PVD grade for heat-resistant alloys

Maximize productivity in superalloys machining

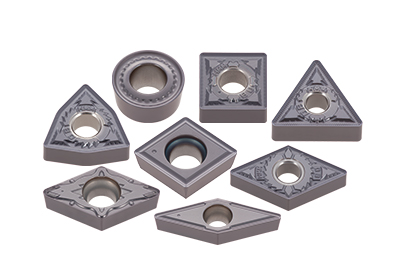

Applications & Features

Applications

Features

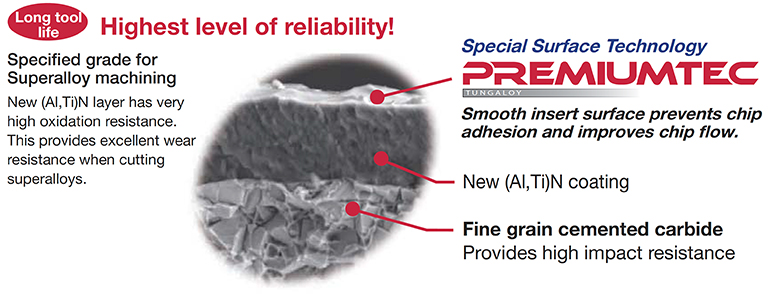

1. Highest level of reliability

Grades

Practical examples

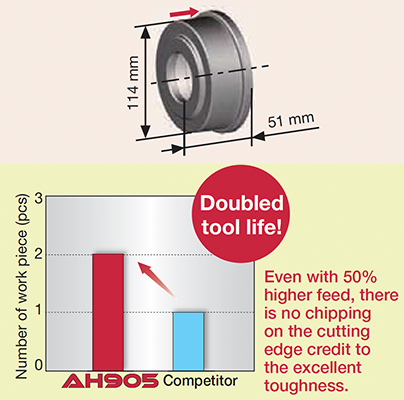

Exemple #1

Aerospace Industry

| Part: | Engine component |

| Material: | Inconel 718 |

| Insert: | CNMG120408-HMM AH905 |

| Cutting conditions: | Vc = 45 (m/min) f = 0.25 (mm/rev) ap = 1.0 (mm) Coolant: Wet |

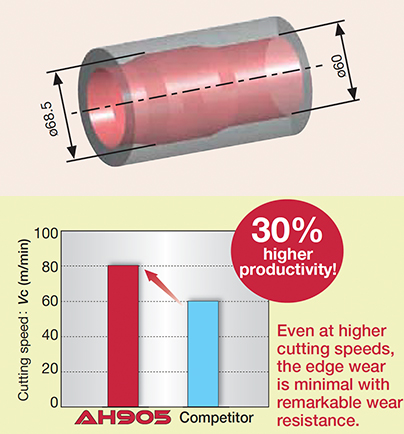

Exemple #2

Aerospace Industry

| Part: | Aerospace component |

| Material: | High strength steel alloy |

| Insert: | DCMT11T308-PSF AH905 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.1~0.15 (mm/rev) ap = 1.5~2.0 (mm) Coolant: Wet |

Standard cutting conditions

Negative inserts

| Work material | Application | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

f (mm/rev) Feed |

|---|---|---|---|---|---|---|

| Ni-base alloys Ni-base alloys (Inconel 718 etc) |

Medium cutting | HMM | AH905 | 20 – 100 | 0.5 – 3.0 | 0.1 – 0.3 |

Positive inserts

| Work material | Application | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

f (mm/rev) Feed |

|---|---|---|---|---|---|---|

| Ni-base alloys Ni-base alloys (Inconel 718 etc) |

Finishing | PSF | AH905 | 20 – 100 | 0.05 – 0.5 | 0.02 – 0.3 |

| Finishing to light cutting |

PSS | 0.5 – 2.0 | 0.02 – 0.3 | |||

| Finishing to medium cutting |

PS | 0.5 – 2.5 | 0.02 – 0.3 | |||

| Medium cutting | All-round | 0.5 – 3.0 | 0.08 – 0.3 | |||

| Finishing to light cutting |

RS | 0.5 – 1.5 | 0.03 – 0.3 | |||

| Medium cutting | 61 | 0.5 – 2.0 | 0.2 – 0.6 |

For more information about this product, visit our online e-catalog or download the product report: