Machining program compensation for wiper SW/FW insert

The nose radius on a wiper insert has a different configuration from that on standard ISO insert's. Machining program adjustments are, therefore, required to generate a correct offset for the wiper insert to machine the correct workpiece dimension. No compensation is needed, however, for the positive, CCMT-SW wiper insert.

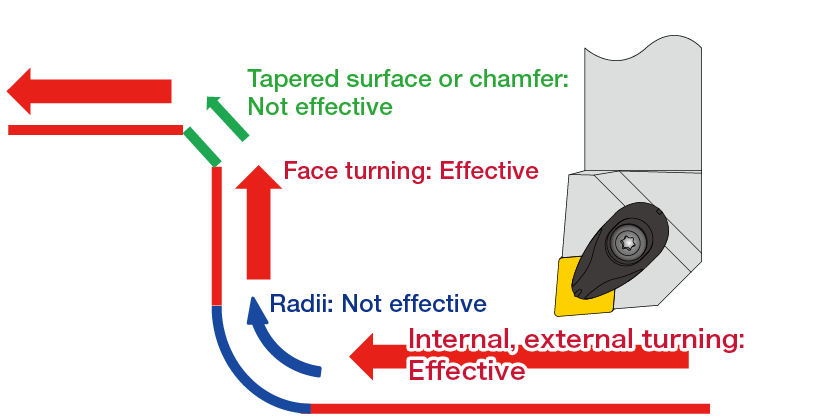

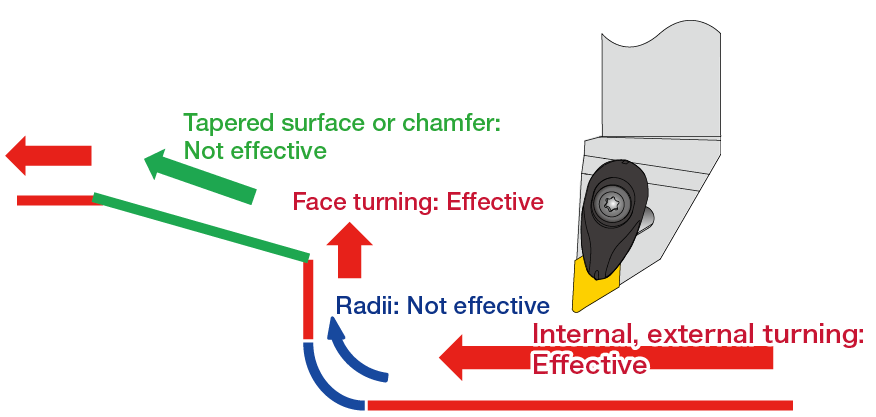

Wiper effectiveness (surface finish quality improvement) by applications

Additional information on offsetting -SW / -FW wiper inserts

Program compensations by insert shapes and applications

Match your insert shape and application to find the proper compensation method.

| Insert shape | |||

|---|---|---|---|

| CNMG/WNMG-SW/FW | DNMG/TNMG-SW/FW | CCMT-SW | |

| Applications | Type L | Type J, G, F | Type L |

|

Proceed to Compensation ① | Proceed to Compensation ④ | No compensation needed |

|

Proceed to Compensation ①,② | Proceed to Compensation ④,⑤ | ↑ |

|

Proceed to Compensation ①,③ | Proceed to Compensation ④,⑥ | ↑ |

|

Proceed to Compensation ①,②,③ | Proceed to Compensation ④,⑤,⑥ | ↑ |