Automotive – EV Motor case

With the spread of electric vehicles (EV) and hybrid vehicles, the need for traction motors is increasing.

A traction motor is the heart of an automobile that replaces the engine, and efforts are being made to improve its efficiency and reduce its size and weight in order to extend the torque characteristics that determine the dynamic performance of automobiles and the cruising range. In addition, the demand for quality such as quietness and high reliability is rapidly increasing in order to a comfortable car life.

The EV motor case is one of the main parts that make up the traction motor and is becoming thinner and more complicated in shape due to the need to reduce weight. Machining of such thin-walled and complicated-shaped workpieces tends to be difficult due to the reduction in rigidity of the workpieces and fixtures. Tungaloy proposes an optimal tool lineup and processing methods for motor case machining, and contributes to the problem solving and the productivity improvement.

Tooling concepts

- Improved productivity by applying a high-density cutter

- A cutter incorporating deburring inserts that prevents the generation of burrs in finish face milling is applied. Contributes to reduction of load in deburring process and improvement of product quality

- Applying a PCD insert with a 3D breaker eliminates chip issues in aluminum turning

- Use of head changeable tools to reduce machine down time and effort of tool replacement and management

Featured process

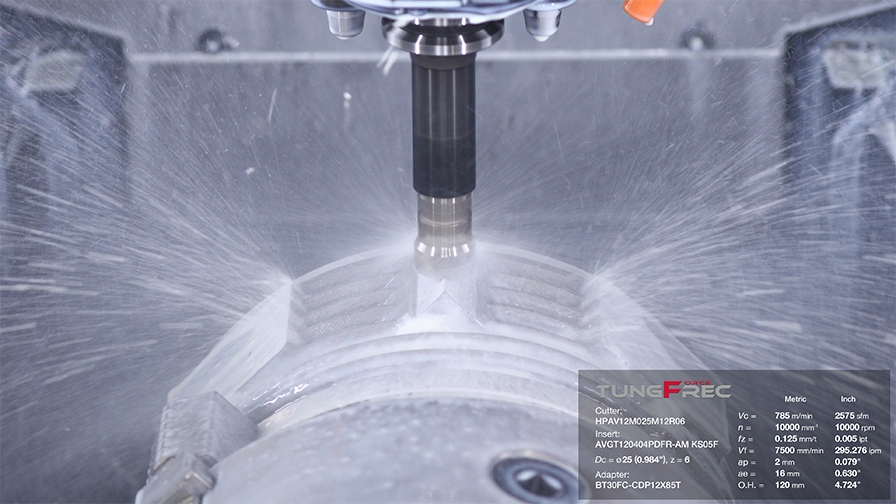

AM insert (For non-ferrous metal)

- Shoulder cutter with unique V-bottom insert for maximum efficiency

- Contributes to improved machining efficiency with high-density specifications

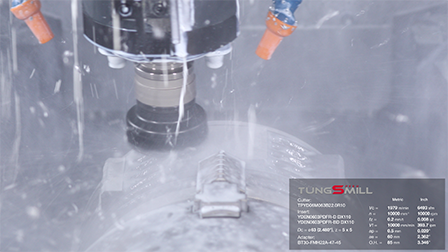

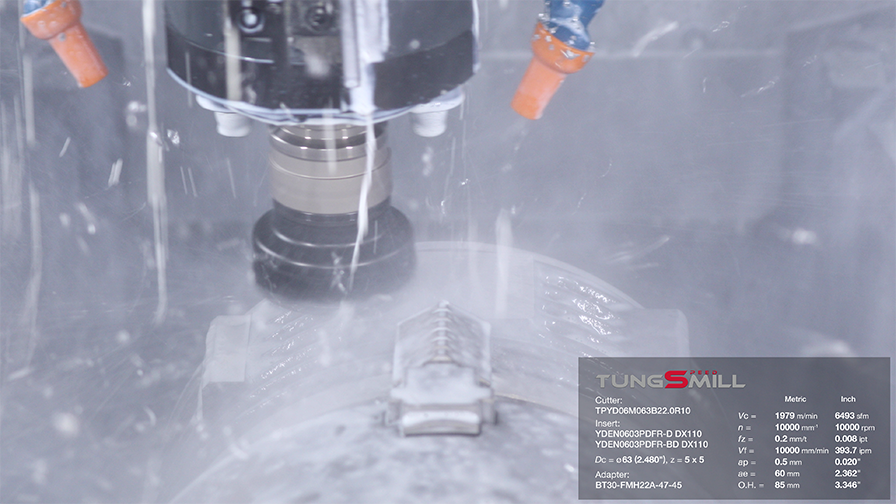

Process 2: Finnish face milling

Benefits

- The high-density cutter improves the machining efficiency of finish face milling, Especially suitable for casing components

- Easy to adjust the cutting edge height by using the unique height adjustment mechanism.Significantly reduces the time required for insert height adjustments which is difficult with high-density cutters

- A deburring wiper insert is available. Prevents the generating of burrs and improves the machined surface quality, which is important in finish face milling operations

D insert (Standard insert)

BD insert (Deburring insert)

- Achieves high-efficiency machining by increasing the number of teeth

- Uses a unique clamping mechanism to prevent insert scattering. Supports high-speed rotation

- New cutting edge adjustment mechanism “Cam Adjust” greatly reduces cutting edge height adjustment work time

AM insert (For non-ferrous metal)

- Shoulder cutter with unique V-bottom insert for maximum efficiency

- Contributes to improved machining efficiency with high-density specifications

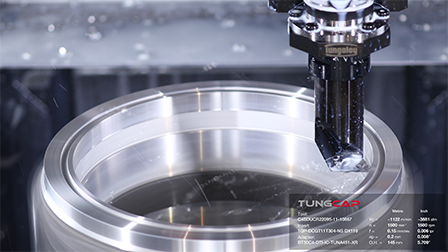

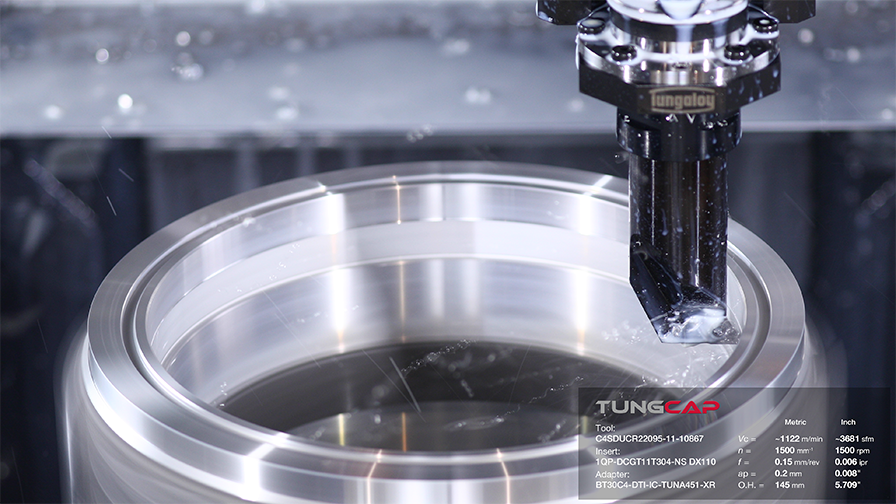

Process 4: OD /ID finish turning

Benefits

- PSC holder is applied to turning tools on multitasking machine. Ensures high tool rigidity even in the turning process for multitasking machines that tend to have long overhang lengths

- Applied PCD insert with new 3D chip breaker. Excellent chip control performance even with PCD inserts by applying a 3D chip breaker design

- Unique 3D chip breaker shape eliminates chip issues in aluminum alloy turning

- Good chip control is possible in a wide cutting area

- Also suitable for turning complicated shaped aluminum components that cause variations in D.O.C.

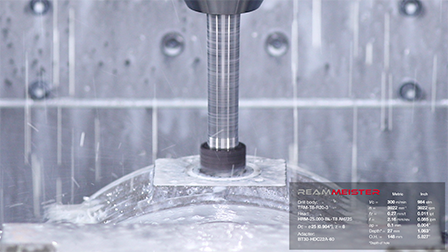

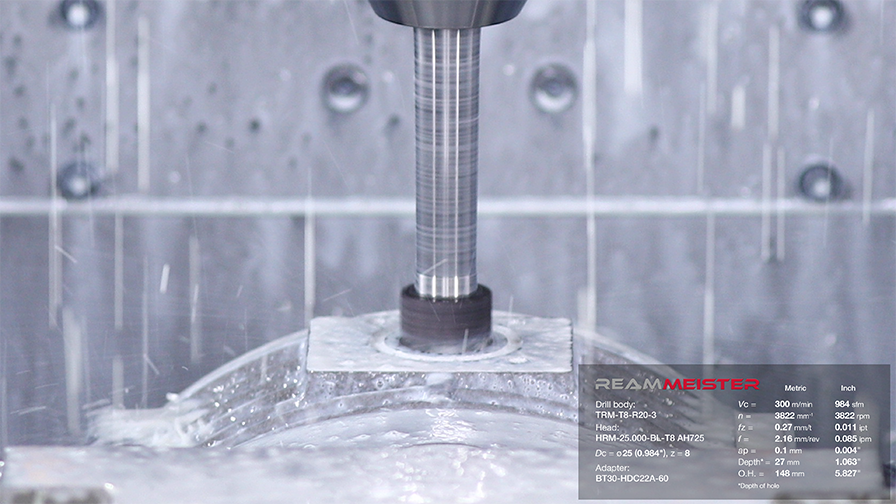

Process 5: Reaming

Benefits

- BL type head for through hole drilling discharges chips forward

- Evacuating chips forward prevents deterioration of hole surface quality caused by chips damaging the machined surface during chip evacuation

- Evacuating chips forward prevents chip disposal problems such as chips getting entangled in the tool

BL head (For through holes)

- Head changeable reamer compatible with H7 hole accuracy

- Lineup of 2 types of heads: AS type for blind holes and BL type for through holes

- The BL type head for through hole evacuates chips forward, greatly contributing to the prevention of chip control problems

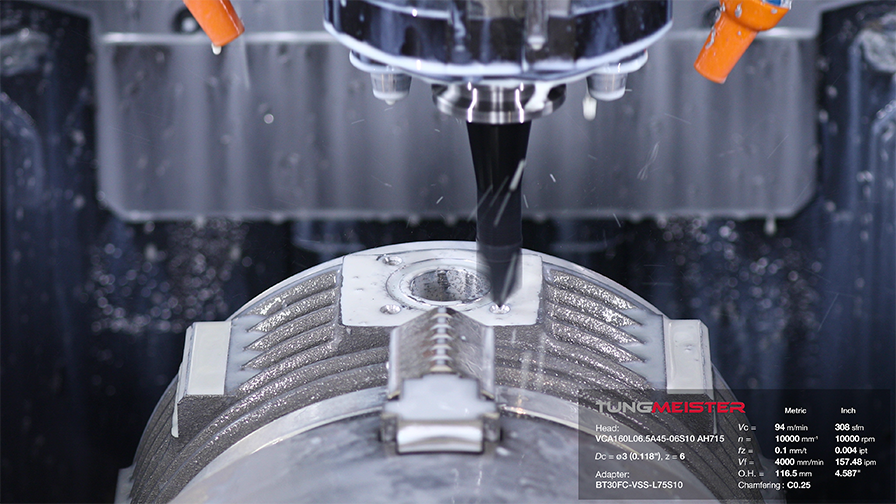

VCA head

- Head changeable end mill with a wide variety of head and shank combinations

- Abundant head lineup including square, high feed, ball, chamfer, drilling and slotting geometries

- The simple and high-precision mounting mechanism dramatically shortens the tool change time