Economical double-sided positive insert

Innovative geometry and seat interface ensures stability and high performance

Applications & Features

Applications

Features

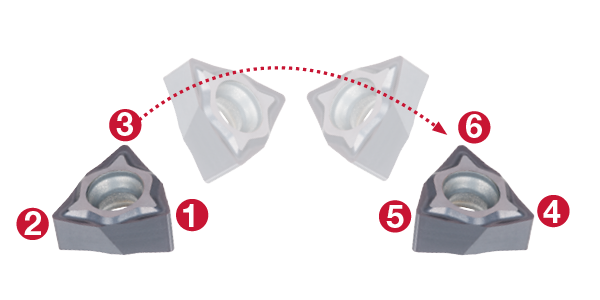

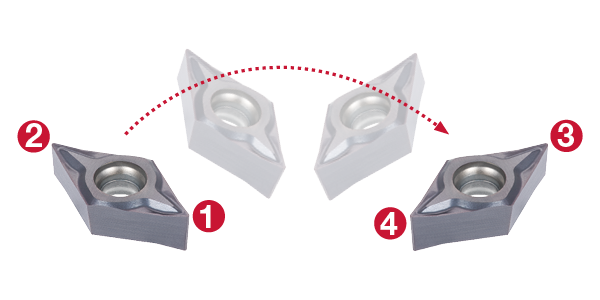

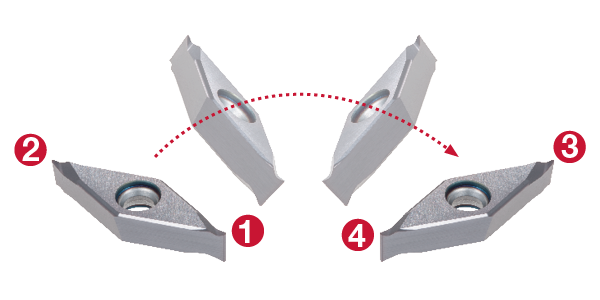

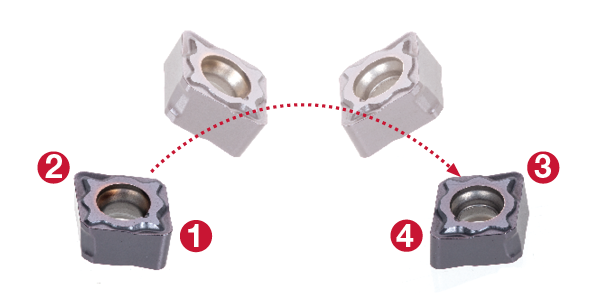

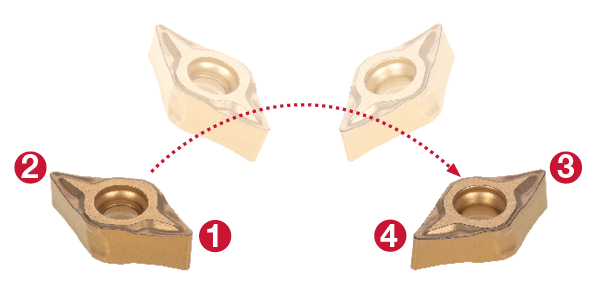

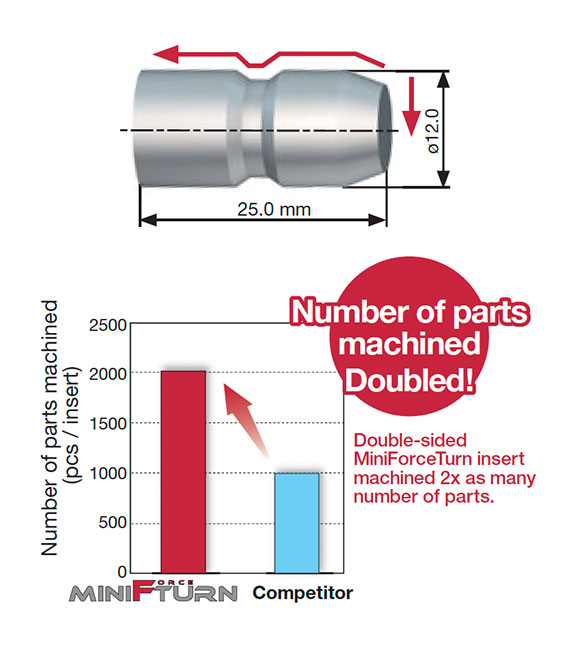

1. Economical double-sided positive insert

WXGU

DXGU

VXGU

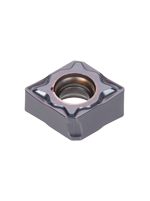

CXMU

DXMU

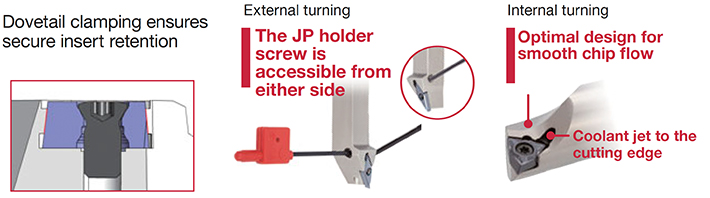

2. Toolholders

3. Light cutting chipbreaker

- JS chipbreaker – features and benefits

- Provides excellent chip control in a wide range of applications.

- A large inclination angle on the cutting edge ensures free cutting.

- Excellent cutting edge integrity for smooth surface finishing.

- Note: Due to chipbreaker profile, max ap for face or ID turning is 1 mm.

Inserts & Grades

Inserts

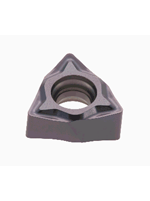

WX-U inserts

- 6 positive cutting edges

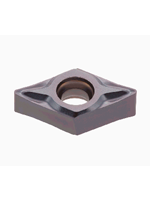

DX-U Inserts

- 4 positive cutting edges

VX-U Inserts

- 4 positive cutting edges

Main Grades

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- High wear resistance

- Designed for machining steel and stainless steel

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

GT9530

![]()

![]()

- High wear resistance

- Excellent surface quality in finishing

Toolholders

Practical examples

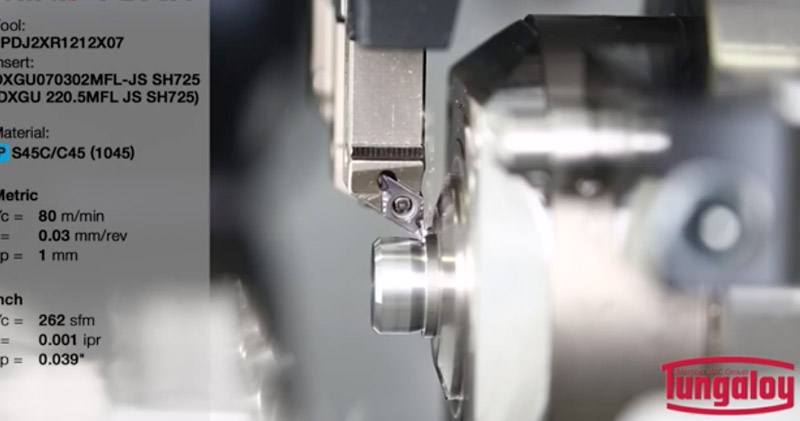

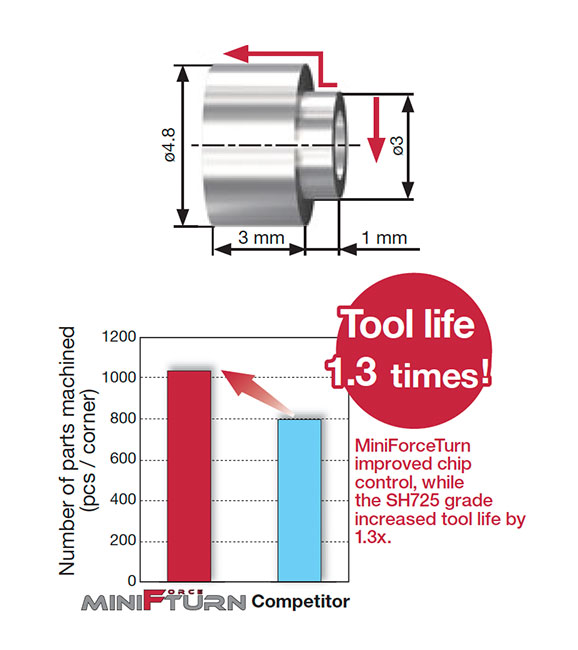

Example #1

Miniature / Electronic Industry

| Part: | Shaft |

| Material: | SUS316 / X5CrNiMo17-12-3 |

| Toolholder: | JSDJ2XR1212X07 |

| Insert: | DXGU070301MFL-JS |

| Grade: | SH725 |

| Cutting conditions: | Vc = 61 (m/min) f = 0.02 (mm/rev) ap = 0.12 (mm) Application: External turning Coolant: Wet |

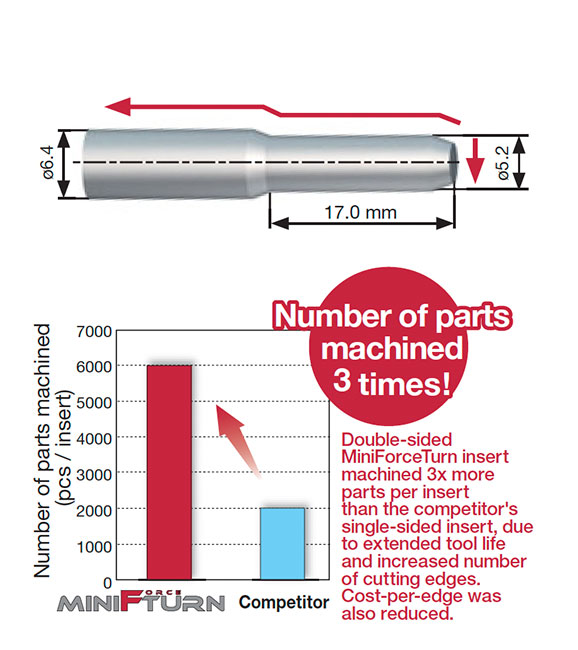

Example #2

Miniature / Electronic Industry

| Part: | Shaft |

| Material: | S45C /C45 |

| Toolholder: | JSWL2XR1212X04 |

| Insert: | WXGU040302L-TS |

| Grade: | AH725 |

| Cutting conditions: | Vc = 66 – 80 (m/min) f = 0.15 (mm/rev) ap = 0.6 (mm) Application: External turning Coolant: Wet |

Example #3

General Engineering

| Part: | Shaft |

| Material: | Alloy steels |

| Toolholder: | JSDJ2XR1212X07 |

| Insert: | DXGU070301ML-JSS |

| Grade: | AH725 |

| Cutting conditions: | Vc = 66 – 80 (m/min) f = 0.15 (mm/rev) ap = 0.6 (mm) Application: External turning Coolant: Wet |

Standard cutting conditions

For external turning

| Applications | ISO | Workpiece material | Priority | Chip- breaker |

Grade | Cutting speedspeed Vc (m/min) |

Depth of cut ap (mm) |

FeedFeed f (mm/rev) |

|---|---|---|---|---|---|---|---|---|

| For swiss type automatic lathes | Low carbon steel SS400, etc. E275A, etc.SS400, etc. E275A, etc. Carbon steel S45C, etc. C45, etc.Carbon steel S45C, etc. C45, etc. Low alloy steel SCM415, etc. 18CrMo4, etc.Low alloy steel SCM415, etc. 18CrMo4, etc. Alloy steel SCM440, etc. 42CrMo4, etc. |

First choice | JS | SH725 | 50 – 180 | 0.1 – 3 | 0.03 – 0.1 | |

| With high sharpness | JSS | SH725 | 50 – 180 | 0.1 – 1.5 | 0.03 – 0.1 | |||

| Stainless steel (Austenitic) SUS304, etc. X5CrNi18-9, etc.SUS304, etc. X5CrNi18-9, etc. Stainless steel (Martensitic and ferritic) SUS430, etc. X6Cr17, etc.Stainless steel (Martensitic and ferritic) SUS430, etc. X6Cr17, etc. Stainless steel (Precipitation hardened)SUS630, etc. X5CrNiCuNb16-4, etc. |

First choice | JS | SH725 | 50 – 180 | 0.1 – 1.25 | 0.03 – 0.1 | ||

| With high sharpness | JSS | SH725 | 50 – 180 | 0.1 – 1.5 | 0.03 – 0.1 | |||

| For small size CNC lathes | Low carbon steel SS400, etc. E275A, etc.SS400, etc. E275A, etc. Carbon steel S45C, etc. C45, etc.Carbon steel S45C, etc. C45, etc. Low alloy steel SCM415, etc. 18CrMo4, etc.Low alloy steel SCM415, etc. 18CrMo4, etc. Alloy steel SCM440, etc. 42CrMo4, etc. |

First choice | SS | AH725 | 50 – 180 | 0.15 – 1.5 | 0.05 – 0.2 | |

| TS | AH725 | 50 – 180 | 0.3 – 2 | 0.08 – 0.3 | ||||

| For improved surface finish | SS | NS9530 | 50 – 200 | 0.15 – 1.5 | 0.05 – 0.2 | |||

| TS | NS9530 | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||||

| For wear resistance | SS | GT9530 | 50 – 250 | 0.15 – 1.5 | 0.05 – 0.2 | |||

| TS | GT9530 | 50 – 250 | 0.3 – 2 | 0.08 – 0.3 | ||||

| Stainless steel (Austenitic) SUS304, etc. X5CrNi18-9, etc.SUS304, etc. X5CrNi18-9, etc. Stainless steel (Martensitic and ferritic)SUS430, etc. X6Cr17, etc.Stainless steel (Martensitic and ferritic)SUS430, etc. X6Cr17, etc. Stainless steel (Precipitation hardened)SUS630, etc. X5CrNiCuNb16-4, etc. |

First choice | SS | AH725 | 50 – 150 | 0.15 – 1.5 | 0.05 – 0.2 | ||

| For impact resistance | TS | AH725 | 50 – 150 | 0.3 – 2 | 0.08 – 0.3 |

For internal turning

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|

|---|---|---|---|---|---|---|

| First choice | Second choice | |||||

| Low carbon steel / Low alloy steel | T9215 | – | 120 – 350 | 0.3 – 2 | 0.08 – 0.3 | |

| T9225 | – | 100 – 300 | 0.3 – 2 | 0.08 – 0.3 | ||

| AH8015 | – | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | AH725 | 50 – 180 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | NS9530 | 80 – 250 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | GT9530 | 80 – 300 | 0.3 – 2 | 0.08 – 0.3 | ||

| Carbon steel / Alloy steel | T9215 | – | 80 – 350 | 0.3 – 2 | 0.08 – 0.3 | |

| T9225 | – | 80 – 300 | 0.3 – 2 | 0.08 – 0.3 | ||

| AH8015 | – | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | AH725 | 50 – 180 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | NS9530 | 80 – 250 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | GT9530 | 80 – 300 | 0.3 – 2 | 0.08 – 0.3 | ||

| Stainless steel (Austenitic) | AH8015 | – | 50 – 150 | 0.3 – 2 | 0.08 – 0.3 | |

| – | AH725 | 50 – 150 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | T9215 | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||

| Stainless steel (Martensitic and ferritic) | AH8015 | – | 50 – 150 | 0.3 – 2 | 0.08 – 0.3 | |

| – | AH725 | 50 – 150 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | T9215 | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||

| Stainless steel (Precipitation hardening) | AH8015 | – | 50 – 150 | 0.3 – 2 | 0.08 – 0.3 | |

| – | AH725 | 50 – 150 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | T9215 | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||

| Grey cast iron | T9215 | – | 100 – 350 | 0.3 – 2 | 0.08 – 0.3 | |

| T9225 | – | 100 – 350 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | AH8015 | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | AH725 | 50 – 180 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | NS9530 | 80 – 250 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | GT9530 | 80 – 300 | 0.3 – 2 | 0.08 – 0.3 | ||

| Ductile cast iron | T9215 | – | 100 – 350 | 0.3 – 2 | 0.08 – 0.3 | |

| T9225 | – | 100 – 350 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | AH8015 | 50 – 200 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | AH725 | 50 – 180 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | NS9530 | 80 – 250 | 0.3 – 2 | 0.08 – 0.3 | ||

| – | GT9530 | 80 – 300 | 0.3 – 2 | 0.08 – 0.3 | ||

| Aluminum alloys | KS05F | – | 100 – 300 | 0.3 – 2 | 0.08 – 0.3 | |

| Copper alloys | KS05F | – | 100 – 300 | 0.3 – 2 | 0.08 – 0.3 | |

| Titanium alloys | AH8015 | – | 20 – 80 | 0.3 – 2 | 0.08 – 0.3 | |

| Nickel-based alloys | AH8015 | – | 20 – 80 | 0.3 – 2 | 0.08 – 0.3 | |

| Hardened steel | BXA20 | – | 50 – 220 | 0.12 – 0.8 | 0.1 – 0.3 | |

| – | BXA10 | 50 – 220 | 0.12 – 0.8 | 0.1 – 0.3 | ||

CBN-tipped DXGQ/U inserts

| ISO | Grade | Workpiece condition | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|---|---|---|---|---|---|

| BXA10 | Continuous | 100 – 230 | 0.05 – 0.5 | 0.05 – 0.3 | |

| Light interrupted | 100 – 230 | 0.05 – 0.3 | 0.05 – 0.2 | ||

| BXA20 | Continuous | 60 – 180 | 0.05 – 0.5 | 0.05 – 0.3 | |

| Interrupted | 60 – 180 | 0.05 – 0.3 | 0.05 – 0.2 | ||

| BR35F | Heavy interrupted | 50 – 150 | 0.05 – 0.3 | 0.05 – 0.2 |

For more information about this product, visit our online e-catalog or download the product report: