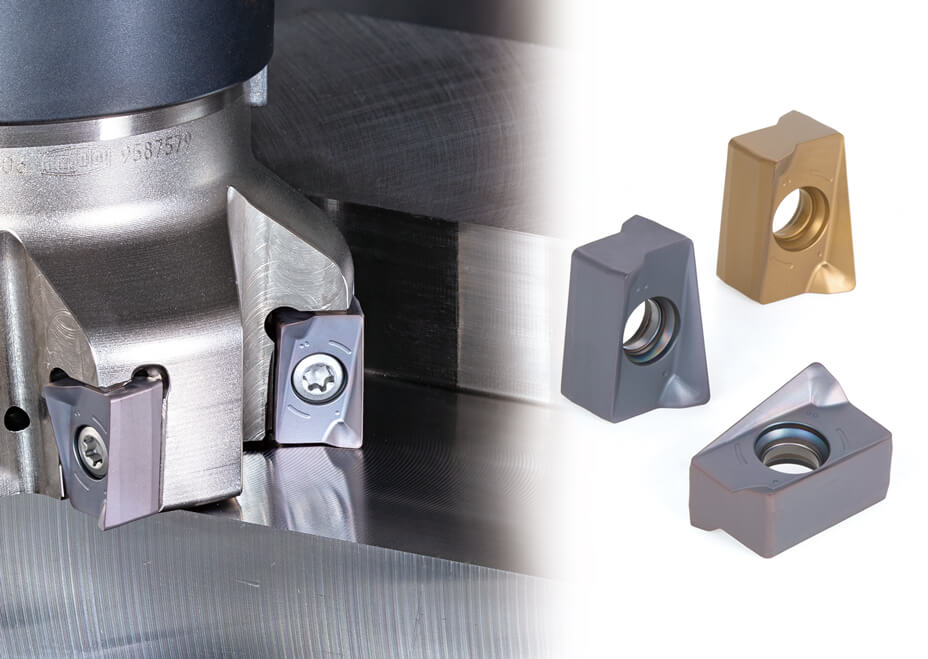

Iwaki, January 2024 — Tungaloy has expanded its DoRec indexable square shoulder milling cutter insert line with a light cutting ML geometry and four latest grades.

DoRec incorporates double-sided, four-edged inserts with superior cutting edge integrity to provide maximum efficiency in various square shoulder milling and slotting operations. The inserts main cutting edge incorporates an innovative design that allows free cutting without compromising the cutting edge integrity, allowing its Size 11 insert for 9 mm (.354″) depth-of-cut maximum (APMX) and Size 18 insert for 16 mm (.630″) APMX.

This expansion adds -ML chipbreaker inserts to the Size 18 insert line. Incorporating a sharp cutting edge, the ML chipbreaker helps prevent the cutting temperatures from increasing in the cutting zone, making it exceptionally suitable not only for the general machining of stainless steel but also for heat resistant superalloys (HRSAs). The chipbreaker also prevents chatter in a long overhang tool setup where the tool is susceptible to vibration.

The insert line has been updated with the four latest grades: AH3225, AH3135, AH8015 physical vapor deposition (PVD) grades and T1215 chemical vapor deposition (CVD) grade. As the first choice in steel, AH3225 provides a balanced combination of wear and fracture resistance. AH3135 boasts superior fracture resistance, making it most suited for machining stainless steel. AH8015 provides the insert with tool life predictability in HRSAs and cast iron. T1215 CVD-coated grade offers excellent wear resistance for high speed machining of cast iron. These four grades are also available on the existing -MJ geometry inserts.

Product information

No. 390S1-G (Metric)

DoRec