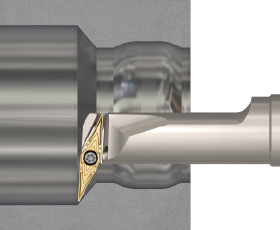

Insert with 25° corner angle for profiling

Y-Pro Series expands the machining range of taper cutting, undercutting, and “V” grooving applications

Applications & Features

Applications

Features

1. A new narrow corner angle insert that expands machining possibilities.

2. Suitable for a wide range of machining applications

Spherical profiling

Face profiling

“ V ” grooving

External undercutting

Internal undercutting

Internal profiling

Inserts & Grades

Inserts

YCGT

- Positive relief angle, G class, 25 deg corner angle insert

YWMT

- Positive relief angle, M class, 25 deg corner angle insert

YNMG

- Negative relief angle, M class, 25 deg corner angle insert

Main Grades

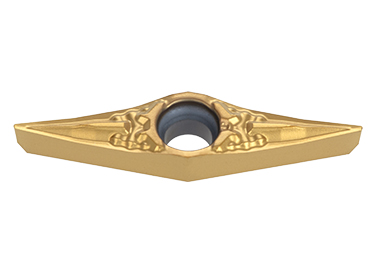

SH7025

![]()

![]()

- The latest grade with sharp cutting edge designed for small part machining.

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

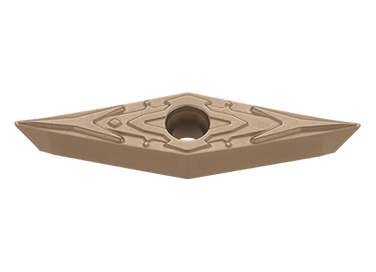

T9215

![]()

![]()

![]()

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

T9225

![]()

![]()

- First choice for roughing to medium cutting

- High fracture resistance

T9235

![]()

- High fracture resistance in heavy interrupted cutting

T6215

![]()

![]()

- High wear resistance at medium to high speed machining

- First choice CVD grade for stainless steel cutting

AH6225

![]()

![]()

- First choice PVD grade for stainless steel machining

- A versatile PVD grade for excellent performance in a wide range of stainless steel applications

AH8015

![]()

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

- First choice for threading

NS9530

![]()

![]()

- High fracture resistance

- Suitable for fi nishing to medium cutting of steel

GT9530

![]()

![]()

- High wear resistance

- Excellent surface quality in finishing

Toolholders

Practical examples

Example #1

| Part: | Fitting |

| Material: | SUS304 / X5CrNi18-10 |

| Tolholder: | JSYJ2CR1212X10 |

| Insert: | YCGT100202MF-JS |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 85 m/min f = 0.03 mm/rev ap = 0.075 mm Application: External turning Coolant: Wet |

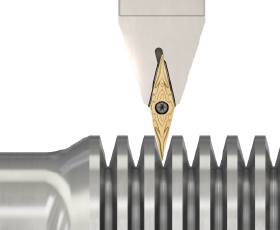

Traditionally, machining the thread-end taper requires a dedicated inser t shape. YCGT performs this operation while delivering 1.75 times longer tool life.

Example #2

| Part: | Shaft |

| Material: | S45C / C45 |

| Tolholder: | QC12-JSYJ2CR10-CHP |

| Insert: | YCGT100202MF-JS |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 70 m/min f = 0.02 mm/rev ap = 0.3 mm Application: External turning Coolant: Wet |

Conventionally, two different tools were required for external turning and profiling.

YCGT integrates both functions into a single tool.

Example #3

| Part: | Pulley |

| Material: | SCM415 |

| Tolholder: | AVVNN2525M16-A |

| Insert: | YNMG160404-ZM |

| Grade: | GT9530 |

| Cutting conditions: | Vc = 250 m/min f = 0.5 mm/rev ap = 0.1 – 0.2 mm Application: External turning Coolant: Wet |

Chip control was drastically inproved against conventional grooving tool. 1.25 times longer tool life achieved.

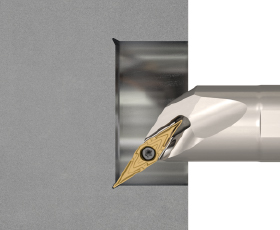

Example #4

| Part: | Automotive part |

| Material: | SACM645 |

| Tolholder: | A16Q-SYUBR11-D200 |

| Insert: | YWMT11T204-ZF |

| Grade: | T9215 |

| Cutting conditions: | Vc = 100 m/min f = 0.5 mm/rev ap = 0.2 mm Application: Internal turning Coolant: Wet |

Chip control and surface finish are improved drastically when internal turning.

Standard cutting conditions

For positive insert

| ISO | Operation | Chipbreaker | Grades | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Low carbon steels, alloy steels |

Medium carbon steels, alloy steels |

High carbon steels, |

||||||

| Precison finishing | JS | SH7025 | 0.5 – 3 | 0.02 – 0.2 | 10 – 200 | 10 – 200 | 10 – 200 | |

| Finishing | ZF | GT9530 | 0.2 – 1.5 | 0.05 – 0.25 | 150 – 300 | 150 – 300 | 150 – 300 | |

| NS9530 | 0.2 – 1.5 | 0.05 – 0.25 | 150 – 300 | 150 – 300 | 150 – 300 | |||

| T9215 | 0.2 – 1.5 | 0.05 – 0.25 | 120 – 350 | 100 – 350 | 80 – 250 | |||

| T9225 | 0.2 – 1.5 | 0.05 – 0.25 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| T9235 | 0.2 – 1.5 | 0.05 – 0.25 | 50 – 200 | 50 – 200 | 50 – 150 | |||

| Finishing to medium |

ZM | GT9530 | 0.5 – 2 | 0.05 – 0.3 | 150 – 300 | 150 – 300 | 150 – 300 | |

| NS9530 | 0.5 – 2 | 0.05 – 0.3 | 150 – 300 | 150 – 300 | 150 – 300 | |||

| T9215 | 0.5 – 2 | 0.05 – 0.3 | 120 – 350 | 100 – 350 | 80 – 250 | |||

| T9225 | 0.5 – 2 | 0.05 – 0.3 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| T9235 | 0.5 – 2 | 0.05 – 0.3 | 50 – 200 | 50 – 200 | 50 – 150 | |||

| Stainless steels | ||||||||

| Precison finishing | JS | SH7025 | 0.5 – 3 | 0.02 -0.2 | 10 – 200 | 10 – 200 | 10 – 200 | |

| Finishing to medium |

ZF | T6215 | 0.2 – 1.5 | 0.05 – 0.25 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 0.2 – 1.5 | 0.05 – 0.25 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| ZM | T6215 | 0.5 – 2 | 0.05 – 0.3 | 140 – 240 | 160 – 280 | 80 – 150 | ||

| AH6225 | 0.5 – 2 | 0.05 – 0.3 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| Cast iron | ||||||||

| Finishing to medium |

ZF | T9215 | 0.2 – 1.5 | 0.05 -0.25 | 140 – 500 | 140 – 500 | 140 – 500 | |

| T9225 | 0.2 – 1.5 | 0.05 – 0.25 | 140 – 500 | 140 – 500 | 140 – 500 | |||

| ZM | T9215 | 0.5 – 2 | 0.05 – 0.3 | 140 – 500 | 140 – 500 | 140 – 500 | ||

| T9225 | 0.5 – 2 | 0.05 – 0.3 | 140 – 500 | 140 – 500 | 140 – 500 | |||

| Heat-resistant alloys | ||||||||

| Finishing to medium |

ZF | AH8015 | 0.2 – 1.5 | 0.05 -0.25 | 20 – 80 | 20 – 80 | 20 – 80 | |

| ZM | AH8015 | 0.5 – 2 | 0.05 -0.3 | 20 – 80 | 20 – 80 | 20 – 80 | ||

For negative insert

| ISO | Operation | Chipbreaker | Grades | Depth of cut ap (mm) |

Feed f (mm/rev) |

Cutting speed: Vc (m/min) | ||

|---|---|---|---|---|---|---|---|---|

| Low carbon steels, alloy steels |

Medium carbon steels, alloy steels |

High carbon steels, |

||||||

| Finishing | ZF | GT9530 | 0.2 – 1.5 | 0.03 – 0.2 | 150 – 300 | 150 – 300 | 150 – 300 | |

| NS9530 | 0.2 – 1.5 | 0.03 – 0.2 | 150 – 300 | 150 – 300 | 150 – 300 | |||

| T9215 | 0.2 – 1.5 | 0.03 – 0.2 | 120 – 350 | 100 – 350 | 80 – 250 | |||

| T9225 | 0.2 – 1.5 | 0.03 – 0.2 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| T9235 | 0.2 – 1.5 | 0.03 – 0.2 | 50 – 200 | 50 – 200 | 50 – 150 | |||

| Finishing to medium |

ZM | GT9530 | 0.7 – 2 | 0.15 – 0.4 | 150 – 300 | 150 – 300 | 150 – 300 | |

| NS9530 | 0.7 – 2 | 0.15 – 0.4 | 150 – 300 | 150 – 300 | 150 – 300 | |||

| T9215 | 0.7 – 2 | 0.15 – 0.4 | 120 – 350 | 100 – 350 | 80 – 250 | |||

| T9225 | 0.7 – 2 | 0.15 – 0.4 | 120 – 300 | 120 – 300 | 100 – 250 | |||

| T9235 | 0.7 – 2 | 0.15 – 0.4 | 50 – 200 | 50 – 200 | 50 – 150 | |||

| Stainless steels | ||||||||

| Finishing | ZF | T6215 | 0.2 – 1.5 | 0.03 – 0.2 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 0.2 – 1.5 | 0.03 – 0.2 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| Finishing to medium |

ZM | T6215 | 0.7 – 2 | 0.15 – 0.4 | 140 – 240 | 160 – 280 | 80 – 150 | |

| AH6225 | 0.7 – 2 | 0.15 – 0.4 | 90 – 200 | 110 – 240 | 60 – 110 | |||

| Cast iron | ||||||||

| Finishing | ZF | T9215 | 0.2 – 1.5 | 0.03 – 0.2 | 140 – 500 | 140 – 500 | 140 – 500 | |

| T9225 | 0.2 – 1.5 | 0.03 – 0.2 | 140 – 500 | 140 – 500 | 140 – 500 | |||

| Finishing to medium |

ZM | T9215 | 0.7 – 2 | 0.15 – 0.4 | 140 – 500 | 140 – 500 | 140 – 500 | |

| T9225 | 0.7 – 2 | 0.15 – 0.4 | 140 – 500 | 140 – 500 | 140 – 500 | |||

| Heat-resistant alloys | ||||||||

| Finishing | ZF | AH8015 | 0.2 – 1.5 | 0.03 – 0.2 | 20 – 80 | 20 – 80 | 20 – 80 | |

| Finishing to medium | ZM | AH8015 | 0.7 – 2 | 0.15 – 0.4 | 20 – 80 | 20 – 80 | 20 – 80 | |

For more information about this product, visit our online e-catalog or download the product report: