Iwaki, Japan – January, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its SolidMeister series, featuring the new grade AH3005 for enhanced durability in machining high-hardness materials up to 65 HRC. The lineup now offers tool diameters from 0.3 to 6.0 mm, including versatile ball, 2-flute, 4-flute, and 6-flute square end mills, enabling high-efficiency machining and extended tool life across a wide range of applications.

Challenges and Trends

In the field of mold machining and high-hardness steel machining, numerous challenges related to tool life and machining efficiency are commonly observed. Particularly in the machining of high-hardness steel, tools experience severe wear, making it difficult to complete shape machining with a single end mill. Additionally, the conventional lineup of small-diameter end mills often falls short of meeting certain machining requirements, creating a demand for more options. Furthermore, even when using 4-flute end mills for finishing processes, machining efficiency does not sufficiently improve, making it challenging to maintain productivity. To address these challenges and market conditions, the development of higher-performance end mills capable of meeting diverse needs is strongly demanded by the market.

Product Overview

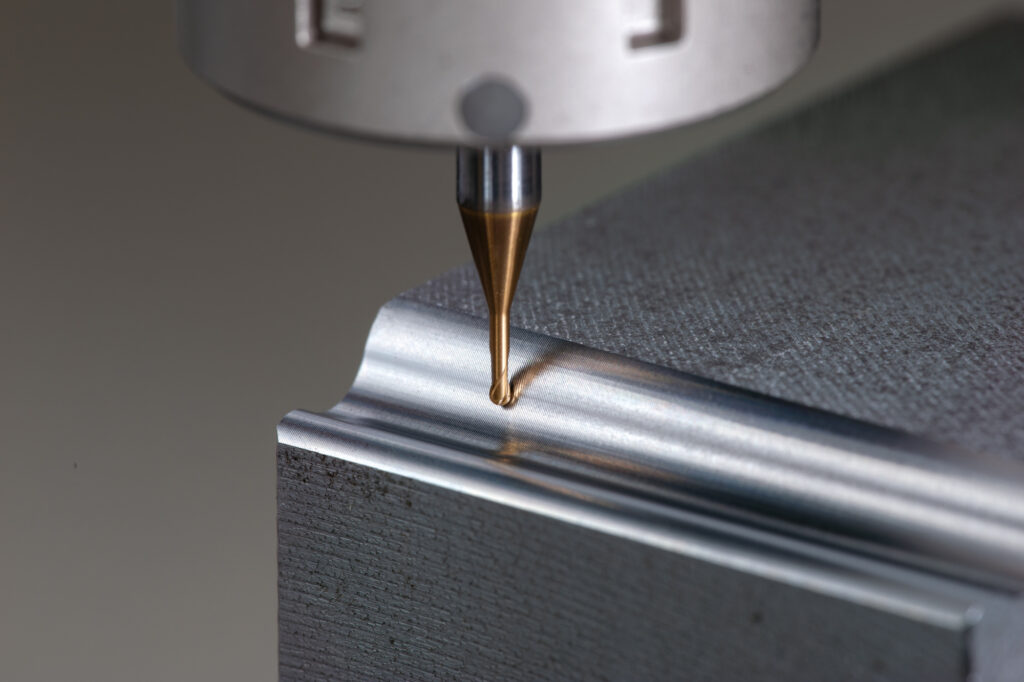

SolidMeister is a high-performance end mill ideal for precision-demanding fields such as mold machining, aerospace components, and turbine blades. It is designed to handle difficult-to-machine materials like steel, heat-resistant alloys, and titanium alloys. With cutting-edge technology, it delivers reduced machining time and enhanced productivity.

Benefits and Features

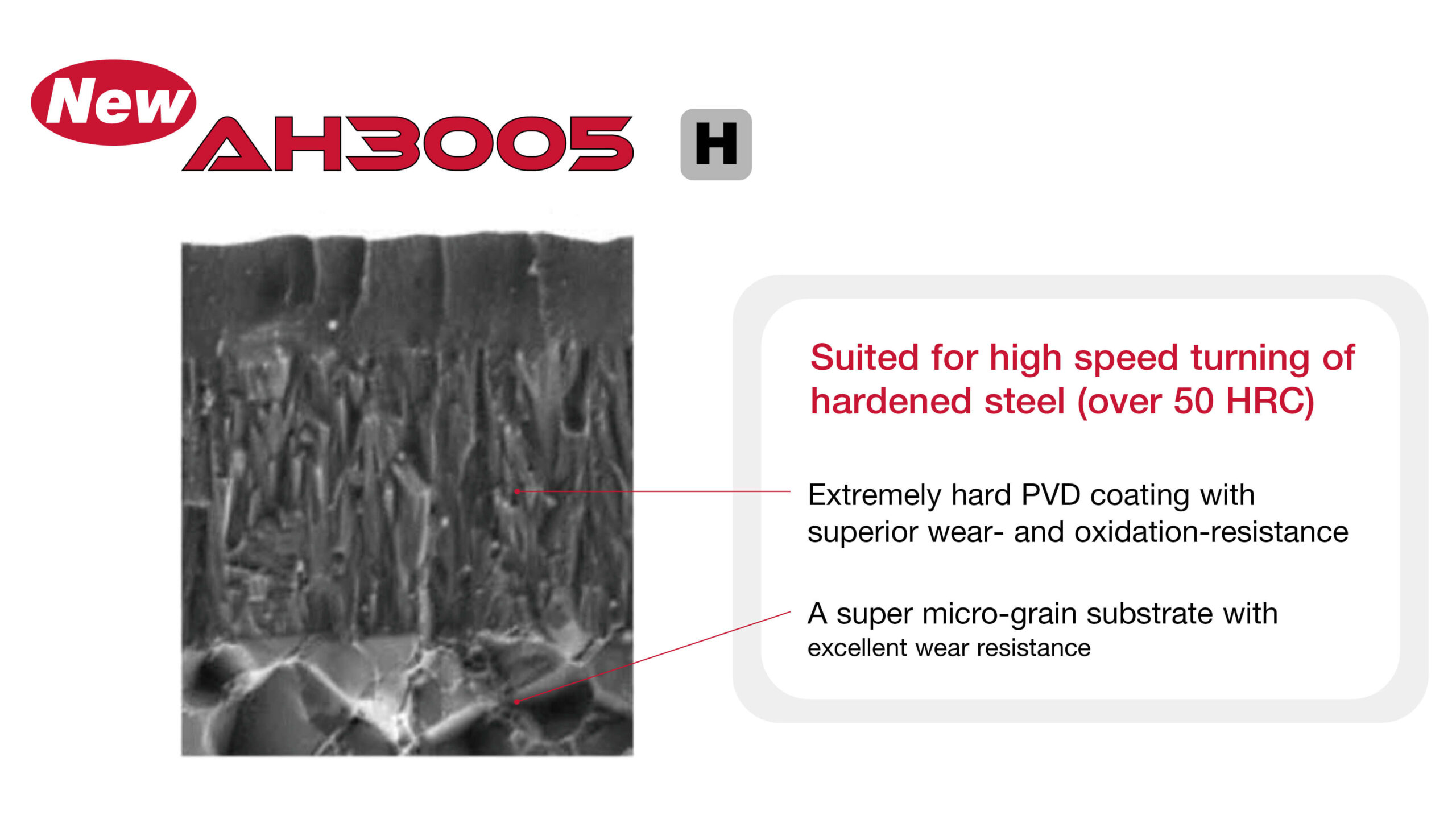

Feature 1: High-Hardness Material Compatibility with New Grade AH3005

Equipped with the new grade AH3005, capable of machining high-hardness materials up to 65 HRC.

Combination of a high-hardness substrate and a specialized coating significantly extends tool life.

Delivers stable machining performance, reducing machining costs.

Feature 2: Expanded Small-Diameter Lineup

Offers a wide range of tool diameters from 0.3 mm to 6.0 mm.

Adds 175 items, including ball-end mills and square-end mills, to meet diverse machining needs.

Exhibits high versatility for various applications, from micro machining to finishing.

Feature 3: High-Efficiency Machining with 6-Flute Square End Mills

Newly expanded lineup of 6-flute square end mills for tool diameters ranging from φ3-6 mm.

Increased number of cutting edges enhances machining efficiency and reduces machining time.

Combines high-efficiency machining with extended tool life, significantly boosting productivity.

Cutting Performance

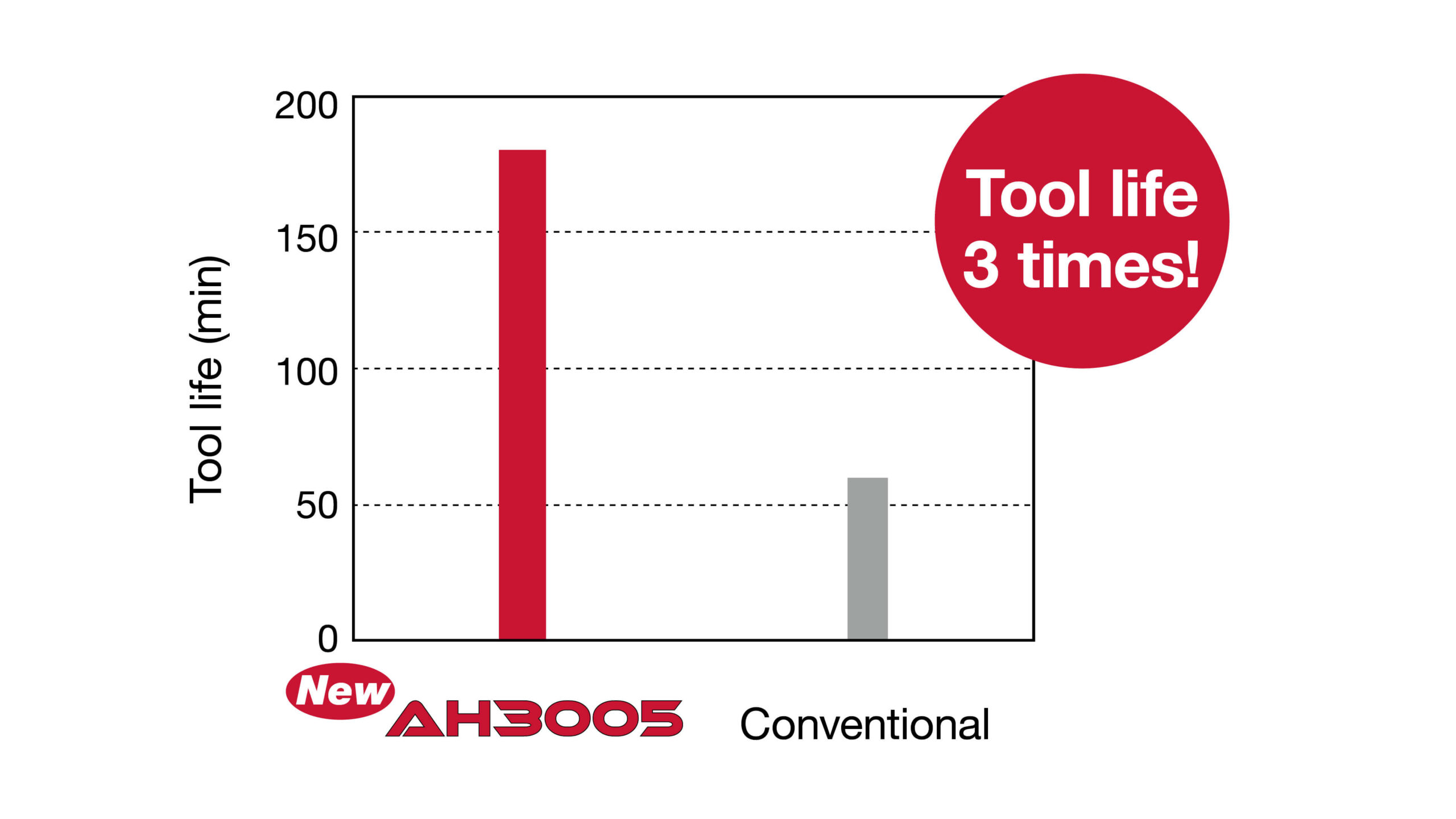

Tool Life Comparison

| Endmill | TEB030A2-040/08C6H-55 (ø3 mm, z = 2) |

| Workpiece material | SKD61 / X40CrMoV5-1 (50 HRC) |

| Cutting speed | Vc = 41 m/min |

| Feed per tooth | fz = 0.028 mm/t |

| Depth of cut | ap = 0.2 mm |

| Width of cut | ae = 1 mm |

| Coolant | Wet (External) |

AH3005 provided good wear resistance for hardned materials.