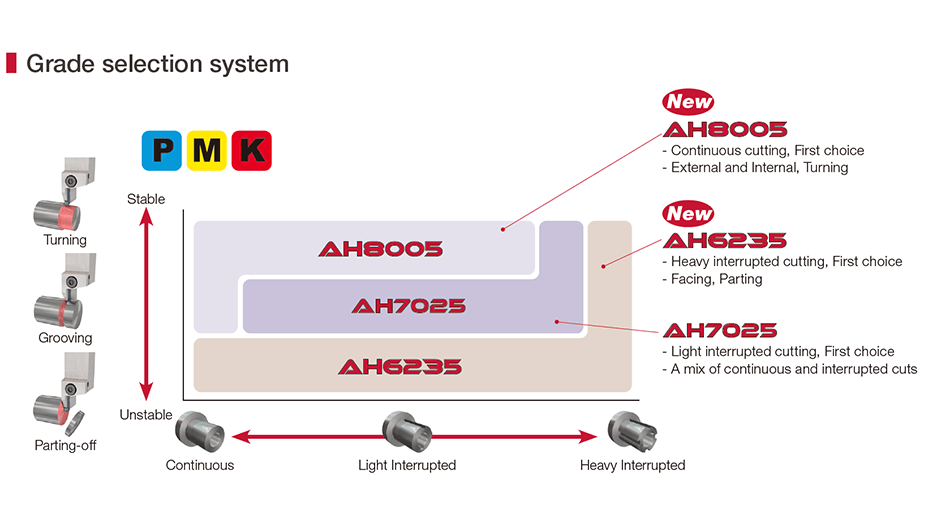

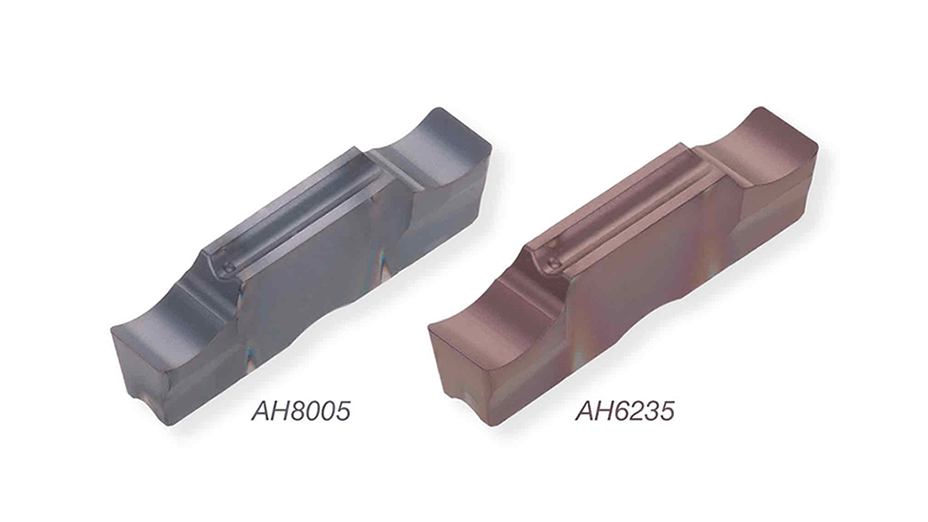

Iwaki, Japón – Noviembre de 2025 – Tungaloy Corporation (Presidente: Satoshi Kinoshita; Oficina central: Iwaki City, Prefectura de Fukushima) anuncia la ampliación de su serie TungCut con la introducción de dos nuevas calidades: la AH8005, de alta resistencia al desgaste, y la AH6235, de alta resistencia a la fractura.

Retos y tendencias

Las operaciones de ranurado y tronzado son fundamentales en la fabricación de maquinaria industrial y componentes para automoción. Sin embargo, estas operaciones a menudo implican condiciones de corte exigentes, como perfiles intermitentes o voladizos largos, que pueden generar problemas en la vida útil de la herramienta y la estabilidad del mecanizado.

En el mercado actual, donde la productividad y la optimización de costes son esenciales, resulta clave seguir mejorando el rendimiento de las herramientas. Para responder a estas exigencias, se espera con gran interés la incorporación de nuevas calidades de herramienta de corte que ofrezcan una mayor vida útil y un mecanizado estable.

Descripción general del producto

TungCut es una herramienta de ranurado y tronzado con un excelente control de la viruta y una estructura de sujeción muy rígida. Logra un acabado de alta calidad y es adecuada para una amplia gama de mecanizados. Combina una precisión estable con una larga vida útil de la herramienta.

Ventajas y características

Característica 1: AH8005 – Calidad resistente al desgaste ideal para el mecanizado continuo y a alta velocidad

– Adecuada para una amplia gama de materiales de la pieza de trabajo, incluidas las aleaciones resistentes al calor, el acero inoxidable y el acero general

– Exhibe una excelente resistencia al desgaste incluso a altas temperaturas, lo que prolonga significativamente la vida útil de la herramienta

– Ofrece un rendimiento de corte estable en operaciones de mecanizado continuo y a alta velocidad

Característica 2: AH6235 – Calidad resistente para el corte interrumpido y de alta exigencia

– Diseñadas para afrontar cortes interrumpidos y operaciones de tronzado en las que son habituales el astillado y la rotura.

– Su alta tenacidad reduce el riesgo de fallo de la herramienta, permitiendo un mecanizado estable.

– Ofrece una fiabilidad excepcional incluso al mecanizar materiales difíciles de cortar, como el acero inoxidable

Con la adición de estas calidades, TungCut ahora puede adaptarse a una gama más amplia de condiciones de mecanizado y materiales de la pieza de trabajo, lo que contribuye a mejorar la productividad y reducir los costes en entornos de fabricación.