Iwaki, August 2022―Tungaloy has unveiled BR35F extremely fracture resistant coated CBN grade that is developed specifically for heavy interrupted cuts of hardened steel parts.

Gears and spline shafts are common automotive parts made of hardened steel with finish turning operations that involve heavy interrupted cuts. Such operations often cause conventional grade inserts catastrophic failure, posing a challenge for securing tool life predictability. To address the challenge, Tungaloy has created BR35F coated CBN grade that is developed to provide unrivaled fracture resistance in heavy interrupted hard turning operations.

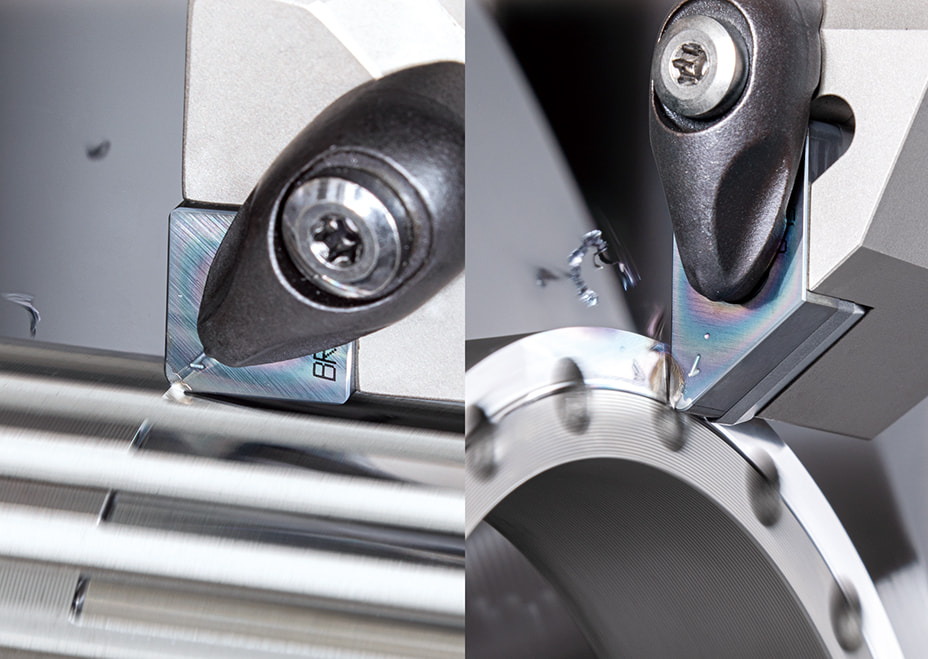

BR35F incorporates a dedicated polycrystalline cubic boron nitride (PcBN) substrate, consisting of evenly distributed ultrafine cubic boron nitride (cBN) grains, that inhibits the generation and propagation of thermal cracks on the cutting edge. The PcBN substrate is coated with a PVD coating developed with Tungaloy’s latest technology that helps prevent microcracks from developing to catastrophic insert failure. This coating substrate combination ensures ultimate reliability and long, predictable tool life during heavy interrupted hard turning operations.

This launch introduces 164 new BR35F grade inserts in a variety of shapes and geometries. On top of standard ISO shapes and sizes in the negative or positive style, the new CBN inserts are available with HP or HS chipbreaker for effective chip breaking in the light D.O.C. range. For applications that involve an aggressive D.O.C. for maximum productivity, the WavyJoint technology provides extra bonding strength of the CBN tips and carbide insert base for process reliability and long tool life. MiniForce-Turn inserts feature a double-sided negative style with cutting edges that enable light cutting action of the positive insert, providing process security for internal turning applications or turning long slender parts susceptible to vibration.

With the addition of BR35F to the existing BXA and BXM grade ranges, Tungaloy completes its CBN product range of hard turning solutions from continuous to heavy interrupted cuts performed in the low to high cutting speed range.

Product information

No. 551-G (Metric)