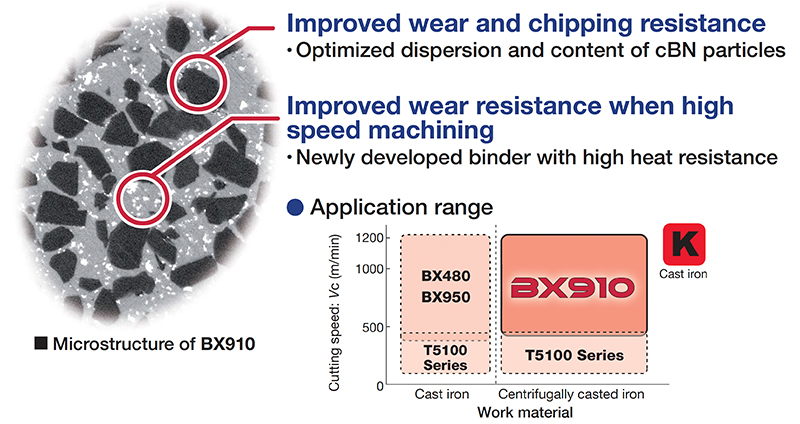

CBN grade for high-speed machining of centrifugally cast iron

Optimum solution for high speed machining of centrifugally casted iron

Applications & Features

Applications

Features

1. Stable and long tool life with high cutting speed

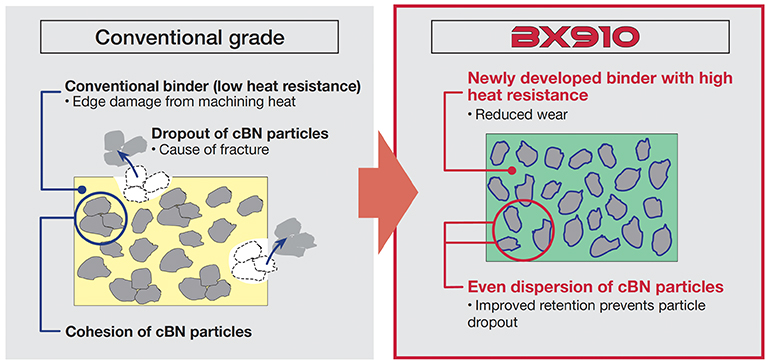

2. Comparison with conventional grade

Grades

BX910

![]()

- Excellent wear resistance in high-speed machining

- Designed for centrifugally cast iron

Practical examples

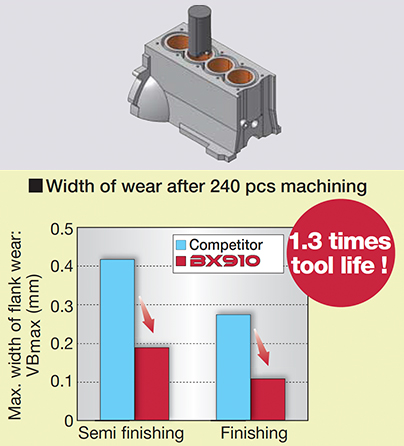

Example #1

Automotive Industry

| Part: | Cylinder liner |

| Material: | Centrifugally casted iron |

| Insert: | 2QP-SPGW120416 |

| Grade: | BX910 |

| Cutting conditions: | Vc = 1000 (m/min) f = 0.3 (mm/rev) ap = Semi finishing: 0.3 (mm) Finishing: 0.03 (mm) Application: Boring Coolant: Wet |

| Machine: |

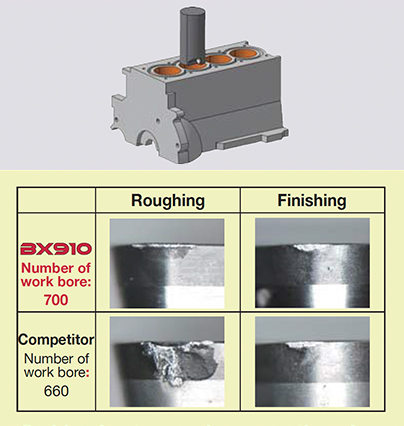

Example #2

Automotive Industry

| Part: | Cylinder liner |

| Material: | Centrifugally casted iron |

| Insert: | 2QP-SPGW120416 |

| Grade: | BX910 |

| Cutting conditions: | Vc = 1000 (m/min) f = 0.4 (mm/rev) ap = Roughing: 0.4 (mm) Finishing: 0.05 (mm) Application: Boring Coolant: Wet |

| Machine: |

Standard cutting conditions

For more information about this product, visit our online e-catalog or download the product report: