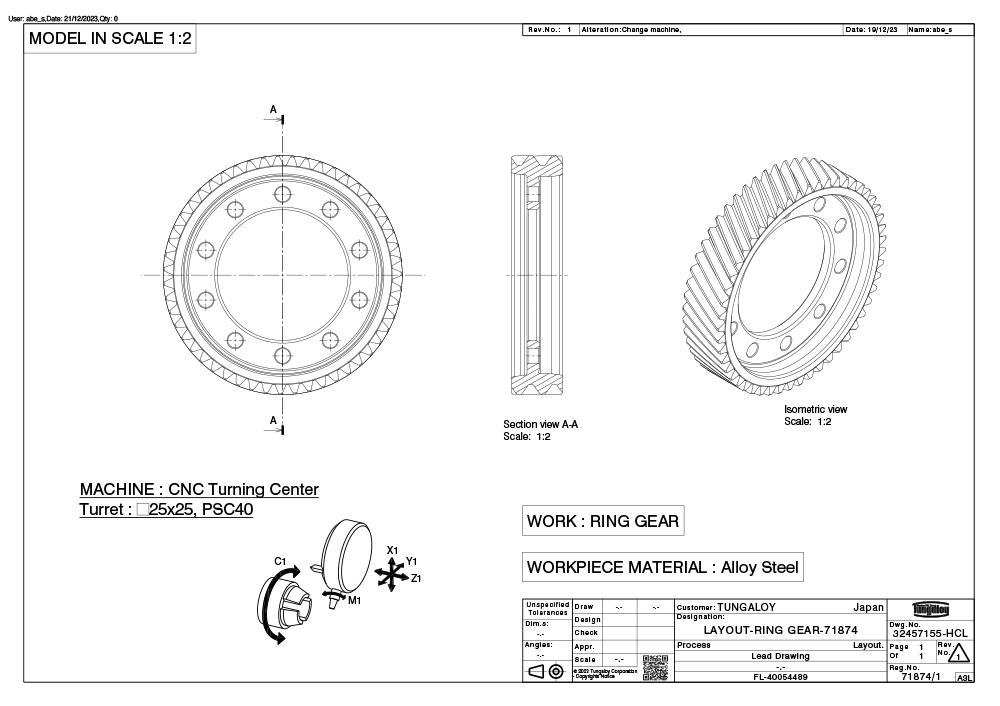

Automotive – Ring Gear

The ring gear of automotive components is an essential part for transmitting power in mechanical systems such as vehicle transmissions and differentials. Ring gears require high durability and strength as automobiles are used in various environments and under different loads, necessitating them to withstand long-term usage. Therefore, they are typically made from high-strength materials like alloy steel.

Tungaloy offers comprehensive cutting solutions to improve machining efficiency and quality even in the processing of high-strength materials, where machining difficulty increases.

Tooling concepts

- Achieving stable long life through materials with excellent wear resistance and resistance to damage

- Process consolidation with chamfered edge composite drills

- Improve machining efficiency and lower production costs by applying hard turning in post-hardening processes, eliminating the need for grinding

Featured process

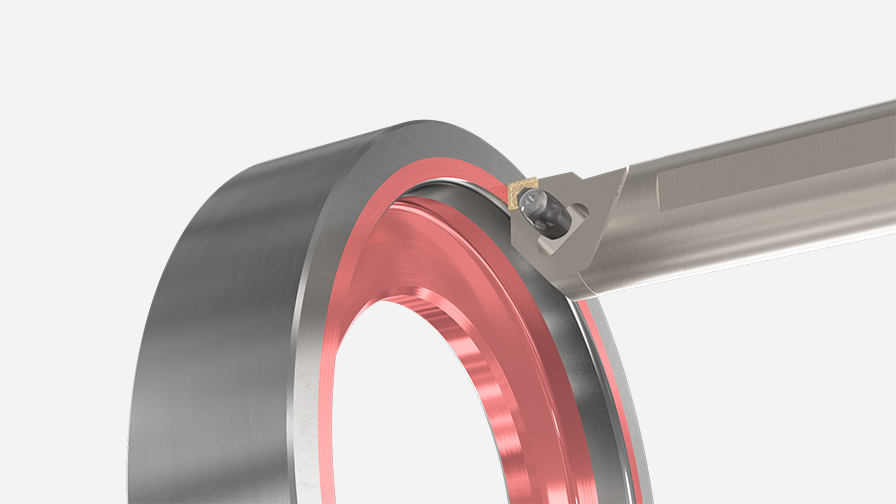

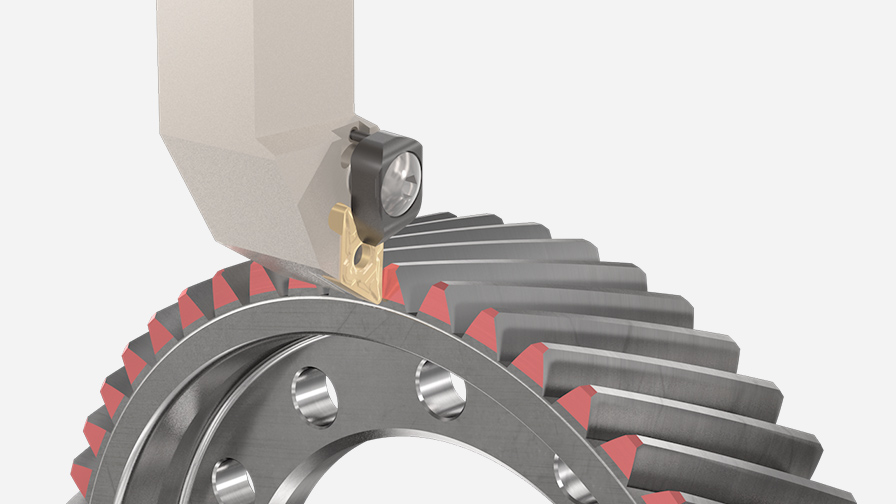

Process 1: Finish internal/face turning

Benefits

- Introducing the “A-type holder” with excellent operability and insert clamping rigidity to stabilize the cutting performance of inserts

- ISO-ECO TRN:Economical and environmentally friendly inserts that are smaller than standard inserts, reducing resource usage

- Ensuring equivalent performance to standard sizes while being smaller in size

- The ZM chip breaker exhibits excellent chip control not only during general machining but also during radius machining

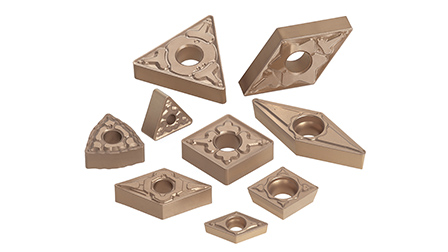

![]()

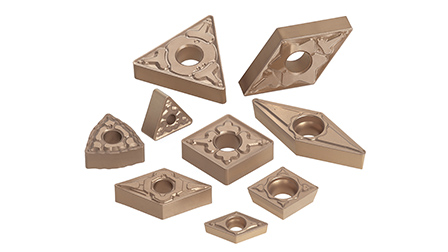

- A unique tough coating treatment technology that prevents cracks in operation and provides stable machining

- Latest CVD coating layer provides excellent wear resistance and excellent fracture resistance

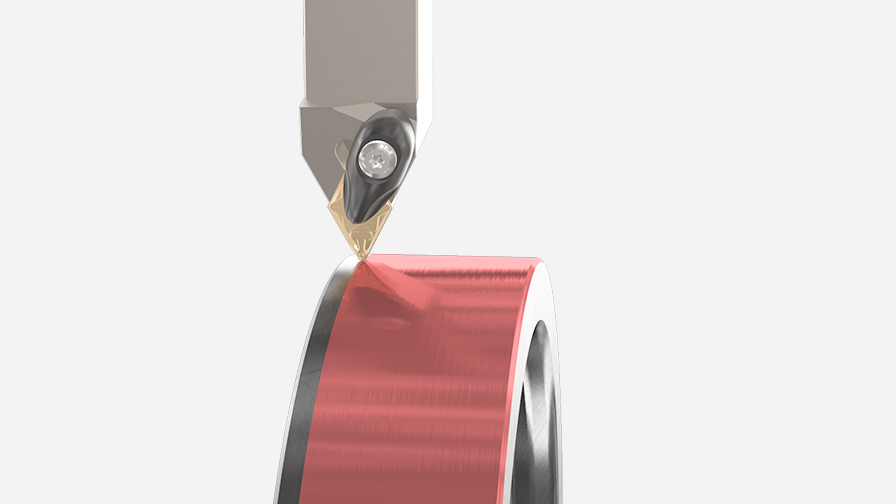

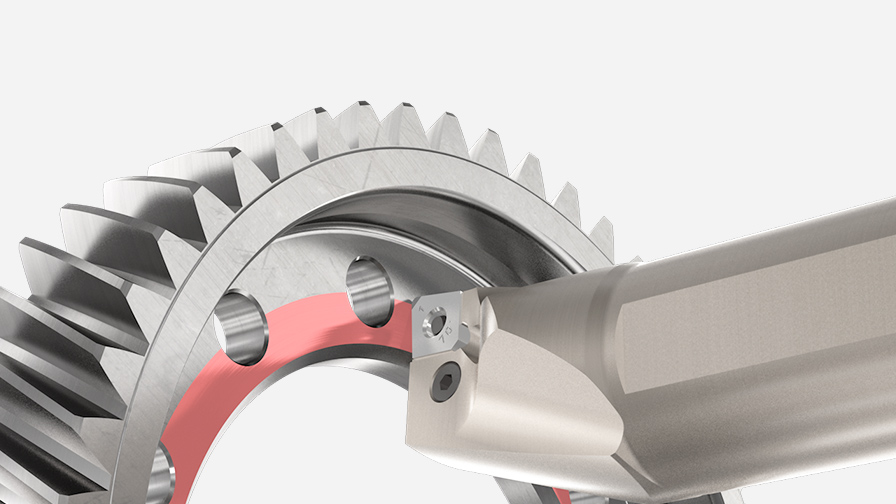

Process 2: Finish external turning

Benefits

- With a single screw tightening action, double clamping for both pull-in and pushing is possible, achieving excellent cutting edge stability with high clamping strength

- Increasing clamping force through expanded contact surfaces suppresses blade vibration, enhancing reliability

![]()

- A unique tough coating treatment technology that prevents cracks in operation and provides stable machining

- Latest CVD coating layer provides excellent wear resistance and excellent fracture resistance

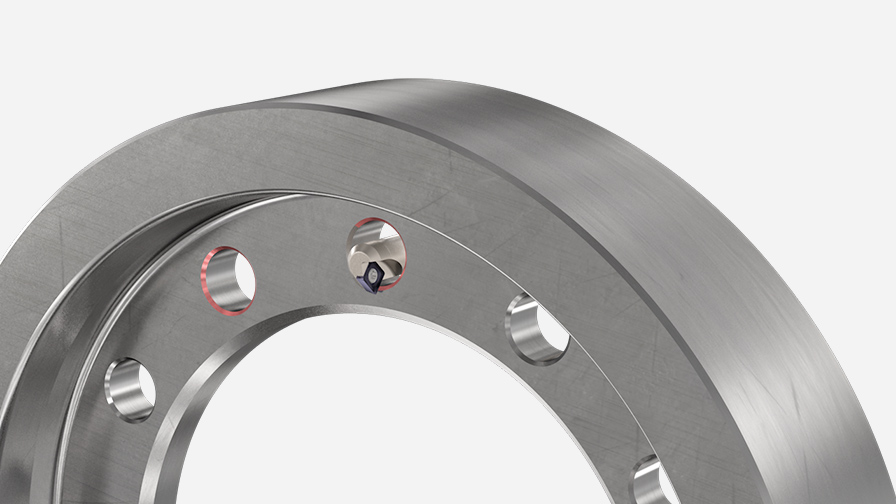

Process 3: Combination drilling with chamfering

Benefits

- Combined drilling and with chamfering using a DrillMeister head

- Achieving process reduction through simultaneous drilling and chamfering

- The drill head enables easy and quick head exchange through its unique self-locking clamp system

- The drill head provides stable long life without the need for regrinding or recoating, making it ideal for improving machining costs

DMP drill head

- Low resistance with sharp R-honing

- The latest AH9130 grade exhibits outstanding wear resistance in hole drilling, achieving stable long life

Process 5: Finish face turning

Benefits

- Achieving stable machining by securely clamping the insert from two directions, improving resistance to damage

- Easy insert replacement with single-operation capability

- The double-clamping mechanism ensures stable performance even during heavy interrupted cuts, realizing high productivity and machining quality

- The adoption of the TSF breaker enables excellent chip control and low resistance in finishing operations

![]()

- A unique tough coating treatment technology that prevents cracks in operation and provides stable machining

- Latest CVD coating layer provides excellent wear resistance and excellent fracture resistance

Process 6: Finish face turning (Hard turning)

Benefits

- Excelling in chip evacuation to suppress tool and workpiece damage caused by chip jamming or entanglement

- Designed to bring oil holes as close as possible to the tool edge to accurately supply cutting oil, thus suppressing flank wear and edge recession, achieving long life

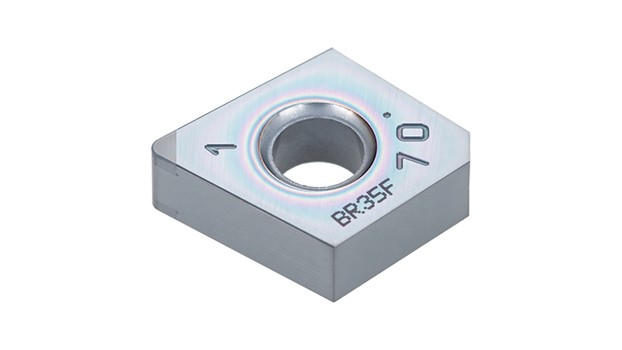

- BR35F is the first choice grade for heavy interrupted cuts, providing excellent resistance to damage in quenched and tempered steel machining

![]()

GNGA inserts

- Improved chip evacuation and machining surface quality by increasing the clearance between cutting edge and workpiece

- Chip biting is suppressed when machining end faces and when machining close to the edge of the face

- Compatible with ISO standard holders