Superior surface quality and process security in small part machining

Cutting edge sharpness is maintained over a long period of time, providing light cutting and excellent surface finish

Applications & Features

Applications

Features

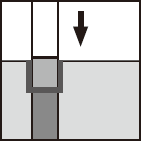

1. For high surface quality

Built-up edge resistant TiCN coating improves surface fi nish quality.

2. Extremely long tool life

Wear-resistant columnar-structured TiCN coating ensures long tool life.

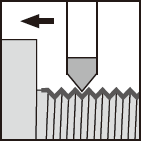

3. Superior process security

Chipping-resistant multi-layered TiAlN coating provides process security.

Grades

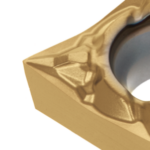

SH7025

![]()

![]()

- P20 – P30 / M20 – M30

- The latest grade with sharp cutting edge designed for small part machining.

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

Practical examples

Example #1

| Workpiece type: | Guide for linear motion bearing |

| Workpiece material: | SUS316 |

| Insert: | DCGT11T302FN-JP |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 150 (m/min) f = 0.03 (mm/rev) ap = 0.1 (mm) Machining: External and face turning Coolant: Wet |

Example #2

| Workpiece type: | Spool pin |

| Workpiece material: | SCM415 |

| Insert: | DCGT11T302FN-JP |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 150 (m/min) f = 0.03 (mm/rev) ap = 0.05 (mm) Machining: External and face turning Coolant: Wet |

Example #3

| Workpiece type: | Pin |

| Workpiece material: | SUS410 / X12Cr13 |

| Insert: | DCGT11T301FN-JP |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 90 (m/min) f = 0.05 (mm/rev) ap = 0.5 (mm) Machining: External turning Coolant: Wet |

Example #4

| Workpiece type: | Flange |

| Workpiece material: | SUM23 |

| Insert: | DCGT11T302FN-JS |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 140 (m/min) f = 0.03 – 0.05 (mm/rev) ap = 3 (mm) Machining: External and face turning Coolant: Wet |

Standard cutting conditions

| ISO | Workpiece material | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed: f (mm/rev) | |||

|---|---|---|---|---|---|---|---|---|---|

| RE < 0.03 | RE < 0.1 | RE < 0.2 | RE < 0.4 | ||||||

|

Carbon steel Alloy steel |

JP | SH7025 | 10 – 200 | 0.05 – 2.5 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | – |

| JS | SH7025 | 10 – 200 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 | ||

|

Stainless steel | JP | SH7025 | 10 – 200 | 0.05 – 2.5 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | – |

| JS | SH7025 | 10 – 200 | 0.5 – 3 | 0.02 – 0.03 | 0.02 – 0.05 | 0.02 – 0.1 | 0.05 – 0.2 | ||

For more information about this product, visit our online e-catalog or download the product report: