flexible turning tool series for CNC automatic lathes and cam-driven lathes

Ideal for machining small parts of 12 mm or smaller diameters

Applications & Features

Applications

Features

Full lineup of shank sizes that can be used in cam-driven and CNC automatic lathes

- Minimum insert movement during machining thanks to the use of optimized screws

- Ground contact faces provide the insert with superior edge repeatability

- 6 x 6 to 10 x 10 mm shanks are available as standard

- Innovative insert clamping mechanism allows the use of the same insert with all toolholders of different sizes

- A flat toolholder design eliminates tool interference with the clamping unit, allowing free tool installations

Applicable for a wide range of applications

- Inserts for parting-off and front turning are available as standard

- Blank inserts are also available for customers to freely fabricate them into the desired groove profiles

- Even when the cutting edge is fractured during machining, the other unused cutting edge is securely protected by unique clamping system

- Right-hand & left-hand inserts

Inserts & Grades

Inserts

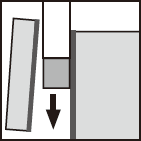

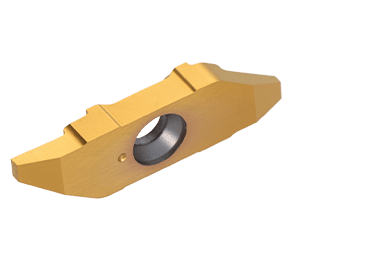

JVPN**R/L Inserts for Parting-off

- CW = 0.5 – 1 mm

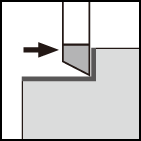

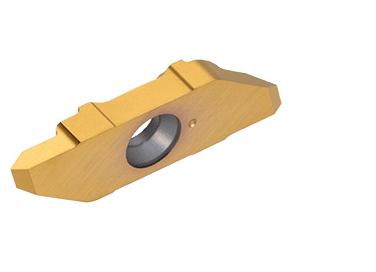

JVFN45R/L Inserts for Front turning

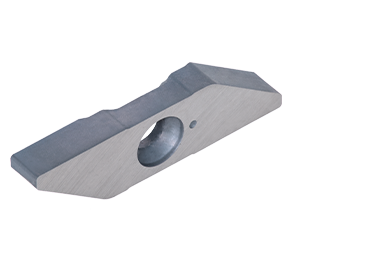

JVNR/L Inserts for Semi-finished blanks

JVBN**R/L Inserts for Back turning

JVGN**R/L Inserts for Grooving

- CW = 0.5 – 1.5 mm

JVTN**R Inserts for Threading

Grades

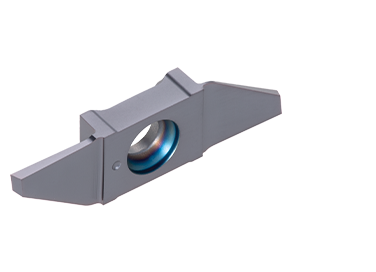

SH7025

![]()

![]()

- The latest grade with sharp cutting edge designed for small part machining.

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

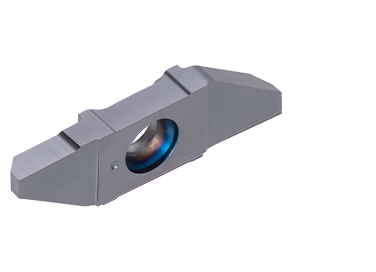

SH725

![]()

![]()

- High wear resistance

- Designed for machining steel and stainless steel

KS15F

![]()

- N15

- Uncoated cemented carbide

Toolholders

Parting-off & Front turning

DuoForceCut Toolholders

flexible tool series with unique insert clamping system

Practical examples

Example #1

| Part: | Engine part |

| Material: | SUS316L |

| Toolholder: | JSXXR0707X05 |

| Insert: | JVPN12R10F000-20 |

| Grade: | SH725 |

| Cutting conditions: | Vc = 75 (m/min) f = 0.03 (mm/rev) CW = 1 (mm) Application: Parting off Coolant: Oil |

Example #2

| Part: | Timepiece part |

| Material: | SK4 |

| Toolholder: | JSXXR0808H05 |

| Insert: | JVPN12R08F000-20 |

| Grade: | SH725 |

| Cutting conditions: | Vc = 50 (m/min) f = 0.01 (mm/rev) CW = 0.8 (mm) Application: Parting off Coolant: Oil |

Standard cutting conditions

Back turning

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH7025 | 50 – 180 | 0.01 – 0.03 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH7025 | 50 – 180 | 0.01 – 0.03 | |

| Free cutting steels SUH22, SUH23, etc. |

SH7025 | 50 – 180 | 0.01 – 0.03 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH7025 | 50 – 120 | 0.01 – 0.03 |

|

Aluminium alloys A5056, A6061, etc. |

SH7025 | 150 – 200 | 0.01 – 0.03 |

| Copper alloys C2600, C280C, etc. |

SH7025 | 100 – 200 | 0.01 – 0.03 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.03 |

| Superalloys Inconel718, etc. |

SH7025 | 30 – 80 | 0.01 – 0.03 |

Grooving

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH7025 | 50 – 180 | 0.01 – 0.05 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH7025 | 50 – 180 | 0.01 – 0.05 | |

| Free cutting steels SUH22, SUH23, etc. |

SH7025 | 50 – 180 | 0.01 – 0.05 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH7025 | 50 – 120 | 0.01 – 0.05 |

|

Aluminium alloys A5056, A6061, etc. |

SH7025 | 150 – 200 | 0.01 – 0.05 |

| Copper alloys C2600, C280C, etc. |

SH7025 | 100 – 200 | 0.01 – 0.05 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.05 |

| Superalloys Inconel718, etc. |

SH7025 | 30 – 80 | 0.01 – 0.05 |

Threading

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH7025 | 50 – 180 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH7025 | 50 – 180 | |

| Free cutting steels SUH22, SUH23, etc. |

SH7025 | 50 – 180 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH7025 | 50 – 120 |

|

Aluminium alloys A5056, A6061, etc. |

SH7025 | 150 – 200 |

| Copper alloys C2600, C280C, etc. |

SH7025 | 100 – 200 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH7025 | 30 – 80 |

| Superalloys Inconel718, etc. |

SH7025 | 30 – 80 |

Parting-off

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH725 | 50 – 180 | 0.01 – 0.05 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 50 – 180 | 0.01 – 0.05 | |

| Free cutting steels SUH22, SUH23, etc. |

SH725 | 50 – 180 | 0.01 – 0.05 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH725 | 50 – 120 | 0.01 – 0.05 |

|

Aluminium alloys A5056, A6061, etc. |

SH725 | 150 – 200 | 0.01 – 0.05 |

| Copper alloys C2600, C280C, etc. |

SH725 | 100 – 200 | 0.01 – 0.05 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH725 | 30 – 80 | 0.01 – 0.05 |

| Superalloys Inconel718, etc. |

SH725 | 30 – 80 | 0.01 – 0.05 |

Front turning

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Low carbon steels S15C, SS400, etc. C15E4, E275A, etc. |

SH725 | 50 – 180 | 0.01 – 0.03 |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 50 – 180 | 0.01 – 0.03 | |

| Free cutting steels SUH22, SUH23, etc. |

SH725 | 50 – 180 | 0.01 – 0.03 | |

|

Stainless steels SUS304, X5CrNi18-9, etc. |

SH725 | 50 – 120 | 0.01 – 0.03 |

|

Aluminium alloys A5056, A6061, etc. |

SH725 | 150 – 200 | 0.01 – 0.03 |

| Copper alloys C2600, C280C, etc. |

SH725 | 100 – 200 | 0.01 – 0.03 | |

|

Titanium alloys Ti-6AI-4V, etc. |

SH725 | 30 – 80 | 0.01 – 0.03 |

| Superalloys Inconel718, etc. |

SH725 | 30 – 80 | 0.01 – 0.03 |

For more information about this product, visit our online e-catalog or download the product report: