Achieving excellent chip control and high-quality surface finishes in non-ferrous metal machining

Tungaloy Corporation (President: Satoshi Kinoshita, Headquarters: Iwaki, Fukushima) is pleased to announce the addition of the “KS05F” grade for non-ferrous metal machining to its “JS” chipbreaker for finishing and the “JP” chipbreaker for precision finishing.

Overview

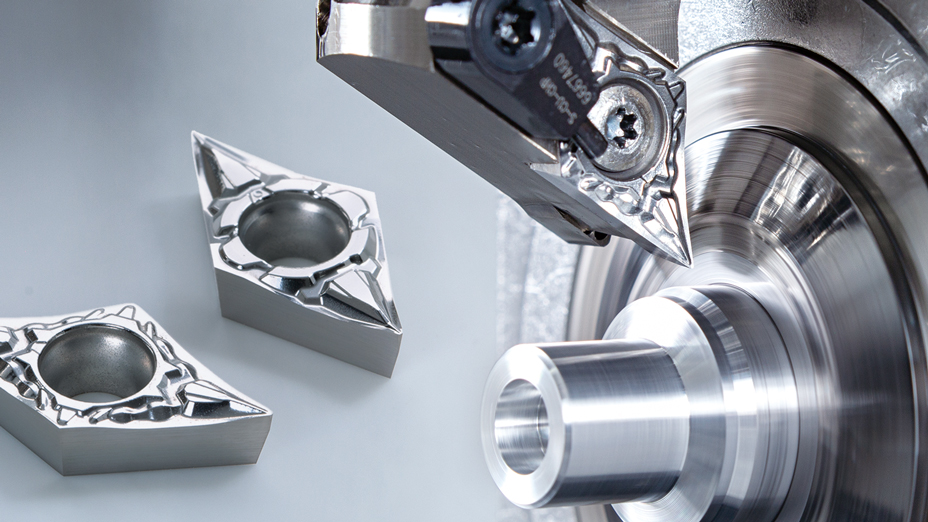

The non-ferrous metal machining series currently includes PCD inserts, along with cemented carbide inserts with positive rake AL-style, negative rake 28-style, and P-style chipbreakers. The new addition of the “KS05F” cemented carbide grade, optimized for non-ferrous metal machining, to the finishing “JS” style chipbreaker and precision finishing “JP” style chipbreaker strengthens the lineup.

The “JS” chipbreaker features a large inclination angle and an optimized chipbreaker geometry, enabling stable chip control across a wide range of cutting conditions, from low to high depth of cuts. The “JP” chipbreaker, with its raised projections near the cutting edge, delivers superior chip control, particularly in precision finishing operations. It also minimizes burr formation under large depth cutting conditions, ensuring stable machining performance.

The “KS05F” cemented carbide grade, designed for non-ferrous metal machining, excels in balancing wear resistance and toughness. The mirror-finished rake face further enhances its resistance to built-up edge. Together, the combination of the “JS” chipbreaker for finishing, the “JP” chipbreaker for precision finishing, and the “KS05F” grade ensures stable machining, reduces chip entanglement and burr formation, and delivers high-quality surface finishes, significantly contributing to the productivity of our customers.

Product information

No. 555S4-G (Metric)

Non-Ferrous Application Series