Iwaki, Japan – June, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its solid CBN lineup with the introduction of “SBN30,” a new grade engineered for high-speed machining of cast iron in automotive mass production, offering superior wear resistance, deep cutting capability, and multi-corner design for enhanced productivity and cost efficiency.

Challenges and Trends

In the mass production of automotive components, there is a growing demand for high-speed machining of cast iron parts to improve productivity. In particular, machining operations for brake discs, flywheels, and cast iron gear cases face limitations in durability and cutting speed when using conventional carbide or ceramic tools, making it difficult to enhance overall machining efficiency. Additionally, brazed CBN tip inserts may suffer from delamination during high-speed operations, raising concerns about their reliability. These challenges have driven the need for tools that offer higher durability and greater reliability.

Product Overview

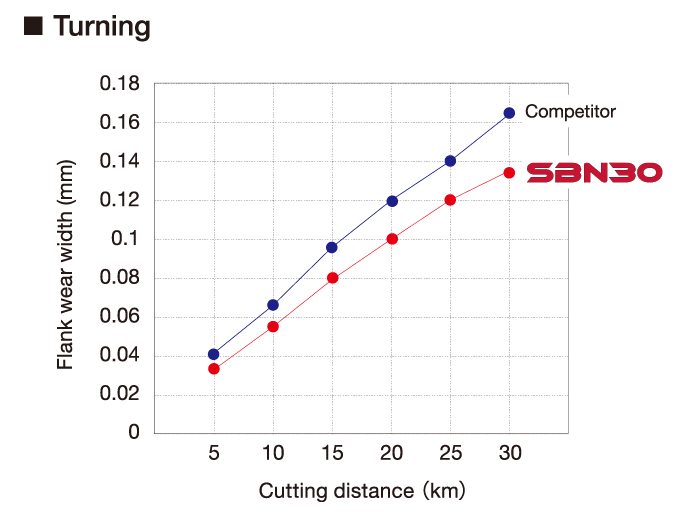

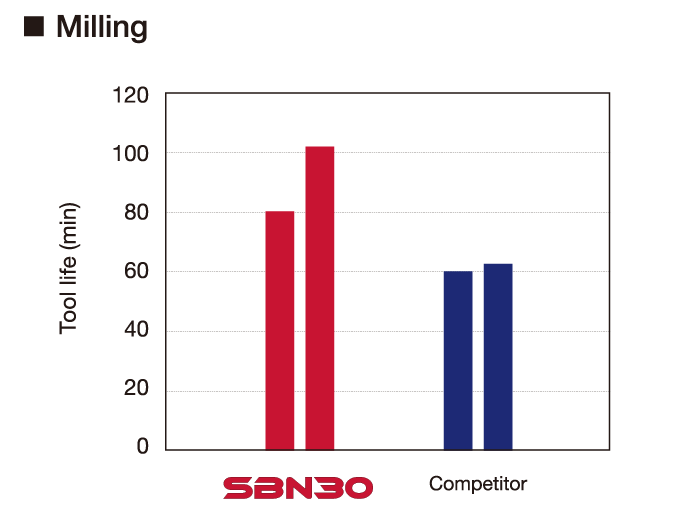

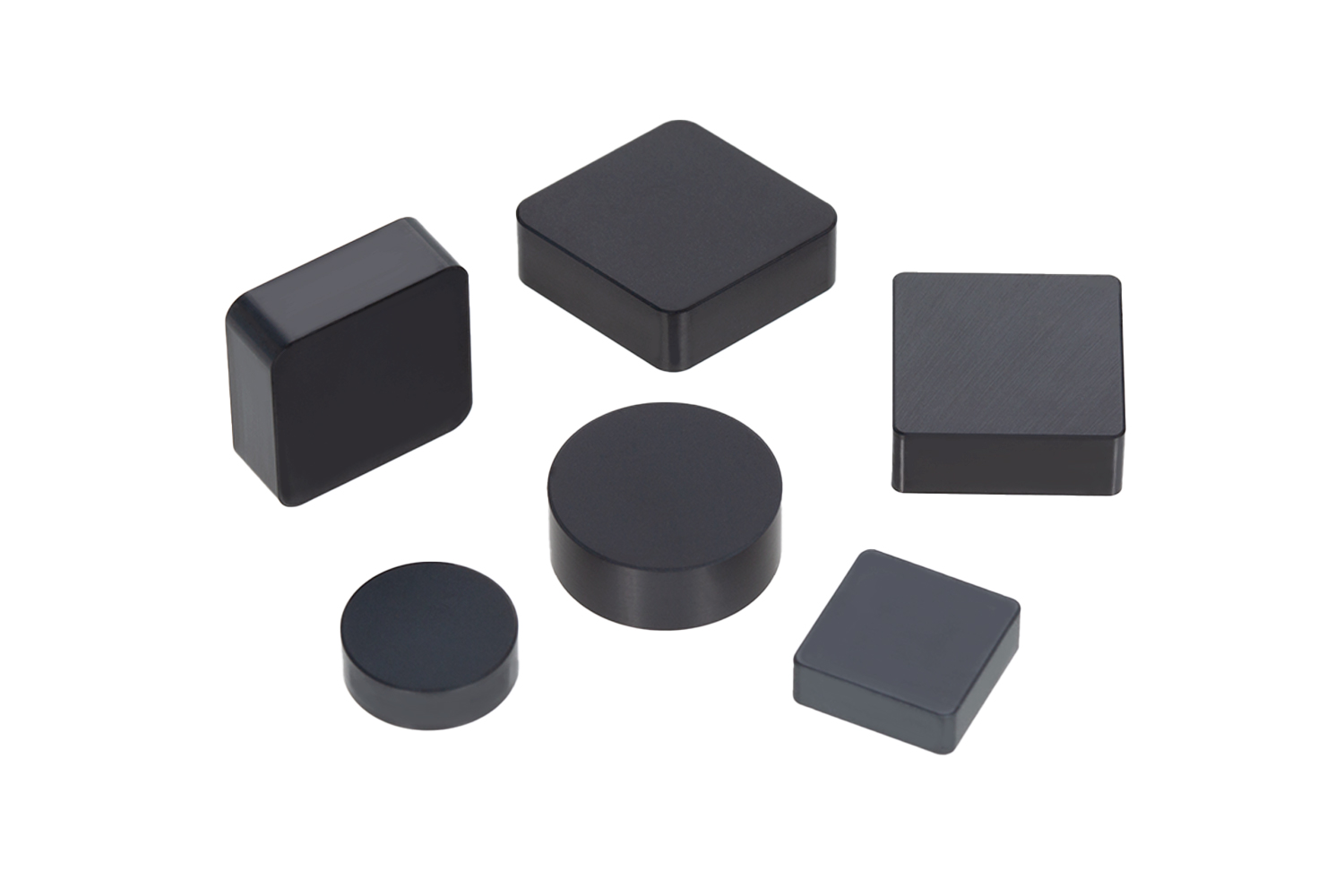

SBN30 is a CBN grade composed of a CBN grain size optimized for cast iron machining and a dedicated binder, offering both excellent wear resistance and high heat resistance.

Benefits and Features

Feature 1: Solid CBN grade for high-speed, high-efficiency machining

– SBN30 enables machining at higher cutting speeds compared to ceramic and carbide tools

– Exhibits excellent wear resistance even under high-temperature conditions, making it ideal for high-speed cast iron machining

– Contributes to reduced machining time and improved productivity

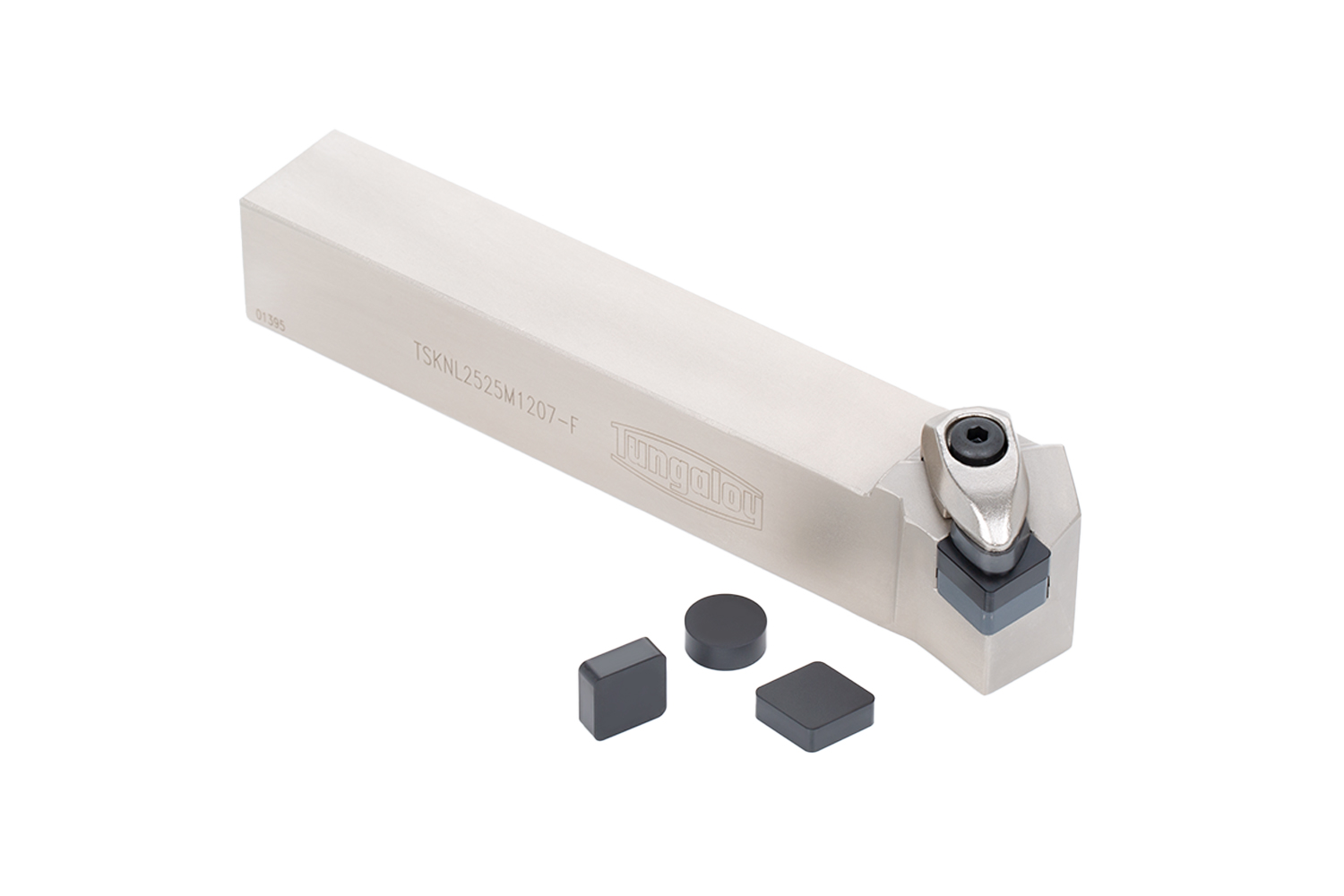

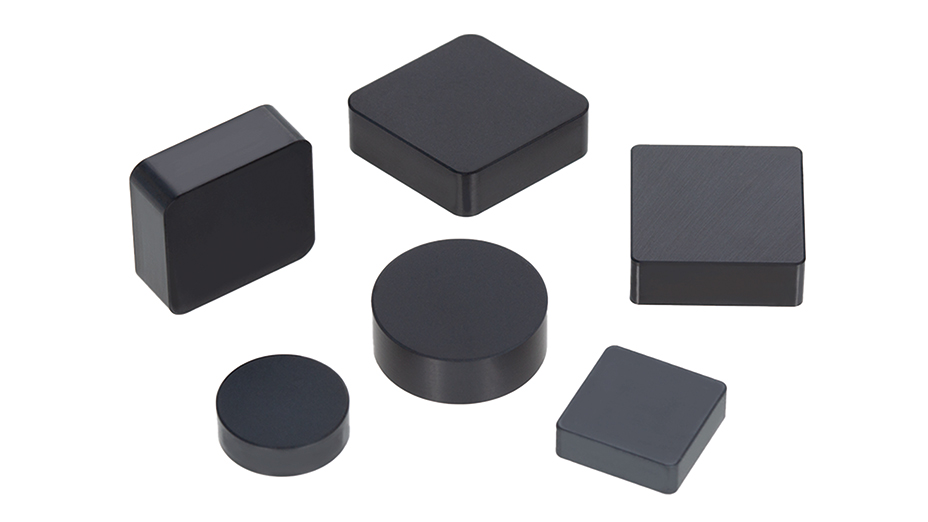

Feature 2: Full CBN construction for deep cutting applications

– The insert is entirely composed of CBN, offering higher strength than brazed types

– Delivers stable performance even under deep cutting and high-load conditions

– Enhances machining flexibility, enabling process reduction and adaptability to complex shapes

Feature 3: Cost-effective multi-corner design

– Designed with more usable corners than brazed CBN tip inserts

– Reduces tool cost per corner, contributing to overall cost reduction