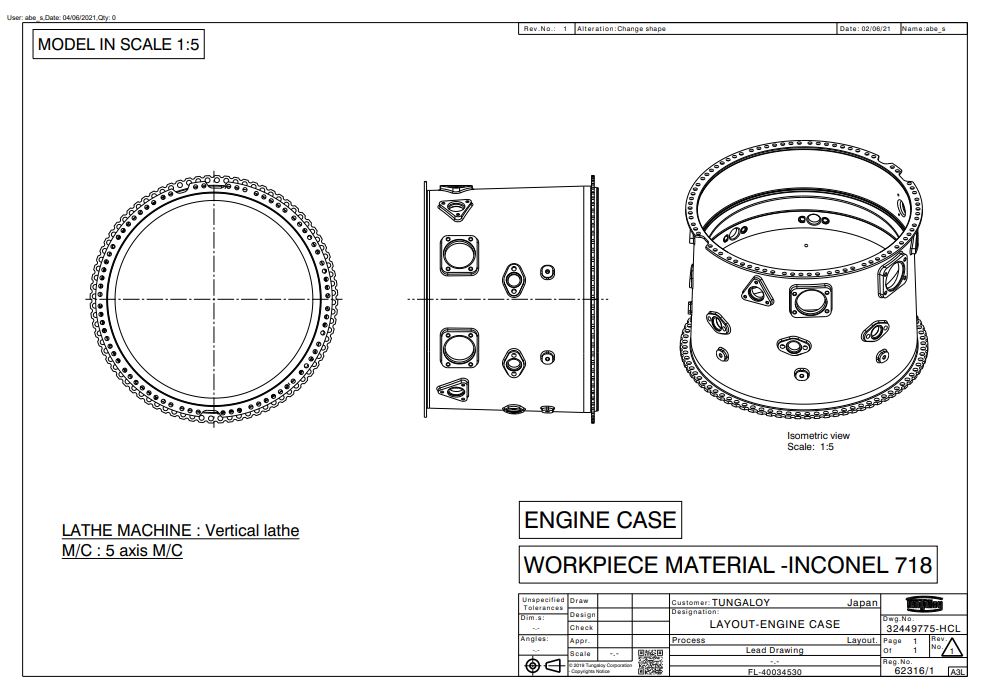

Aerospace – Engine Case

An aircraft engine is a device that sprays fuel into air compressed by turbines to facilitate continuous combustion and generate high-temperature gases. In manufacturing critical components like combustion cases, choosing the right tools tailored to the machining process is essential. The ability to accurately and efficiently machine complex shapes is crucial for achieving high functionality and cost reduction. Tungaloy’s proprietary technology provides effective solutions, including optimal cutting tool shapes and accumulated expertise, even for machining complex-shaped parts made from materials that are difficult to cut and cause rapid tool wear.

Tooling concepts

- Improves productivity and prevents chattering on thin wall parts

- Application of low cutting force tools to achieve high speed and high D.O.C

- In order to maximize the performance of the 5-axis machine, apply multi-functional tools and machining methods such as ramping and contouring

Featured process

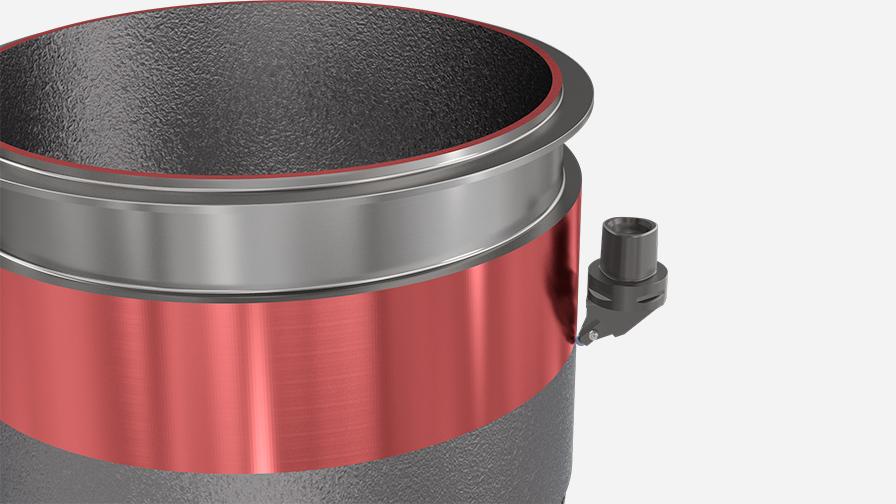

Process 1: OD Rough turning

Benefits

- The TS300 grade is a ceramic grade known for its high toughness and can be applied at a higher D.O.C. even within the ceramic grade category

- By reducing the number of machining paths, the effects of work hardening of materials are reduced and the tool life is extended

- TungCap tooling significantly reduces machine downtime

- TungCap, with two face contacts ensures high tool rigidity and contributes to improving the efficiency of rough machining

![]()

- Sialon ceramic with excellent wear resistance and fracture resistance

- The solution for high-speed and high-efficiency machining of heat-resistant alloys

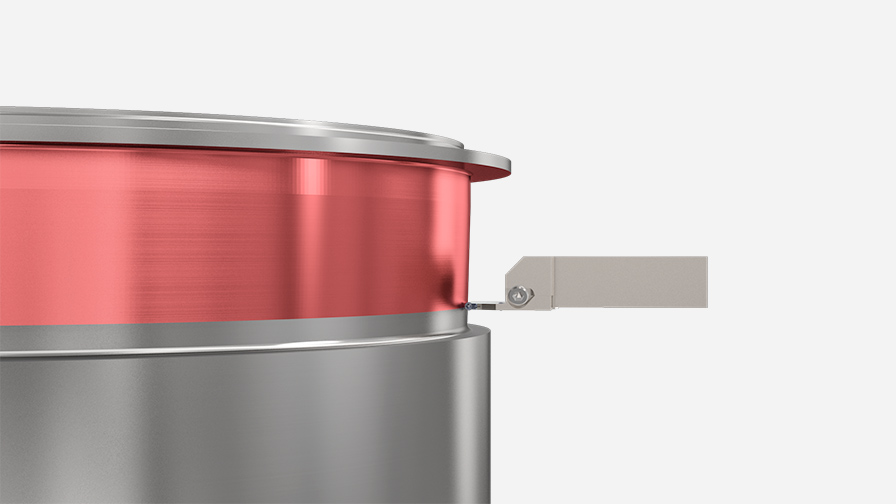

Process 2: OD Finish turning

Benefits

- Applying grooving tools to profiling turning operations allows for machining with a single tool, achieving tool consolidation and reducing machining time.

- External turning with grooving tools induces a pseudo-small approach angle caused by holder flexure, resembling a high-feed cutting edge. This high-feed cutting edge proves effective in prolonging tool life during difficult-to-cut materials machining.

- Multi-functional system for diverse grooving needs

- High rake angle reduces cutting force

- Low cutting force and high rigid insert clamping helps to achieve stable milling processes

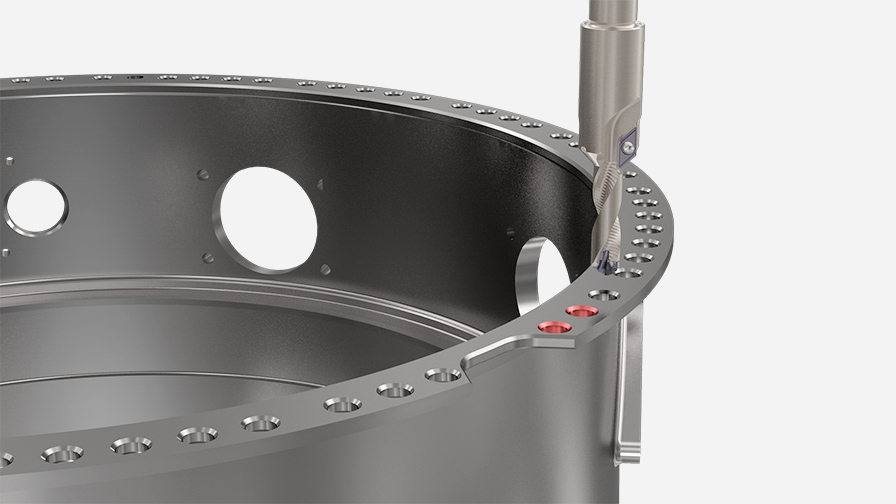

![]()

MTECZ-UN

- Ideal for threading process with a coating film that maintains a sharp cutting edge.

- Maintains a sharp cutting edge and ensures stable screw accuracy.

DMP Drill Head

- Smooth radius edge honing provides low cutting force

- Latest AH9130 grade ensures long tool life