Iwaki, Japan – April, 2024 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungTurnJet series with the introduction of new double clamp-style internal coolant holders for V/YN1604 and TN1604 inserts. Designed with enhanced clamping rigidity and dual-direction coolant supply, the new holders ensure stable cutting performance in difficult-to-machine materials and support both hose and direct coolant connections for greater machine compatibility.

Challenges and Trends

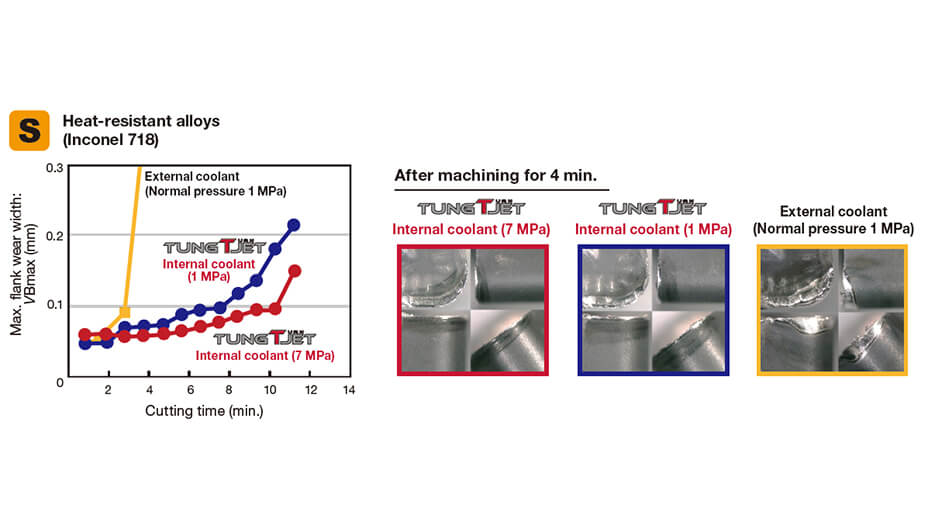

In recent years, the use of heat-resistant alloys has been increasing in industries such as aerospace and medical devices. While these materials offer excellent corrosion resistance and durability, they are also notoriously difficult to machine. In manufacturing environments, challenges such as chip control and inconsistent insert tool life have become increasingly apparent. In particular, external turning operations require stable cutting performance and reliable coolant delivery to ensure proper edge cooling and chip evacuation. As a result, there is a strong demand for solutions that enable efficient machining of these difficult-to-cut materials.

Product Overview

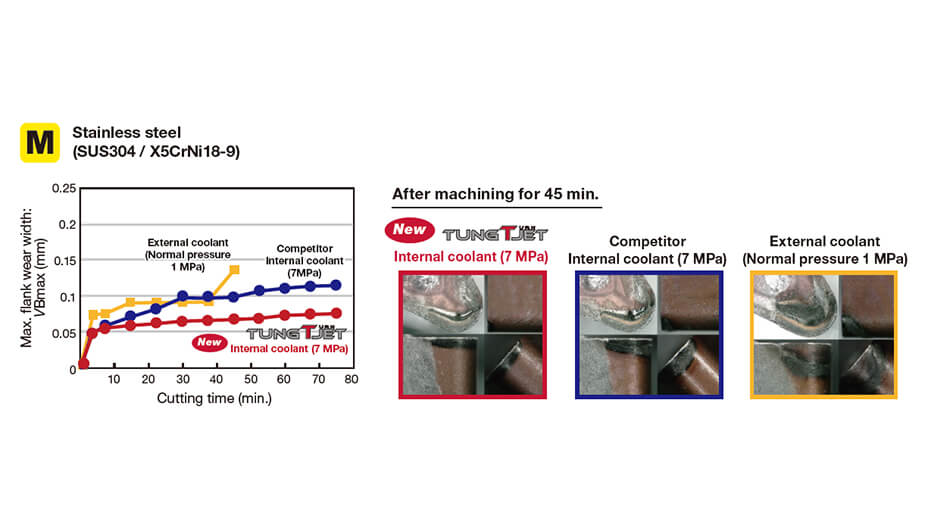

The high-pressure coolant system “TungTurn-Jet” extends tool life and improves machining stability by delivering coolant directly to the cutting edge during operation. It is especially effective in difficult-to-cut materials such as stainless steel.

Benefits and Features

High-Rigidity Double Clamp Structure for Stable Machining and Enhanced Coolant Supply.

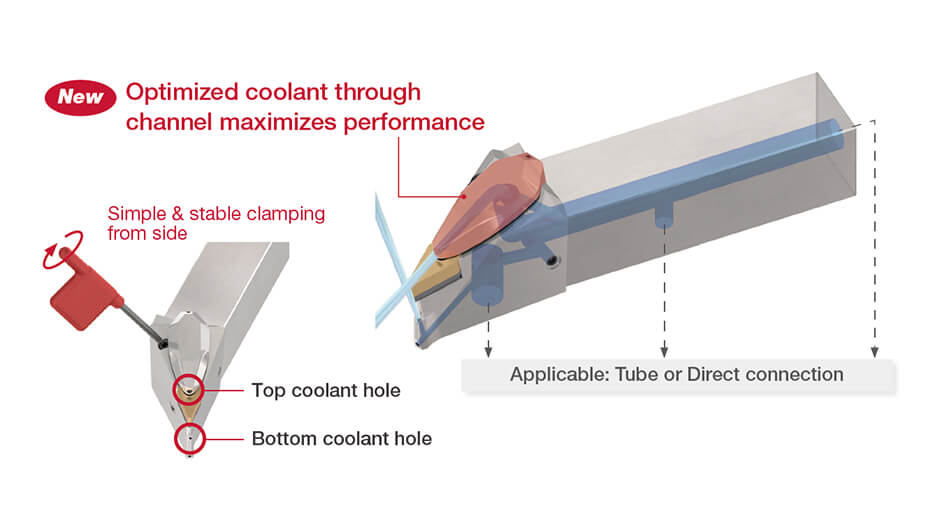

– A newly designed clamp structure improves the overall rigidity of the toolholder.

– Reduces chatter and deflection during cutting to ensure stable machining.

– Optimally positioned coolant channels within the clamp enable reliable coolant delivery directly to the cutting edge.

Improved Chip Evacuation and Tool Life Through Dual-Direction Coolant Supply

– Coolant supplied from the upper clamp efficiently removes chips from the cutting area.

– Coolant from the lower part of the holder directly cools the cutting edge, reducing wear.

– Prevents chip entanglement and recutting, significantly enhancing surface finish and extending tool life.

Flexible Tooling Options Compatible with a Wide Range of Inserts and Holders

– Supports three cutting edge geometries (J, Q, V) for V/YN1604 inserts.

– Compatible with G geometry for TN1604 inserts, with holder options in 20 mm and 25 mm square sizes.

– Available with both hose connection and direct connection types, adaptable to a wide variety of machines.

– These features make TungTurnJet an ideal solution for improving machining stability, productivity, and tool life across diverse machining environments.

Success Stories

IMPROVED TOOL LIFE

ISO-EcoTurn GNMG insert, featuring a unique insert shape with 70° corner angle, provides larger clearances on the insert sides, facilitating smooth chip evacuation. A combination with TungTurnJet high pressure through- coolant system allowed short, consistent chip forms to be generated. Also, optimum coolant delivery close to the cutting point provided significantly reduced tool wear, achieving 1.25 times tool life increase.

| Industry | Engineering |

| Component | Sleeve |

| Material ISO code | |

| Work material | SUS304/X5CrNi18-10 |

| Machine(Spindletype) | CNC Lathe |

| Tool family | External & Face turning |

| Toolcategory | Internal threading |

| Product name | TungTurn-Jet |

| TSR No. | 1656T |