Iwaki, Japan – studeni 2025. – Tungaloy Corporation (predsjednik: Satoshi Kinoshita; sjedište: Iwaki City, prefektura Fukushima) najavljuje proširenje TungCut serije uvođenjem dvije nove kvalitete: visokootprne na trošenje AH8005 i visokootporne na lom AH6235.

Izazovi i trendovi

Operacije urezivanja i odrezivanja neizostavni su procesi u općoj strojogradnji i proizvodnji automobilskih komponenti. Međutim, ove operacije često uključuju zahtjevne uvjete obrade poput obrade isprekidanih profila ili dugih prepusta, što može dovesti do izazova smanjene trajnosti alata i stabilnosti sustava.

Na današnjem tržištu, gdje su produktivnost i optimizacija troškova ključni, daljnje poboljšanje performansi alata postalo je najvažniji čimbenik. Kako bi se zadovoljili ti zahtjevi, s nestrpljenjem se očekuje uvođenje novih vrsta reznih alata, koji imaju veću trajnost i stabilni su u radu.

Pregled proizvoda

TungCut je alat za urezivanje i odrezivanje s izvrsnom kontrolom strugotine i krutim stezanjem pločice. Postiže visokokvalitetnu završnu obradu i prikladan je za širok raspon obrade. Kombinira stabilnu preciznost s dugim vijekom trajanja alata.

Prednosti i značajke

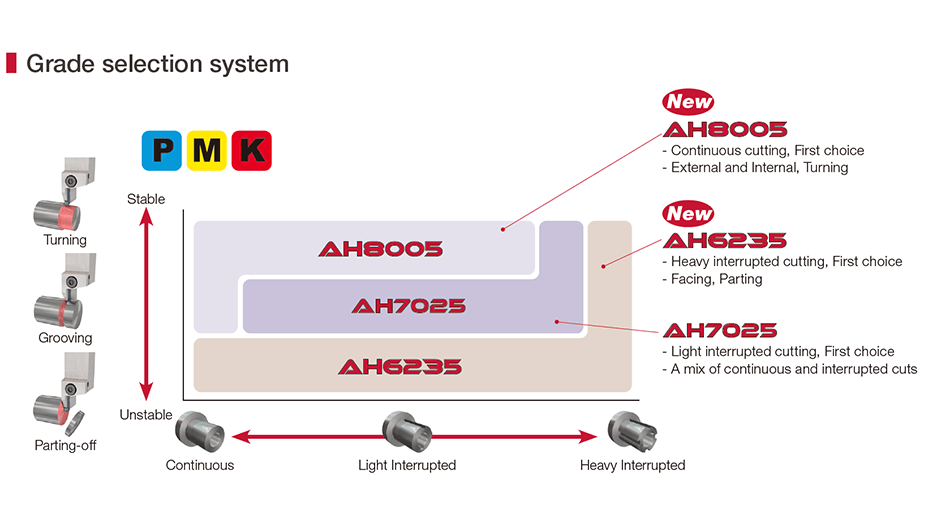

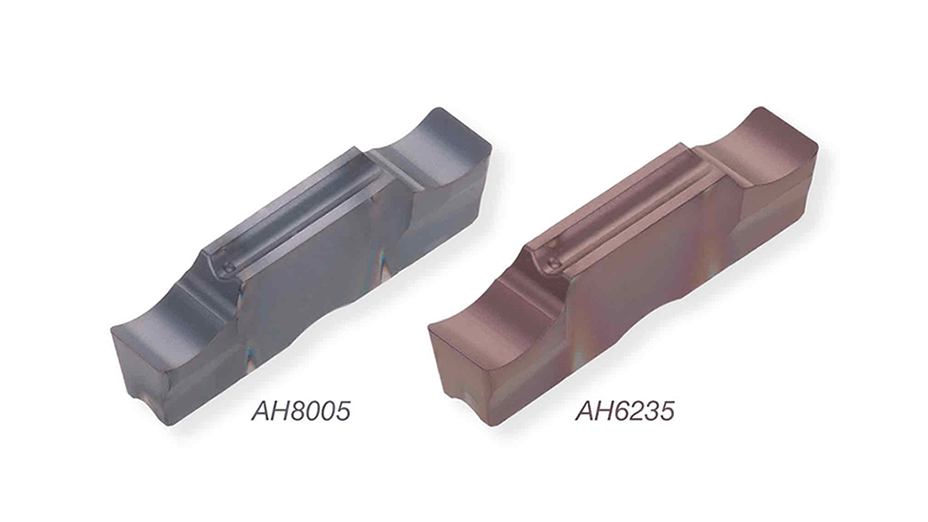

Značajka 1: AH8005 – Otporna na trošenje, idealna za brzu i kontinuiranu obradu

– Pogodna za širok raspon materijala obrade, uključujući toplinski otporne legure, nehrđajući čelik i općenito čelike

– Pokazuje izvrsnu otpornost na trošenje čak i pri visokim temperaturama što značajno produžuje vijek trajanja alata

– Pruža stabilne rezne performanse u kontinuiranim i visokobrzinskim operacijama obrade

Značajka 2: AH6235 – Žilava kvaliteta za prekinute rezove i teške uvjete obrade

– Konstruirana da se nosi s prekinutim rezovima i operacijama odrezivanja gdje su česti lomovi i odkrhnuća reznog brida

– Visoka žilavost smanjuje rizik od loma, omogućujući stabilnu obradu

– Nudi izvanrednu pouzdanost čak i pri obradi teško obradivih materijala poput nehrđajućeg čelika

Dodatkom ovih kvaliteta, TungCut se sada prilagođava širem rasponu uvjeta obrade i materijala obrade, doprinoseći poboljšanoj produktivnosti i smanjenju troškova u proizvodnim okruženjima.