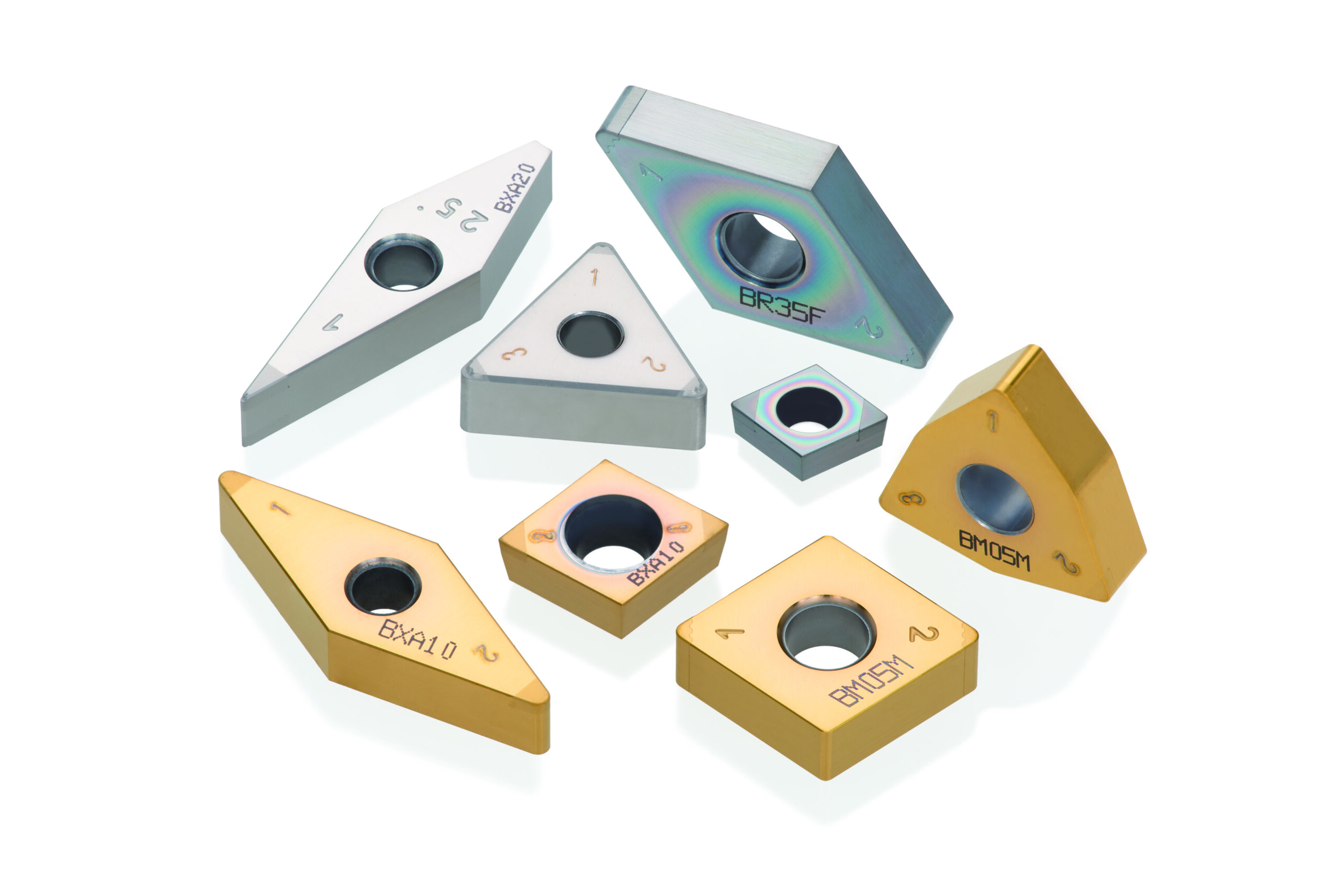

Iwaki, Japan – September, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its Coated CBN Series (BM05M/BXA10/BXA20/BR35F), strengthening its product portfolio with the addition of the new BM05M grade targeted at high-speed machining of hardened steel. The enhanced lineup now comprises four coated CBN grades, offering outstanding wear resistance, extended tool life, and a flexible grade selection system tailored to diverse machining conditions and applications.

Challenges and Trends

In mass production environments, particularly those focused on automotive components, there is a growing demand for higher cutting speeds and improved productivity when machining hardened steel. However, conventional CBN grades have faced significant challenges in this area.

One of the major issues has been the short tool life during high-speed machining, especially due to crater wear, which leads to premature tool failure. As a result, improving cost performance with high-cost CBN inserts has been difficult, making it challenging to balance high-speed machining with long tool life.

These conditions have created a strong need for new solutions that can deliver higher efficiency and stable performance in hardened steel machining.

Product Overview

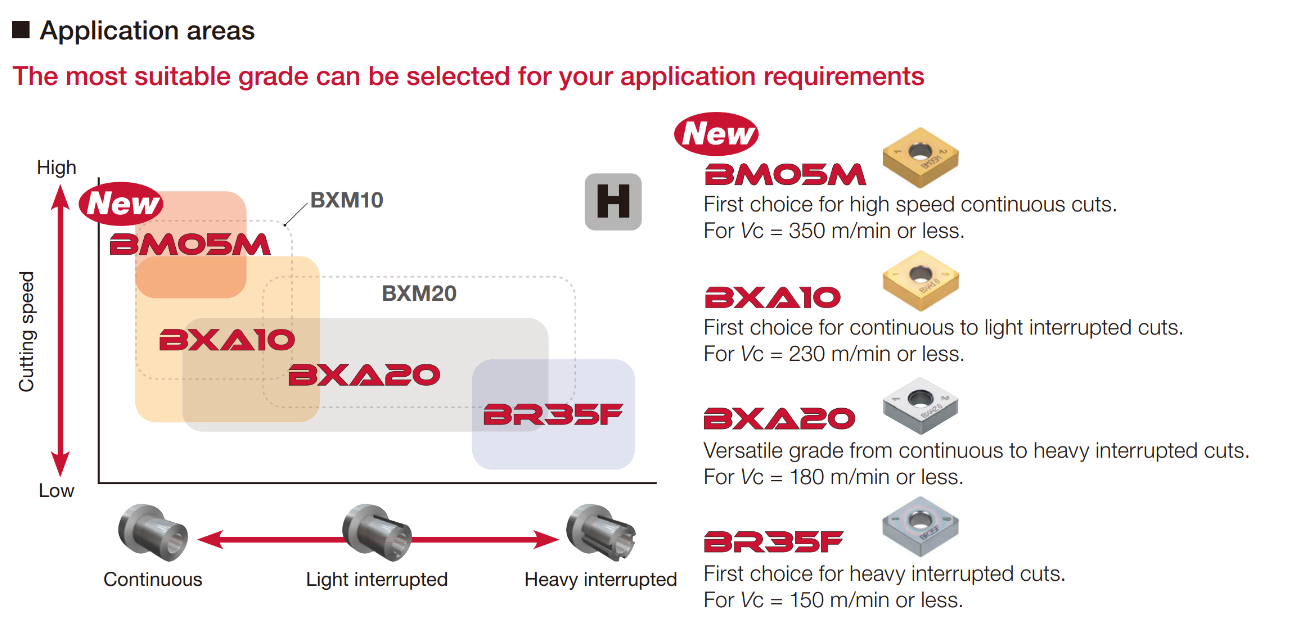

The Coated CBN series BM05M/BXA10/BXA20/BR35F for high-precision machining of hardened steel offers excellent wear resistance and thermal stability, delivering long tool life and consistent performance even in interrupted cutting. A variety of grades are available to suit diverse machining conditions.

Benefits and Features

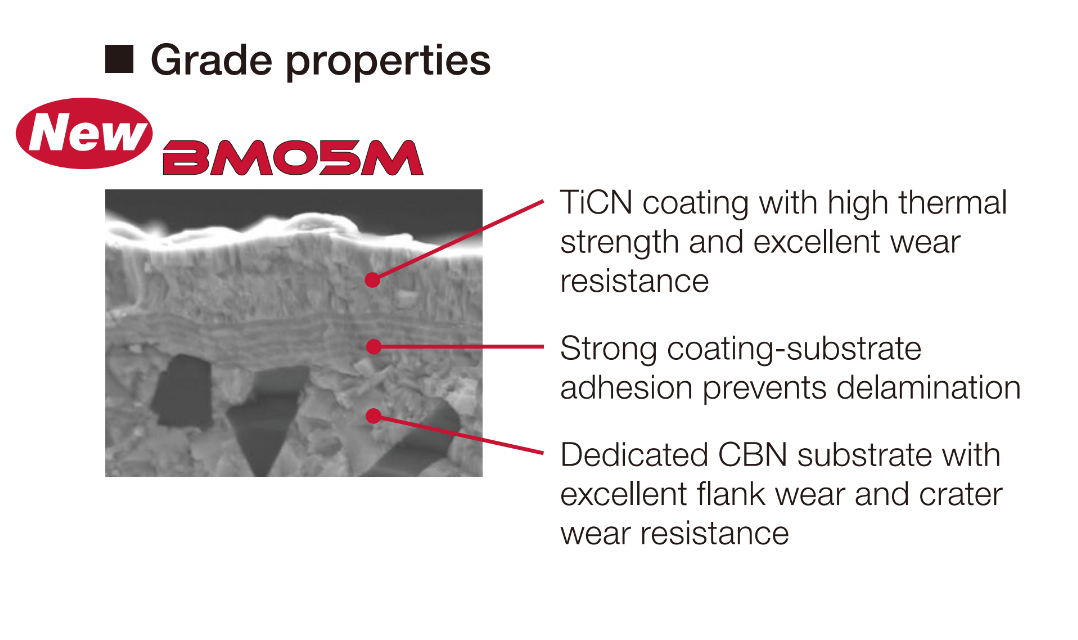

Feature 1: Excellent Wear Resistance in High-Speed Machining

- Utilizes a TiCN-based high-hardness coating that delivers outstanding wear resistance even at elevated temperatures

- Specially engineered CBN substrate suppresses flank wear and crater wear

- Achieves long tool life in continuous high-speed machining of hardened steel at cutting speeds over Vc = 200 m/min

Feature 2: Flexible Grade Selection to Match Machining Conditions

- Addition of BM05M expands the coated CBN lineup to four grades

- Enables optimal grade selection according to machining conditions and workpiece material

- Supports a wide range of needs from high-precision to high-efficiency machining

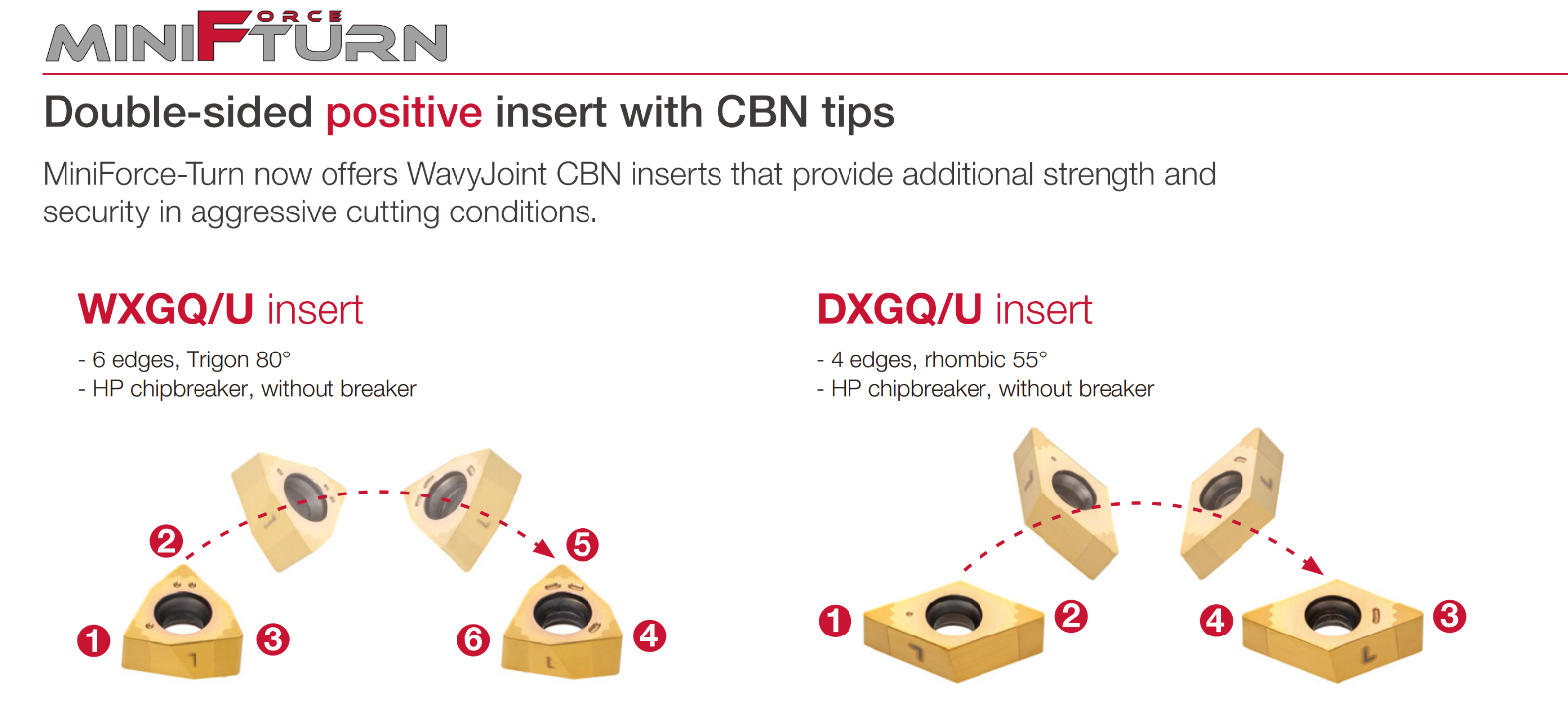

Feature 3: Versatile Insert Shapes for a Wide Range of Applications

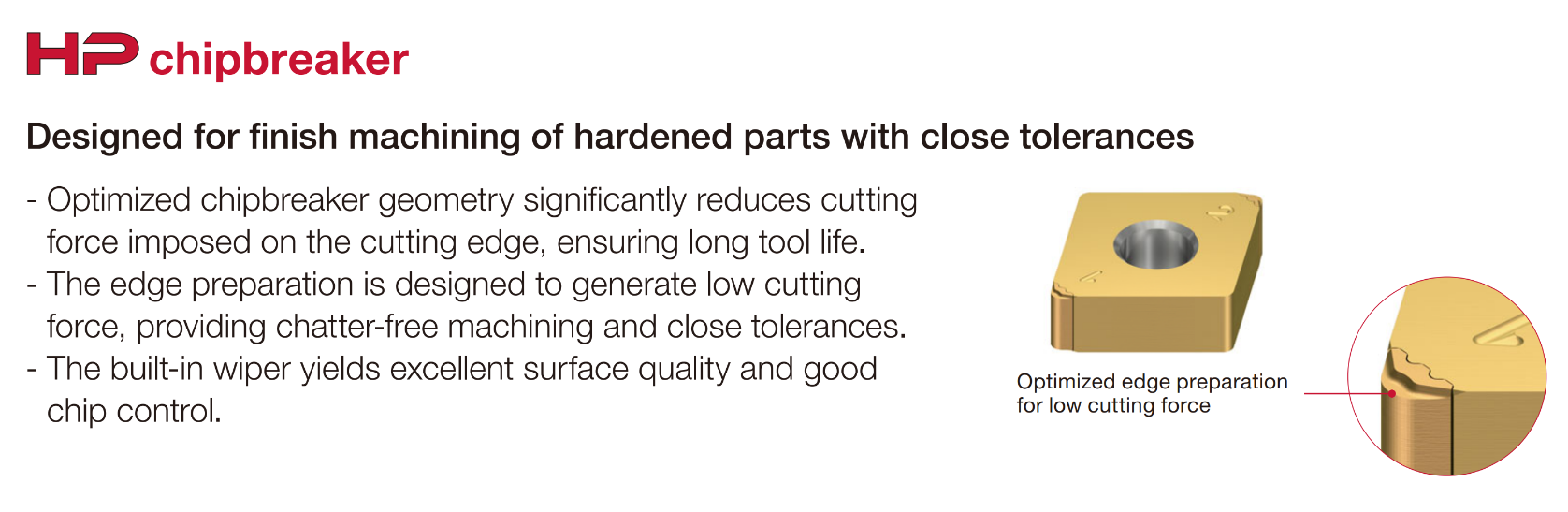

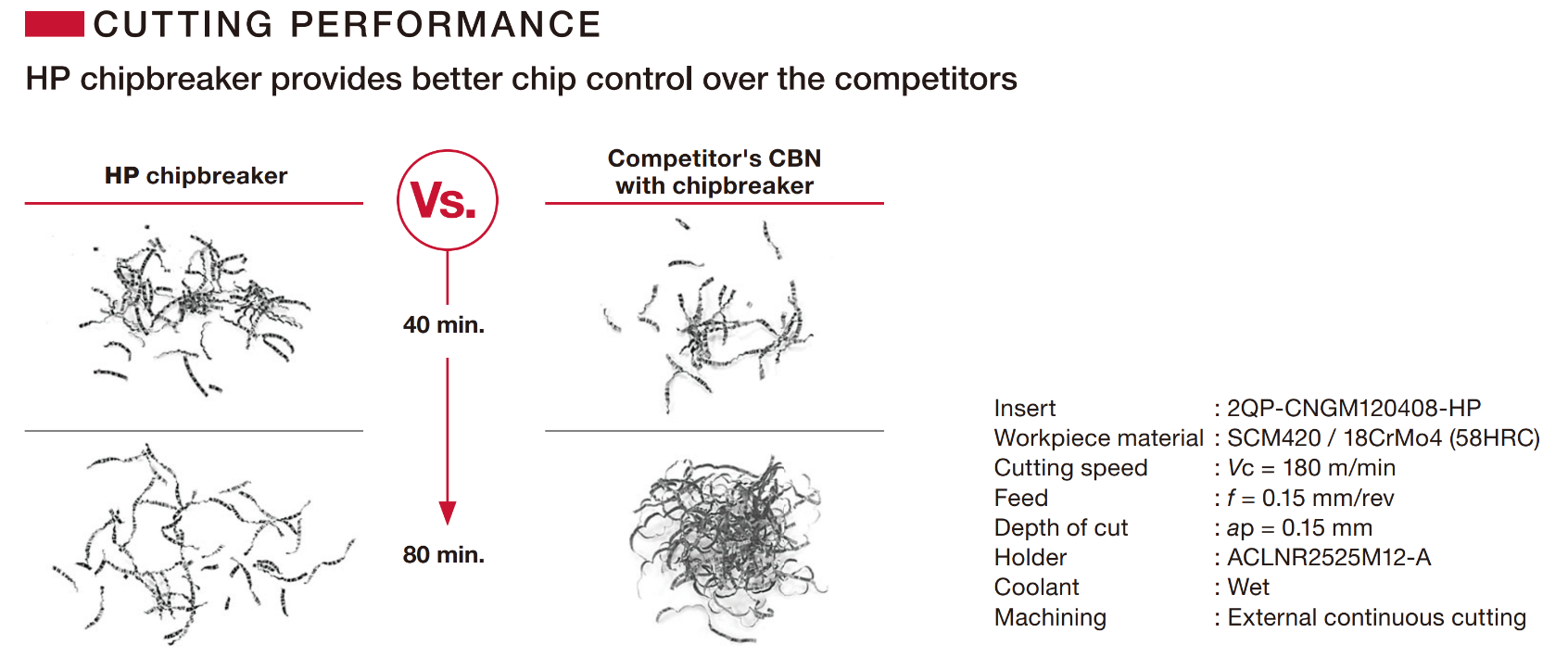

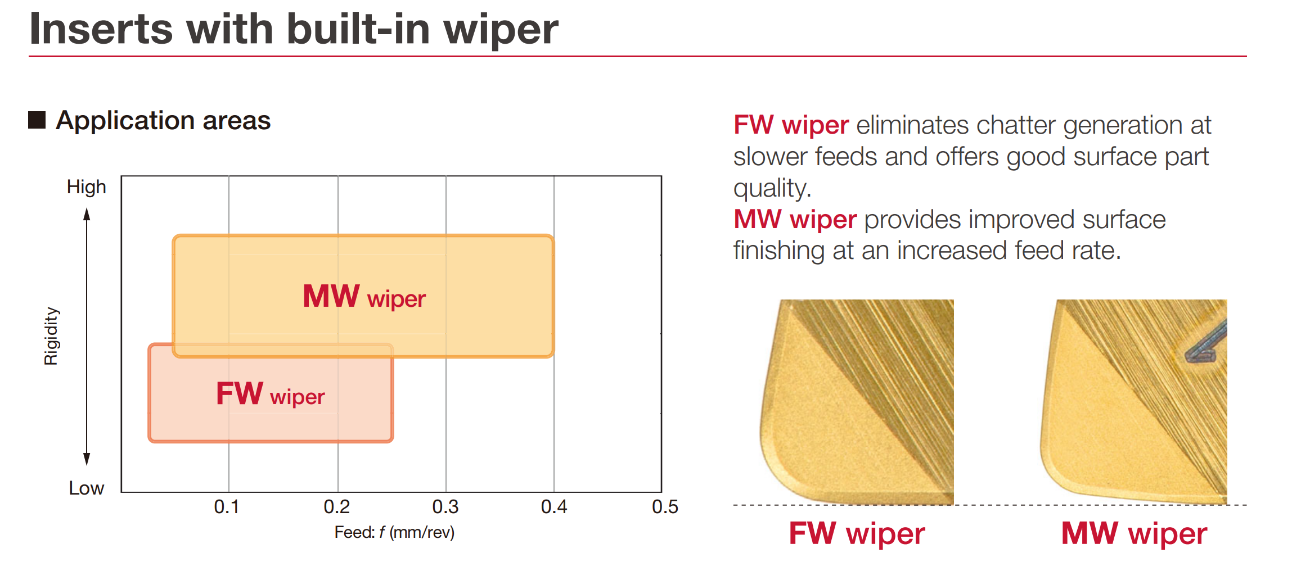

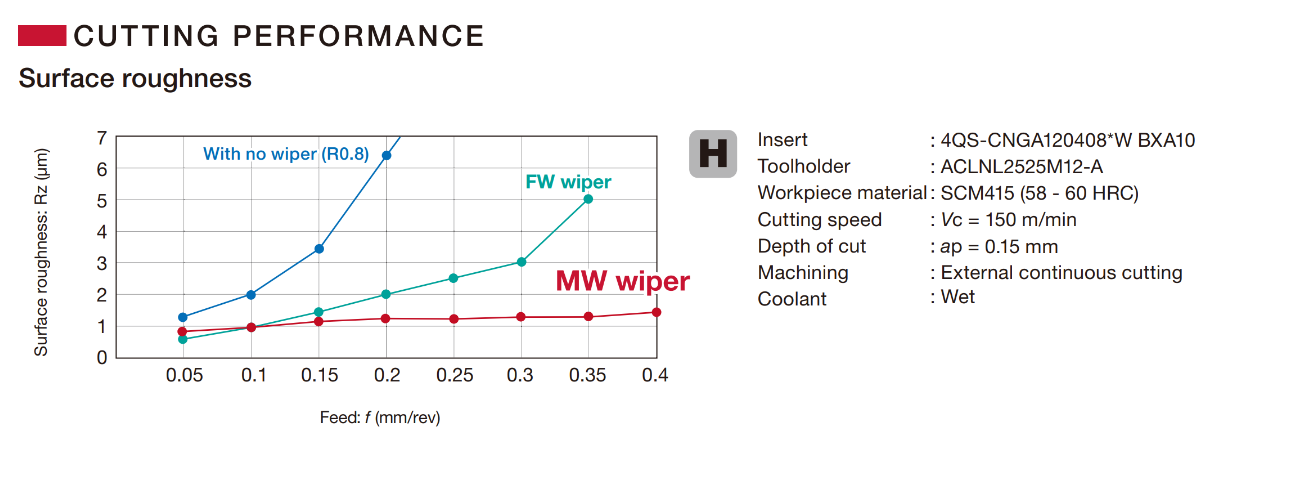

- Offers a variety of insert geometries including chipbreakers, wiper inserts, and MiniForceTurn

- Delivers optimal cutting performance for every finishing

- Contributes to reduced tool change frequency and stabilized machining quality

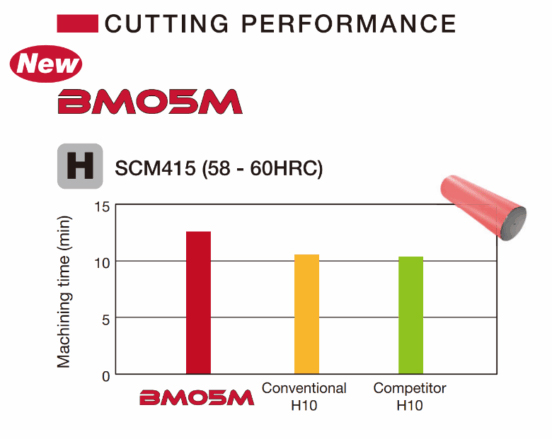

Cutting Performance

Success Stories

IMPROVED TOOL LIFE

BM05M, with excellent crater wear resistance, provided 1.5x tool life increase at a 1.4x cutting speed over the competitor.

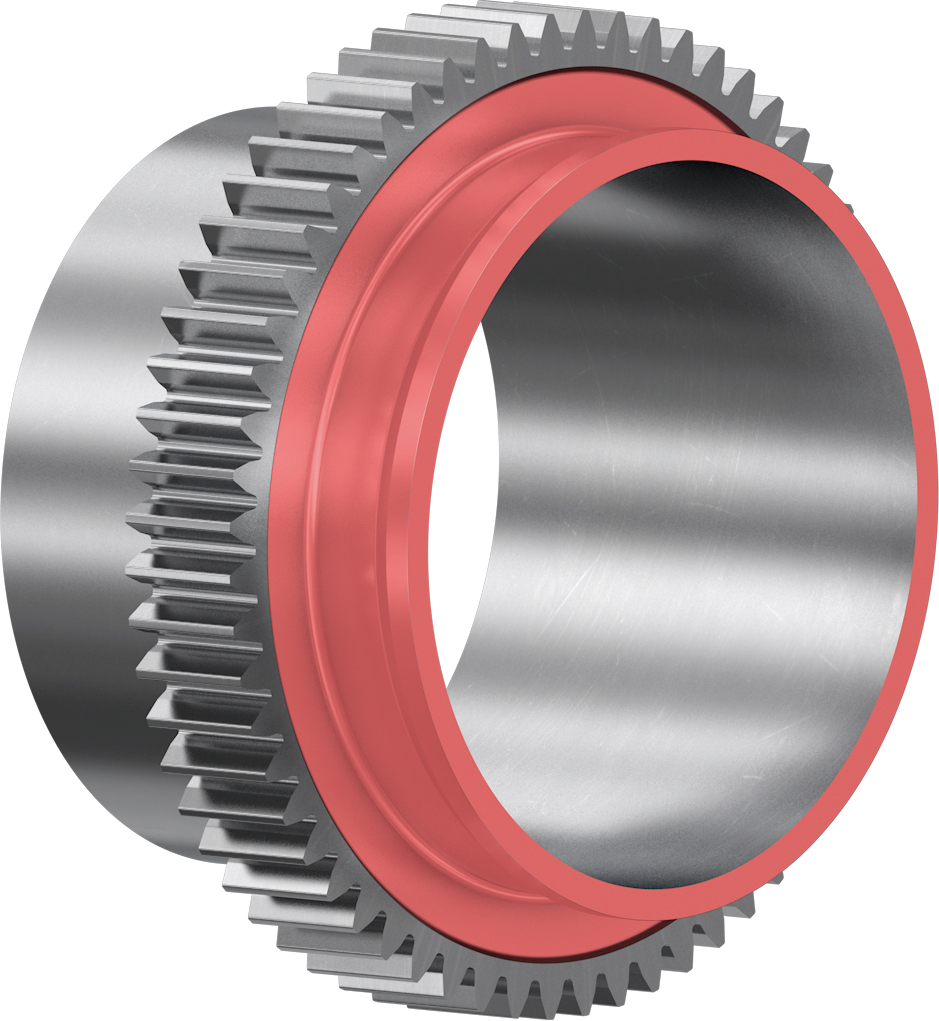

| Industry | Automotive |

| Component | Gear |

| Material ISO code | |

| Work material | SCM420 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External & Face turning |

| Product name | BM05M |

| TSR No. | 5367T |

IMPROVED TOOL LIFE

BM05M, combined with FW wiper, provided double tool life at increased feeds and speeds over the competitor CBN insert with wiper. Part surface quality was also improved.

| Industry | Automotive |

| Component | Gear |

| Material ISO code | |

| Work material | 20MnCrS5 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | Internal turning |

| Product name | BM05M |

| TSR No. | 5368T |