Iwaki, Japan – October, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its T9200 series, now featuring the RCMX3209M0 insert for enhanced performance in railway wheel and heavy-duty cutting applications.

Challenges and Trends

In machining applications such as railway wheel processing and general heavy-duty cutting, high cutting performance and stability are essential. However, the RCMX3209M0-shaped insert, which is suitable for these demanding operations, had not been included in the standard lineup of our T9200 series. As a result, under severe cutting conditions, insert chipping or breakage frequently occurred, and in some cases, even led to damage to the tool holder—posing challenges in terms of productivity and cost. In response to these user concerns, there was a strong demand to expand the range of insert shapes to better meet these “Challenges and Market Conditions.”

Product Overview

The T9200 series is a next-generation CVD-coated grade specifically designed for steel turning applications. It combines excellent wear resistance with high toughness, ensuring stable and long tool life. Capable of withstanding high-speed cutting, it is the ideal solution for achieving high-efficiency machining in mass production environments.

Benefits and Features

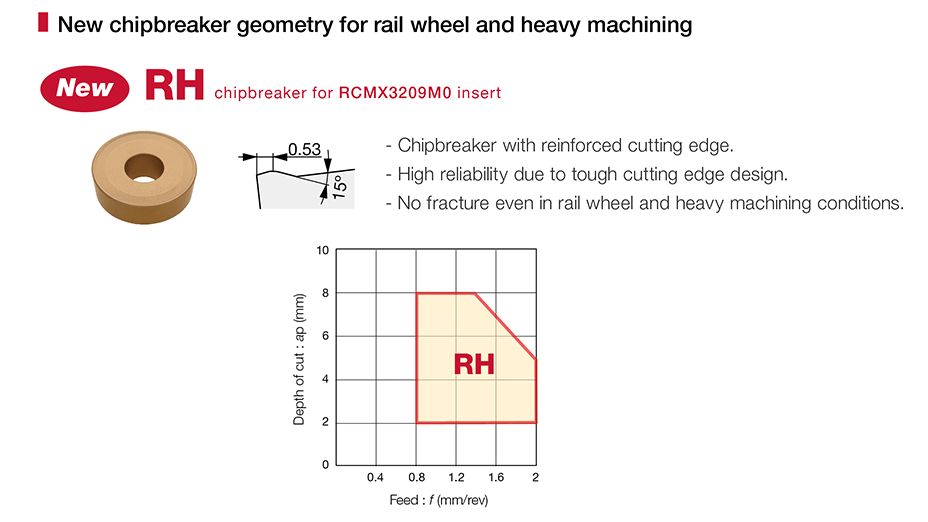

Feature 1: High Machining Stability with Reinforced Cutting Edge Breaker

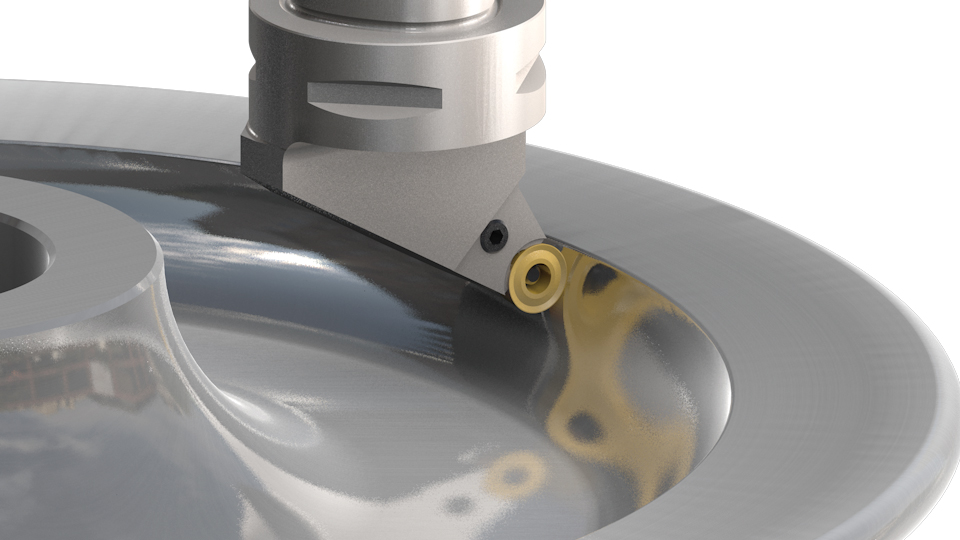

– The RCMX3209M0-RH features the newly developed RH breaker with a robust cutting edge design.

– The reinforced edge prevents chipping and breakage even under high-load conditions such as heavy-duty cutting and railway wheel machining.

– Minimizes machining troubles and ensures reliable continuous operation.

Feature 2: Balanced Wear and Fracture Resistance with T9205 Grade

– T9205 employs a high-hardness substrate and a heat-resistant coating for superior durability.

– In combination with the RH breaker, it delivers long tool life and stable cutting performance.

– Reduces tool change frequency, contributing to cost savings and improved productivity.

Success Stories

IMPROVED TOOL LIFE

New RH chipbreaker with T9205 improved tool life by 1.1 times with well-balanced wear and fracture resistance.

| Industry | Heavy |

| Component | Rail wheel |

| Material ISO code | |

| Work material | Rail wheel steel |

| Machine(Spindletype) | CNC Lathe |

| Tool family | Turning |

| Toolcategory | External & Face turning |

| Product name | T9205 |

| TSR No. | 5407T |