Una nueva generación de fresas para aplicaciones a alto avance con gran versatilidad

El diseño único de la plaquita permite cambiar los ángulos de entrada

Se puede seleccionar la profundidad de corte optima al mecanizar varios tipos de materiales

Aplicaciones y características

Aplicaciónes

Características

1. 2 Tipos de plaquita pueden adaptarse a la misma fresa proporcionando dos ángulos de entrada diferentes

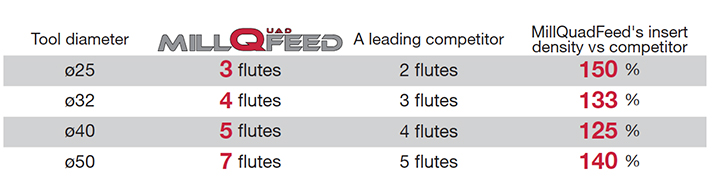

2. Diseño de paso estrecho para una alta eficiencia

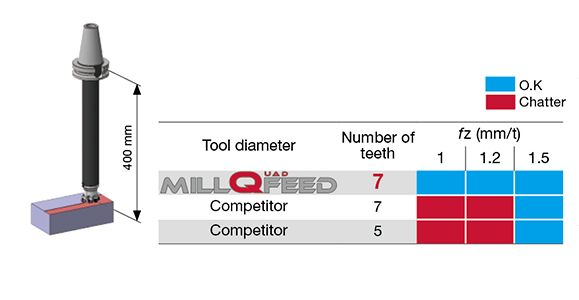

3. Estabilidad de las vibraciones superior

Plaquitas y calidad

Plaquitas

SWMT09/15**ZER

- Máx. profundidad de corte

– SWMT09**ZER: 1,5 mm

– SWMT15**ZER: 2,5 mm - Plaquita con mayor ángulo de corte en la fresa

SWMT09/15**UER

- Máx. profundidad del corte

– SWMT09**UER: 1mm

– SWMT15**UER: 2mm - Plaquita con menor ángulo de corte en la fresa

- Efecto de adelgazamiento de viruta ideal para mecanizar acero inoxidable y otros materiales difíciles de cortar

- Minimiza la vibración en voladizos largos

SWMW**ZSR/USR

-

- Max. depth of cut

– SWMW0904ZSR: 1.5 mm

– SWMW0904USR: 1 mm

– SWMW1506USR: 2 mm

- Max. depth of cut

Calidades principales

AH8015

![]()

![]()

![]()

![]()

![]()

- Buen equilibrio entre resistencia al desgaste y a la rotura

- Primera opción para mecanizar aleaciones resistentes al calor en condiciones de corte estándar

AH3225

![]()

![]()

- Buen equilibrio entre resistencia al desgaste y a la rotura

- Adecuado para acero y acero inoxidable.

AH120

![]()

![]()

![]()

![]()

- Buen equilibrio entre resistencia al desgaste y a la rotura

- Adecuado para mecanizar acero, acero inoxidable y hierro fundido en condiciones de corte estándar

Cuerpos de fresa

Tipo modular

HXSW09 (ø22 – ø32 mm)

Cabezal modular (TungFlex) para fresado de radios o para aplicaciones a alto avance

Tipo vaso

TXSW09/15 (ø40 – ø160 mm)

Tipo vaso para fresado de radio o para aplicaciones a alto avance

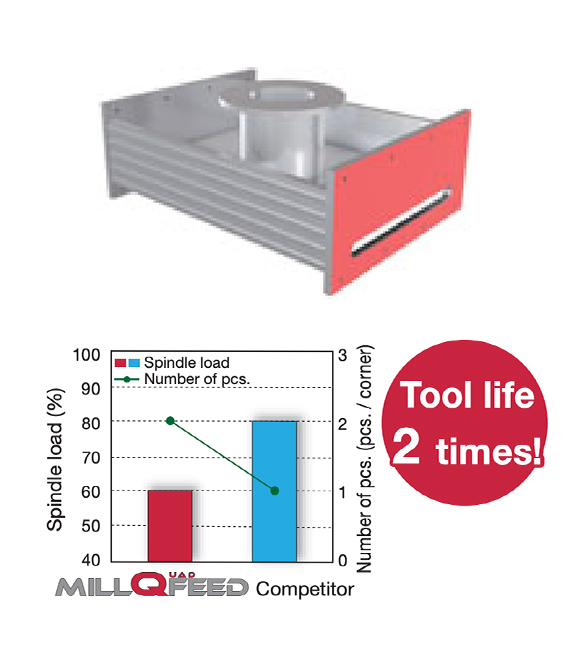

Ejemplos prácticos

Ejemplo #1

Industria aeroespacial

| Pieza: | Parte del cojinete del extremo de la barra |

| Material: | 17-4PH (PH acero inoxidable, 38HRC) |

| Fresa: | EXSW09M032C32.0R04 (ø32, z=4) |

| Plaquita: | SWMT0904UER-MM |

| Calidad: | AH3135 |

| Condiciones de corte: | Vc = 200 (m/min) fz = 0.75 (mm/t) ap = 0.6 (mm) ae = 13 (mm) Aplicación: Fresado frontal Refrigerante: Taladrina Máquina: máquina multitarea |

Ejemplo #2

Ingeniería general

| Pieza: | Mandril magnético |

| Material: | SS400 / E275A |

| Fresa: | EXSW09M025C25.0R03 (ø25, z=3) |

| Plaquitas: | SWMT0904UER-MM |

| Calidad: | AH3135 |

| Condiciones de corte: | Vc = 274 (m/min) fz = 0.83 (mm/t) ap = 0.7 (mm) ae = 25 (mm) Aplicación: Ranurado Refrigerante: Taladrina Máquina: Horizontal M/C, BT50 |

Ejemplo #3

Ingeniería general

| Pieza: | Cámara |

| Material: | SUS304 / X5CrNi18-9 |

| Fresa: | TXSW15J160B50.8R08 (ø160, z=8) |

| Plaquita: | SWMT1506ZER-MM |

| Calidad: | AH3135 |

| Condiciones de corte: | Vc = 150 (m/min) fz = 1 (mm/t) ap = 1 (mm) ae = 130 (mm) Aplicación: Refrentado Refrigerante: Seco Máquina: M/C horizontal, BT50, 22kW |

Condiciones de corte estándar

09 type

| ISO | Workpiece material | Hardness | Priority | Insert type | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|---|

| Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 300 | 0.5 – 1.5 | ||||

| Wear resistance | UER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Alloy steel SCM440, etc. 42CrMo4, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.5 | ||||

| Wear resistance | UER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.2 | ||||

| Wear resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.2 | ||||

| Austenitic stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200HB | First choice | UER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||

| Fracture resistance | UER | AH130 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Low cutting force | ZER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Precipitation hardening stainless steel SUS630, etc. X20CrNiCuNb-16-4, etc. |

28HRC – (H1150) |

First choice | UER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||

| Fracture resistance | UER | AH130 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| Low cutting force | ZER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| 40HRC – (H900) |

First choice | UER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | |||

| Fracture resistance | UER | AH130 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Low cutting force | ZER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Gray cast iron FC250, FC300, etc., 250, 300, etc. |

150 – 250HB | First choice | ZSR | AH8015 | Flat top | 100 – 300 | 0.5 – 2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Ductile cast iron FCD600, etc., 600-3, etc. |

150 – 250HB | First choice | ZSR | AH8015 | Flat top | 80 – 200 | 0.5 – 2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 80 – 200 | 0.5 – 2 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40HRC | First choice | UER | AH130 | MM | 30 – 60 | 0.3 – 0.7 | ||

| Wear resistance | UER | AH8015 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Low cutting force | ZER | AH130 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Heat-resistant alloys Inconel, Hastelloy, etc. |

– 40HRC | First choice | UER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||

| Fracture resistance | USR | AH8015 | Flat top | 20 – 50 | 0.1 – 0.3 | ||||

| Low cutting force | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | USR | AH8015 | Flat top | 80 – 130 | 0.1 – 0.3 | |

| Fracture resistance | USR | AH3225 | Flat top | 80 – 130 | 0.1 – 0.3 | ||||

| Low cutting force | ZSR | AH8015 | Flat top | 80 – 130 | 0.1 – 0.3 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | USR | AH8015 | Flat top | 50 – 70 | 0.05 – 0.2 | ||

15 type

| ISO | Workpiece material | Hardness | Priority | Insert type | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|---|

| Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Alloy steel SCM440, etc. 42CrMo4, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 200 | 0.5 – 1.5 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 2 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 200 | 0.5 – 1.2 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.5 | ||||

| Austenitic stainless steel SUS304, etc., X5CrNi18-9, etc. |

– 200HB | First choice | UER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||

| Low cutting force | ZER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Precipitation hardening stainless steel SUS630, etc. X20CrNiCuNb-16-4, etc. |

28HRC – (H1150) |

First choice | UER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||

| Low cutting force | ZER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| 40HRC – (H900) |

First choice | UER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | |||

| Low cutting force | ZER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Gray cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | ZER | AH8015 | MT | 100 – 300 | 0.5 – 2 | ||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Low cutting force | ZER | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 250HB | First choice | ZER | AH8015 | MT | 80 – 200 | 0.5 – 2 | ||

| Fracture resistance | USR | AH3225 | Flat top | 80 – 200 | 0.5 – 2 | ||||

| Low cutting force | ZER | AH8015 | MM | 80 – 200 | 0.5 – 1.5 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40HRC | First choice | UER | AH3135 | MM | 30 – 60 | 0.3 – 0.7 | ||

| Low cutting force | ZER | AH3135 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 30 – 60 | 0.3 – 0.7 | ||||

| Heat-resistant alloys Inconel, Hastelloy, etc. |

– 40HRC | First choice | UER | AH3135 | MM | 20 – 50 | 0.1 – 0.3 | ||

| Wear resistance | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | USR | AH3225 | Flat top | 80 – 130 | 0.1 – 0.3 | |

| Wear resistance | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | USR | AH8015 | Flat top | 50 – 70 | 0.05 – 0.2 | ||

Para obtener más información sobre este producto, visite nuestro catálogo en línea o descargue el informe del producto: