Iwaki, Japan – siječanj 2026. – Tungaloy Corporation (predsjednik: Satoshi Kinoshita, sjedište: Iwaki City, prefektura Fukushima) najavljuje proširenje svoje DS2000 serije s DLC premazom, optimizirane za obradu aluminija i obojenih metala, pružajući vrhunsku završnu obradu površine, produljeni vijek trajanja alata i povećanu produktivnost u operacijama tokarenja i glodanja.

Izazovi i trendovi

Posljednjih godina, trend prema laganom dizajnu i većoj učinkovitosti ubrzao se u širokom rasponu industrija, uključujući automobilsku, zrakoplovnu, poluvodičku, robotsku i industriju građevinskog materijala. Među njima, primjena aluminijskih legura i obojenih metala—poznatih po svojim laganim, ali vrlo čvrstim svojstvima—brzo se širi. Posljedično, potražnja za visoko preciznom i učinkovitom obradom ovih materijala raste.

Međutim, aluminij je sklon problemima kao što su stvaranje naslaga na oštrici i stvaranje srha tijekom rezanja, što otežava održavanje stabilnog vijeka trajanja alata i dosljedne kvalitete završne obrade površine. Na tržištu postoji snažna potreba za rješenjima za obradu koja mogu prevladati ove izazove uz postizanje produktivnosti i kvalitete.

Pregled proizvoda

ISO-insert

Application:

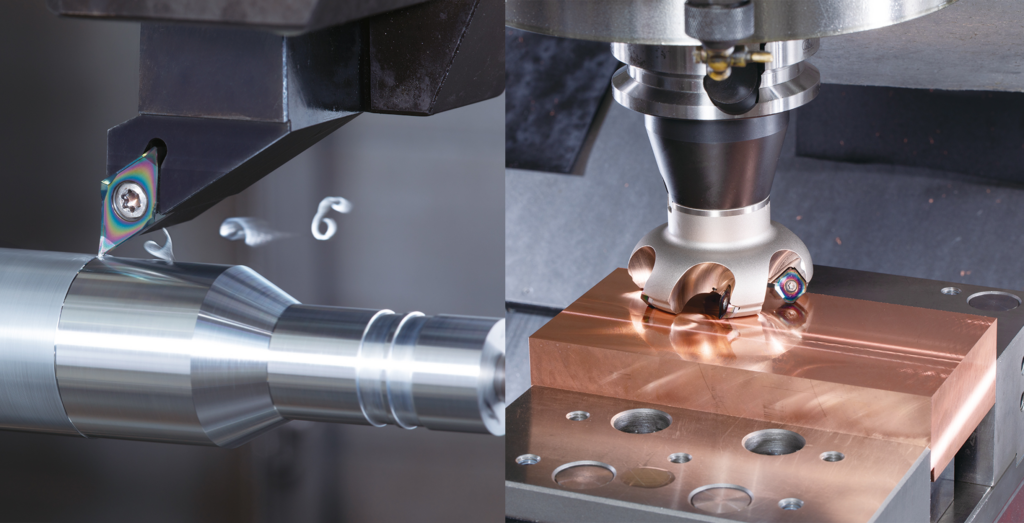

DLC-coated grade for non-ferrous metal ISO turning (e.g., external turning).

Features:

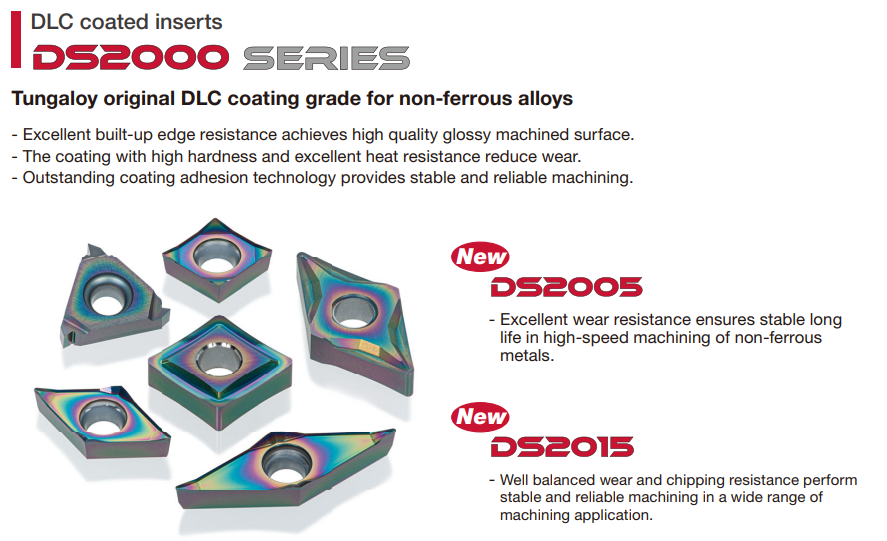

- Excellent built-up edge (BUE) / adhesion resistance, delivering a bright, high-quality surface finish.

- High hardness and heat resistance help suppress wear progression for stable, long tool life.

- Strong coating adhesion supports reliable and stable machining.

- Non-ferrous chipbreaker lineup: AL (positive) / 28 (negative) for improved chip control and reduced chip entanglement.

👉 Best suited when you want stable surface finish and longer tool life in non-ferrous turning, especially where adhesion/BUE is a concern.

TungThread

Application:

DLC-coated grade for non-ferrous threading (external/internal), partial-profile type.

Features:

- Enables high thread surface quality while significantly reducing adhesion/BUE on rake and flank faces, helping slow wear.

- Ground, high-precision inserts for consistent thread quality.

- 60° / 55° partial-profile supports both external and internal threads; applicable to ISO metric (M), UN, W, and G threads.

👉 Best suited when you want stable thread quality in non-ferrous materials, minimizing adhesion, surface issues, and rapid wear

TungForce-Rec

Application:

90° square shoulder milling cutter for stable, high-efficiency milling.

Features:

- Unique V-bottom insert and clamping mechanism for stable machining.

- High-rigidity body design and secure insert clamping help prevent insert movement.

- Designed to deliver stable performance even in small-diameter applications.

👉 Best when you want reliable, high-productivity square shoulder milling with strong process stability.

Tung-Tri

Application:

Square shoulder milling cutter focused on economy and chatter stability.

Features:

- Economical 3 cutting-edge insert with large rake angle reduces cutting force and improves chip formation.

- Optimized insert flank face and differential pitch on the cutter help suppress chatter.

- Large rake/inclination angles support smooth cutting while maintaining edge strength.

👉 Best when you want cost-efficient, stable shoulder milling with good cutting action.

TungAluMill

Application:

High-speed shoulder milling for aluminum and non-ferrous materials.

Features:

- Secure, stable insert clamping design with a unique V-shaped bottom for high-speed machining.

- Cutting edge geometry optimized for aluminum machining.

- Applicable to a wide range of operations (e.g., pocketing/slotting and helical ramping).

👉 Best when you want stable high-speed Al/non-ferrous milling with broad application coverage.

DoMultiRec

Application:

Multifunctional milling cutter with center-cutting capability (incl. drilling).

Features:

- Center cutting capability enables multiple operations with a single tool, including drilling.

- Insert integrates a center and peripheral cutting edge on one side.

- Double-sided insert allows up to four indexings (front/back; center/periphery positions).

👉 Best when you want to reduce tool changes and maximize versatility with one cutter.

TFE / EFE (TungMill / TFE12, EFE12)

Application:

High-precision face milling focused on surface finish and accuracy.

Features:

- Lightweight facemill body design for high-precision machining.

- Adjustable pockets for extra precision on surface finish.

- Insert pitch (density) variations to select the best balance of economy and productivity.

👉 Best for precision face milling where controlled surface finish is critical.

DoPent

Application:

High-speed face milling with superior surface finish (all materials).

Features:

- Economical double-sided pentagonal insert with 10 cutting edges.

- Low cutting force concept supports stable machining.

- Especially suitable for thin or low-rigidity workpieces thanks to reduced cutting/radial forces.

👉 Best when you want low cost per edge + stable, high-speed face milling with good finish.

TungMill

Application:

Milling solution for steel and cast iron (face/shoulder/chamfering).

Features:

- Simulation-based design provides a lightweight cutter with low cutting load while maintaining rigidity.

- TPW/EPW type features a 4-corner insert design balancing sharpness and edge strength.

- 45° and 90° cutting edge angle supports square shoulder milling and face milling around obstacles/fixtures.

👉 Best for steel/cast-iron milling where you want accuracy, efficiency, and stable cutting behavior.

Prednosti i značajke

Značajka 1: Postizanje visokokvalitetnih obrađenih površina kroz izvrsne performanse protiv prianjanja

- Novo razvijeni DLC premaz značajno suzbija prianjanje s aluminijem i obojenim metalima

- Sprječava stvaranje naslaga na oštrici, pružajući sjajne i vrlo precizne završne obrade površine

- Stabilna kvaliteta površine smanjuje potrebu za sekundarnim operacijama završne obrade

Značajka 2: Produljeni vijek trajanja alata kroz visoku tvrdoću i otpornost na toplinu

- Visoka tvrdoća DLC filma minimizira napredovanje trošenja ruba

- Izvrsna otpornost na toplinu osigurava stabilne performanse čak i pri brzom i visoko učinkovitom strojnom obrađivanju

- Smanjuje učestalost izmjene alata i doprinosi ukupnom smanjenju troškova

Značajka 3: Stabilne performanse za širok raspon primjena strojnog obrađivanja

- Snažna adhezija premaza pruža stabilne performanse rezanja u različitim operacijama kao što su tokarenje, urezivanje navoja i glodanje

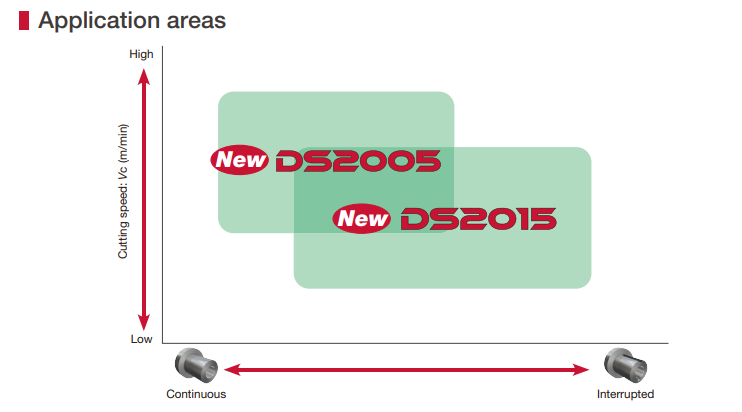

- Vrsta DS2005 poboljšava otpornost na trošenje za brzo strojno obrađivanje, postižući dulji vijek trajanja alata

- Vrsta DS2015 nudi izvrsnu ravnotežu otpornosti na trošenje i otpornosti na krhotine, omogućujući stabilno strojno obrađivanje u širokom rasponu uvjeta