Iwaki, Japan – January, 2026– Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its SlotMill series and TecMill lineup with two new PVD grades: the versatile AH3225 for stable machining of steel and stainless steel, and the wear-resistant AH8015 for long tool life in difficult-to-cut materials.

Challenges and Trends

In a wide range of industries such as automotive, industrial machinery, construction equipment, and shipbuilding, the trend toward higher product precision and shorter delivery times is accelerating. As a result, improving productivity and reducing tooling costs have become more important than ever. In particular, in machining environments that handle various work materials, challenges such as severe cutting conditions and fluctuations in tool life have become key issues.

Under these circumstances, AH3225, which combines versatility with high reliability, enables stable machining primarily of steel and stainless steel, covering a broad range of applications. Meanwhile, for difficult-to-cut materials such as cast iron, heat-resistant alloys, and hardened steels, the expanded lineup of AH8015, which offers excellent wear resistance, is expected to further improve productivity and reduce tooling costs.

Product Overview

SlotMill Series – TecTangiential slot

Application: Indexable slot milling cutter series for stable slotting and face/back-face milling with excellent chip control.

Features:

- Provides excellent chip control for stable slotting operations and deeper slot machining.

- Economical side cutter design with robust cutting edges for reliable performance.

- Multi-cutting-edge inserts enable high-efficiency machining.

👉 A versatile slot milling solution that improves productivity and stability in deep slotting and other slot milling tasks.

TecMill

Application: Shoulder milling cutter optimized for heavy roughing on medium- to large-sized machines.

Features:

- High-rigidity vertical inserts provide excellent cutting edge strength and consistent performance.

- Large body core thickness increases stability during heavy shoulder milling and rough face milling.

- 4-corner inserts with larger rake angles to reduce cutting resistance.

👉 A tool ideal for stable heavy cutting and rough shoulder milling on medium to large-capacity machining centers.

Benefits and Features

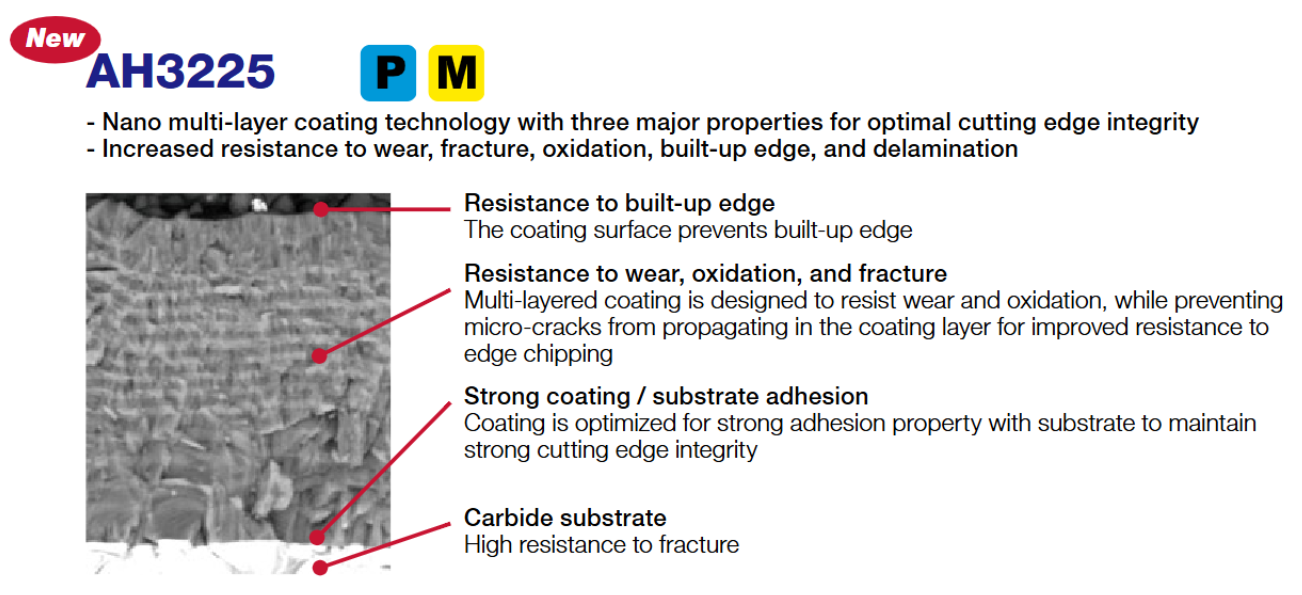

Feature: AH3225 Grade Characteristics

• Excellent combination of wear resistance and fracture resistance provided by a PVD coating with multi-layer nano technology and a tough carbide substrate, delivering long tool life and stable performance in steel and stainless-steel machining.

• Balanced wear resistance with good fracture resistance, enabling stable cutting performance at higher cutting speeds and feeds in a wide range of milling applications.

• Suppresses wear progression to reduce tool change frequency and helps maintain consistent surface quality over long production runs.

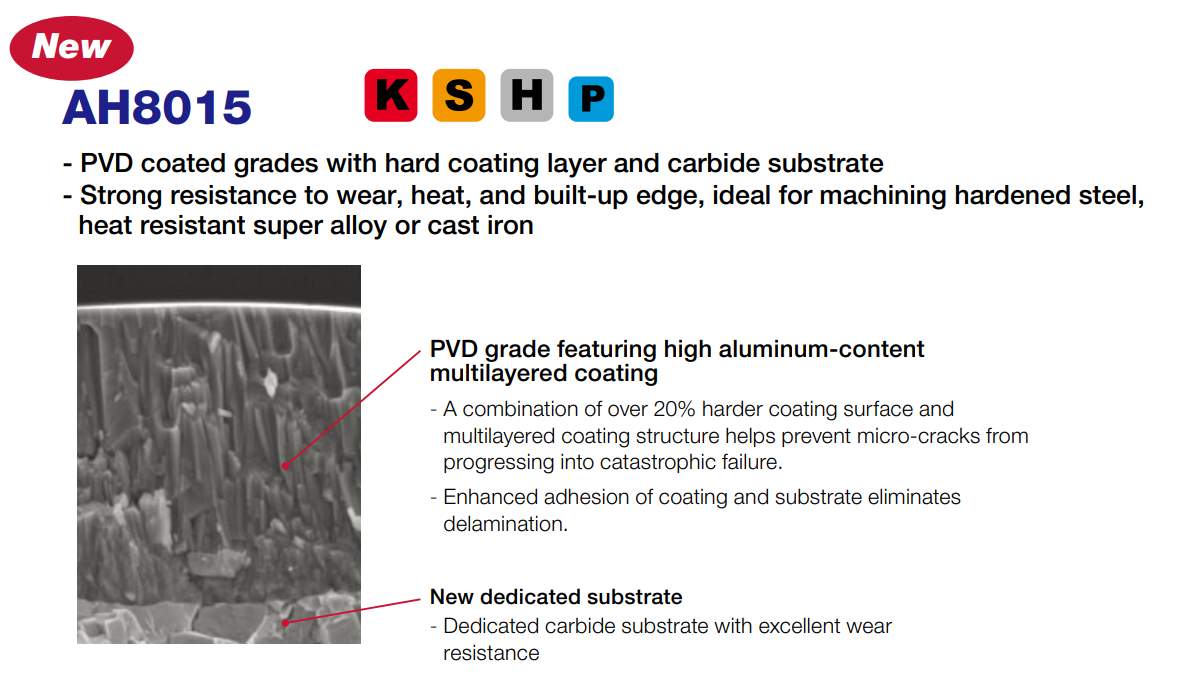

Feature: AH8015 Grade Characteristics

• Features an extremely hard PVD coating combined with a tough carbide substrate, giving the grade high hardness, excellent wear resistance, and strong resistance to chipping in demanding conditions.

• Designed for challenging materials such as cast iron and heat-resistant superalloys, where its high thermal resistance maintains tool life even under high temperatures and heavy loads.

• Delivers stable performance with improved chip control and machining stability across a wide range of cutting conditions, especially in roughing and heavy milling operations.