Shoulder mill that enables high speed machining of aluminum and non-ferrous materials

V-shaped bottom secures insert on the cutter and supports high speed machining as well as helical ramping

Applications & Features

Applications

Features

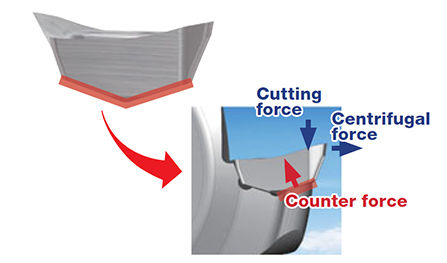

1. Secure, stable insert clamping design with unique V-shaped bottom

V shape provides counter force against the cutting force and centrifugal force.

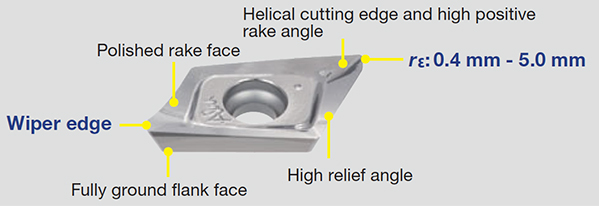

2. Excellent cutting edge geometry for aluminum machining

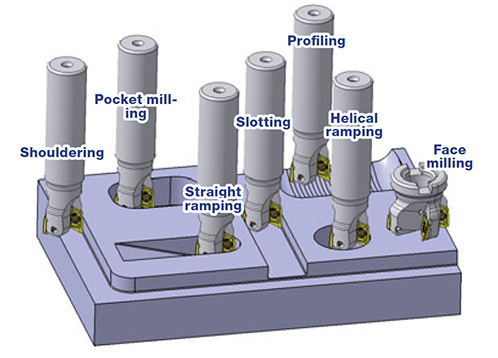

3. Applicable for a wide range of machining

Inserts & Grades

Inserts

XVCT16-AM

- Maximum depth of cut: 16 mm (It depends on corner radius)

- Sharp edges with polished rake surfaces for Aluminum alloy

Grades

Cutter bodies

Practical examples

Example #1

Aerospace Industry

| Part: | Airplane part |

| Material: | A7050 / AlZn5.5MgCu |

| Cutter: | EPXV16M032C32.0R03 (DC = 32 mm, CICT = 3) |

| Insert: | XVCT160530PEFR-AM |

| Grade: | TH10 |

| Cutting conditions: | Vc = 950 (m/min) fz = 0.14 (mm/t) ap = 2.5 (mm) ae = 18 (mm) Application: Pocketing Coolant: Wet Machine: Vertical M/C, BT50 |

Standard cutting conditions

| ISO | Workpiece material | Hardness (HB) |

Grade | Chip breaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

Tool dia: Dc (mm), Number of revolutions: n (min-1), Feed speed: Vf (mm/min), Depth of cut: ap = 2.0 mm, Number of inserts: CICT | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ø25 | ø32 | ø40 | ø50 | ø63 | ø80 | ø100 | ø125 | |||||||||||||||

| CICT = 2 | CICT = 3 | CICT = 3 | CICT = 4 | CICT = 5 | CICT = 5 | CICT = 6 | CICT = 7 | |||||||||||||||

| n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | n | Vf | |||||||

| Aluminium alloy | 60 | DS2015, TH10 | AM | 300 – 3000 | 0.15 – 0.35 | 19,100 | 9,600 | 14,900 | 11,200 | 11,900 | 8,900 | 9,500 | 9,500 | 7,600 | 9,500 | 6,000 | 7,500 | 4,800 | 7,200 | 3,800 | 6,700 | |

| Vc = 1500m/min, fz = 0.25 mm/t | ||||||||||||||||||||||

| 100 | DS2015, TH10 | AM | 200 – 2000 | 0.1 – 0.25 | 12,700 | 5,100 | 9,900 | 5,900 | 8,000 | 4,800 | 6,400 | 5,100 | 5,100 | 5,100 | 4,000 | 4,000 | 3,200 | 3,800 | 2,500 | 3,500 | ||

| Vc = 1000m/min, fz = 0.2 mm/t | ||||||||||||||||||||||

| Cast aluminium alloy (Si ≦ 13%) |

75 | DS2015, TH10 | AM | 200 – 2000 | 0.15 – 0.3 | 12,700 | 5,100 | 9,900 | 5,900 | 8,000 | 4,800 | 6,400 | 5,100 | 5,100 | 5,100 | 4,000 | 4,000 | 3,200 | 3,800 | 2,500 | 3,500 | |

| Vc = 1000m/min, fz = 0.2 mm/t | ||||||||||||||||||||||

| 90 | DS2015, TH10 | AM | 200 – 1500 | 0.1 – 0.25 | 10,200 | 3,100 | 8,000 | 3,600 | 6,400 | 2,900 | 5,100 | 3,100 | 4,000 | 3,000 | 3,200 | 2,400 | 2,500 | 2,300 | 2,000 | 2,100 | ||

| Vc = 800m/min, fz = 0.15 mm/t | ||||||||||||||||||||||

| Cast aluminium alloy (Si > 13%) |

130 | DS2015, TH10 | AM | 200 – 1000 | 0.07 – 0.15 | 7,600 | 1,500 | 6,000 | 1,800 | 4,800 | 1,400 | 3,800 | 1,500 | 3,000 | 1,500 | 2,400 | 1,200 | 1,900 | 1,100 | 1,500 | 1,100 | |

| Vc = 600m/min, fz = 0.1 mm/t | ||||||||||||||||||||||

| Copper alloys (Pb > 1%) |

110 | DS2015, TH10 | AM | 200 – 800 | 0.07 – 0.15 | 6,400 | 1,300 | 5,000 | 1,500 | 4,000 | 1,200 | 3,200 | 1,300 | 2,500 | 1,300 | 2,000 | 1,000 | 1,600 | 1,000 | 1,300 | 900 | |

| Vc = 500m/min, fz = 0.1 mm/t | ||||||||||||||||||||||

| Copper alloys | 90 | DS2015, TH10 | AM | 300 – 1000 | 0.1 – 0.15 | 7,600 | 1,800 | 6,000 | 2,200 | 4,800 | 1,700 | 3,800 | 1,800 | 3,000 | 1,800 | 2,400 | 1,400 | 1,900 | 1,400 | 1,500 | 1,300 | |

| Vc = 600m/min, fz = 0.12 mm/t | ||||||||||||||||||||||

| 100 | DS2015, TH10 | AM | 300 – 800 | 0.1 – 0.15 | 6,400 | 1,500 | 5,000 | 1,800 | 4,000 | 1,400 | 3,200 | 1,500 | 2,500 | 1,500 | 2,000 | 1,200 | 1,600 | 1,200 | 1,300 | 1,100 | ||

| Vc = 500m/min, fz = 0.12 mm/t | ||||||||||||||||||||||

| Duroplastics, fiber plastics | – | DS2015, TH10 | AM | 100 – 500 | 0.1 – 0.15 | 3,800 | 900 | 3,000 | 1,100 | 2,400 | 900 | 1,900 | 900 | 1,500 | 900 | 1,200 | 700 | 1,000 | 700 | 800 | 700 | |

| Vc = 300m/min, fz = 0.12 mm/t | ||||||||||||||||||||||

| Hard rubber | – | DS2015, TH10 | AM | 100 – 300 | 0.1 – 0.15 | 2,500 | 600 | 2,000 | 700 | 1,600 | 600 | 1,300 | 600 | 1,000 | 600 | 800 | 500 | 600 | 400 | 500 | 400 | |

| Vc = 200m/min, fz = 0.12 mm/t | ||||||||||||||||||||||

For more information about this product, visit our online e-catalog or download the product report: