Iwaki, Japan – June, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DrillMeister series with the addition of the DMM drill head, designed specifically for machining stainless steels and exotic materials used in corrosion-resistant applications.

Challenges and Trends

Corrosion-resistant components such as fluid valves, fittings, semiconductor manufacturing parts, power generation equipment, and heat exchangers often require materials like stainless steel and other exotic materials. These materials tend to cause rapid tool wear, leading to increased tooling costs—one of the major concerns in production. Additionally, poor chip evacuation has been another challenge, negatively impacting both machining efficiency and tool life. There is a strong demand for products that can address these issues.

Product Overview

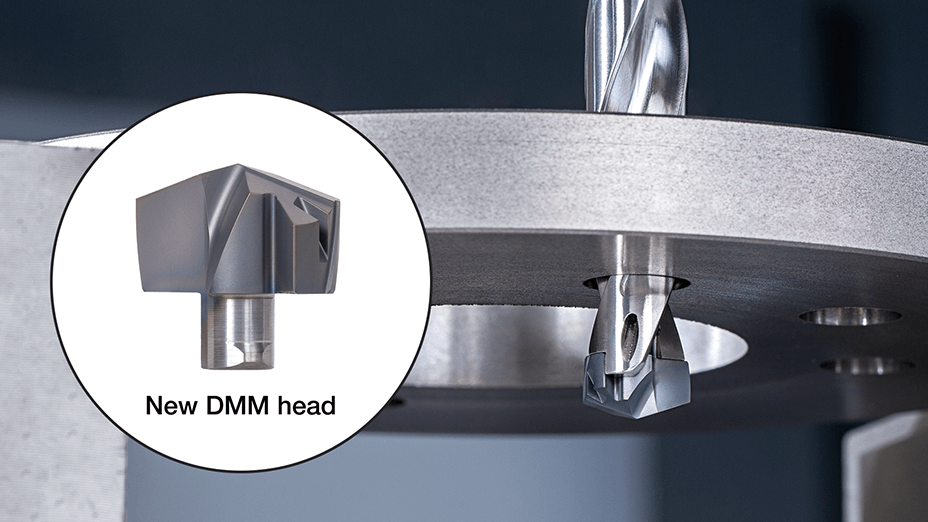

DrillMeister is a high-performance exchangeable-head drill. Its one-action head replacement allows users to maintain a consistently sharp cutting edge. With a highly precise clamping mechanism, it ensures stable hole-making operations and extended tool life. Newly introduced DMM drill head is specifically designed for stainless steel and exotic materials, offering longer tool life. Combined with the productivity benefits of the exchangeable-head system, the DMM head delivers outstanding cost performance.

Benefits and Features

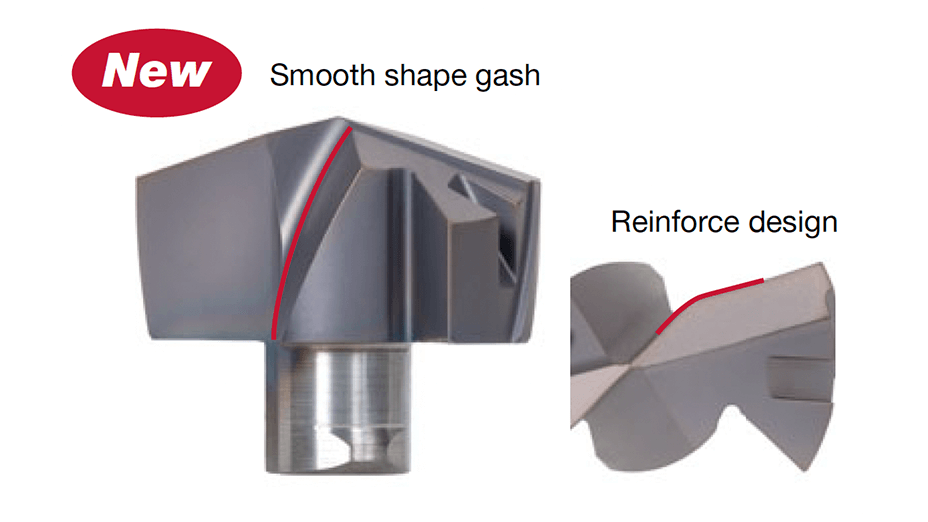

Unique gash geometry provides excellent chip control performance dedicate to stainless steel and exotic martials

・Effectively breaks chips even in stainless steel and difficult-to-cut materials known for long, stringy chips

・Improved chip evacuation leads to higher machining efficiency

Wide thinning pocket reduces cutting edge load

・Minimizes cutting edge stress during chip generation, extending tool life

・Enhances drilling stability during tool engagement

Compatible with existing DrillMeister bodies without modification

・No additional modifications needed—can be used with current setups

・Easy tool replacement helps reduce setup time

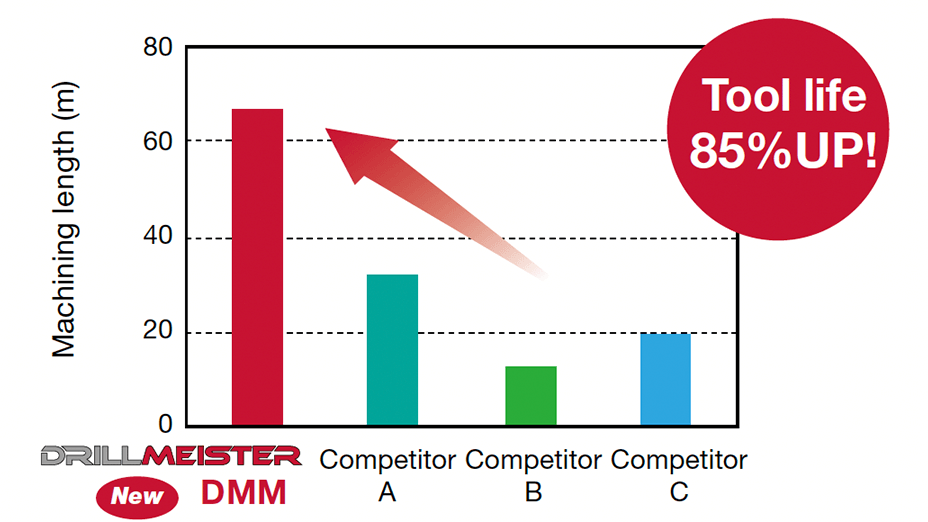

Cutting Performance

Tool Life Comparison

| Tool | ø14 mm, L/D = 5 |

| Drill head | DMM140 |

| Grade | AH9130 |

| Workpiece material | SUS304 / X5CrNi18-9 |

| Cutting speed | Vc = 60 m/min |

| Feed | f = 0.18 mm/rev |

| Hole depth | H = 50 mm |

| Coolant | Wet (Internal) |

| Tool | ø12 mm, L/D = 5 |

| Drill head | DMM120 |

| Grade | AH9130 |

| Workpiece material | Ni base alloy |

| Cutting speed | Vc = 23 m/min |

| Feed | f = 0.1 mm/rev |

| Hole depth | H = 12 mm |

| Coolant | Wet (Internal) |

| Machine | lathe |

Success Stories

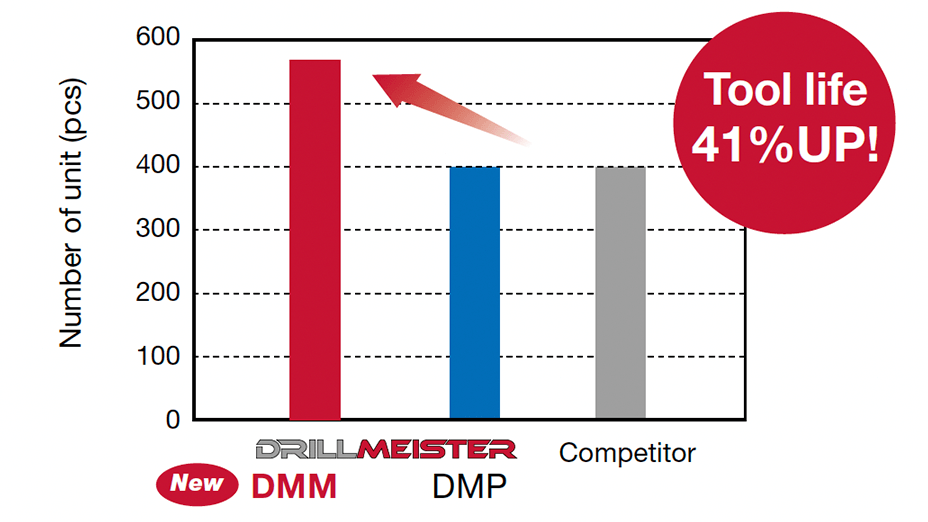

IMPROVED TOOL LIFE

Higher productivity:

-DrillMeister provides 1.3 times higher productivity due to higher feed rate .

Longer tool life

-Tool life is 1.3 times longer than competitor’s.

| Industry | Oil & Gas |

| Component | Ball Valve |

| Material ISO code | M – Stainless steel |

| Work material | SUS304 |

| Machine(Spindletype) | Vertical Machining Center |

| Tool family | Holemaking |

| Toolcategory | Drilling |

| Product name | DrillMeister |

| TSR No. | 5265D |