Iwaki, February 2023—Tungaloy has added twelve new coolant-through CHP toolholders to its TungFeed-Blade grooving/parting tool system.

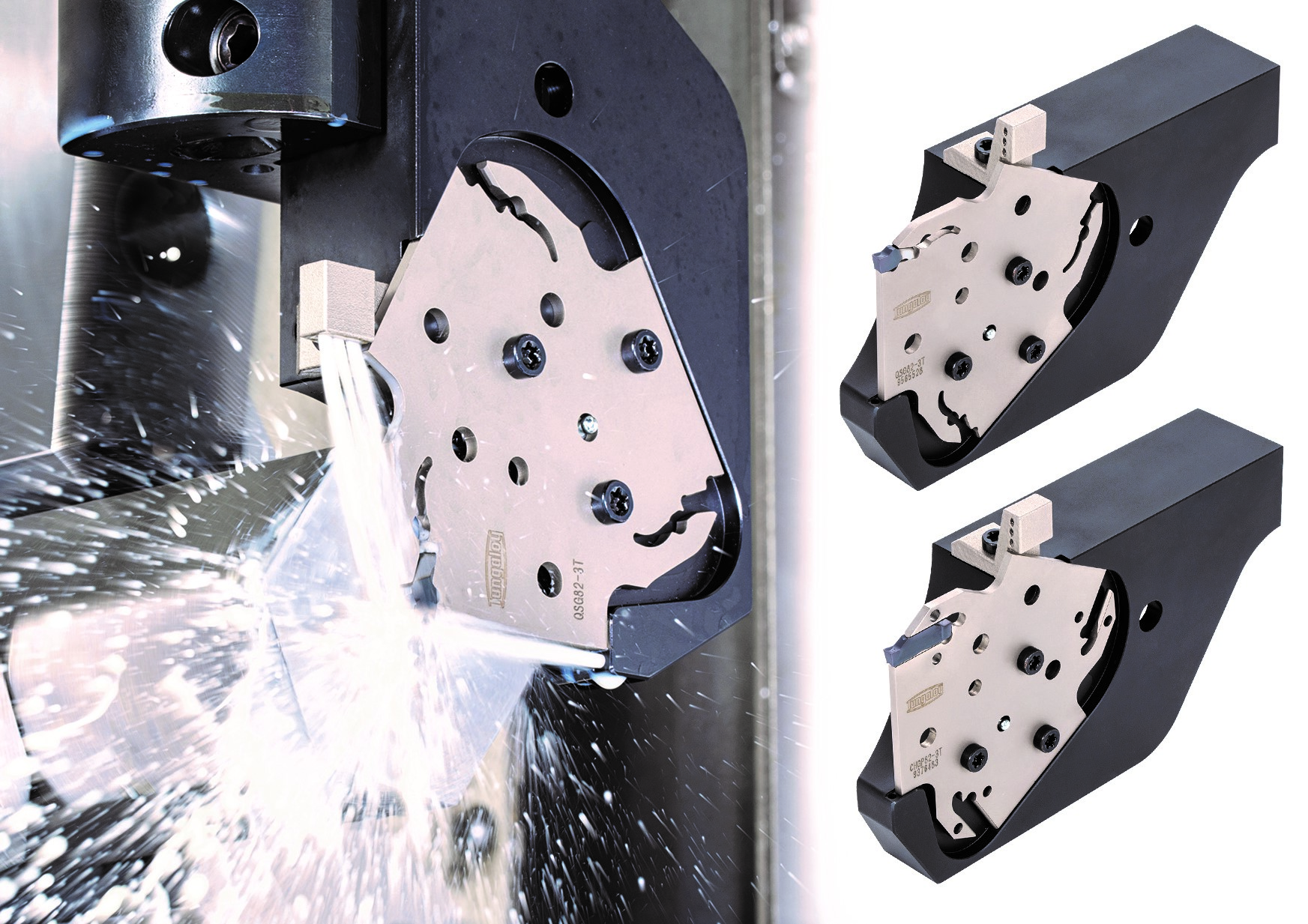

Featuring economical three-pocket blades for carrying TungCut or AddForceCut inserts, combined with unique CHTBR/L toolholders that provide a two-face contact coupling for extra tool durability when mounted on the machine turret, TungFeed-Blade system enables parting and grooving operations at extremely high feed rates. A thick support under the insert pocket provides the insert with stability during aggressive operations, while the three-pocket feature of the blade increases tool economy.

TungFeed-Blade offers two styles of blades: QSG carries AddForceCut grooving and parting inserts and CHGP accommodates TungCut inserts for grooving and parting applications. These blades are interchangeable on a single CHTBR/L toolholder, allowing a broad range of grooving and parting inserts to be applied in various material groups.

TungFeed-Blade now offers CHTBR/L coolant-through toolholders with CHP high-pressure coolant capability. While incorporating the two-face contact coupling for tool rigidity, the new toolholder precisely directs the upper coolant jet to the optimal area of the rake surface, while the second jet flushes the clearance side. Since the new CHTBR/L-CHP toolholders accommodate the existing QSG and CHGP blades, swapping the conventional toolholder with the internal coolant tooling is easy—simply exchange the toolholder and reconnect the coolant pipe. The new CHTBR/L-CHP system will allow parting and grooving applications of bar diameters of up to 120 millimeters (4.724 inches), while promoting smooth chip evacuation and long insert tool life.

Product information

No. 559-G (Metric)