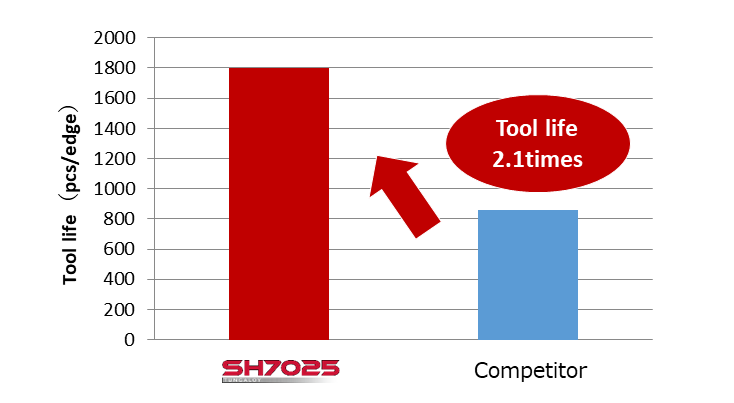

Success example to improve Chip Control

| Part: | Bolt |

| Material: | Soft steel |

| Insert: | DCGT11T304FN-JS |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 93(m/min) f = 0.04 (mm/rev) ap = 1.6 (mm) Application: External turning Coolant: Wet |

Result: As other companies’ products faced challenges with deteriorating machined surface quality as damage ensued, SH7027 demonstrated exceptional stability and prolonged service life, maintaining consistent performance.

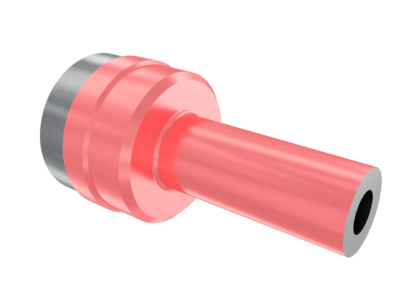

Turning

Cutting edge sharpness is maintained over a long period of time, providing light cutting and excellent surface finish

SH7025

Superior surface quality and process security in small part machining

For those aiming to elevate the quality and efficiency of automatic lathe processing, SH7025 offers an optimal choice. Apply for test samples to experience SH7025’s transformative effects in real production environments.

Request Form