Online Shop |

Online Shop Learn more |

NTK Website |

NTK Website Learn more |

e-Catalog |

e-Catalog Learn more |

Resources

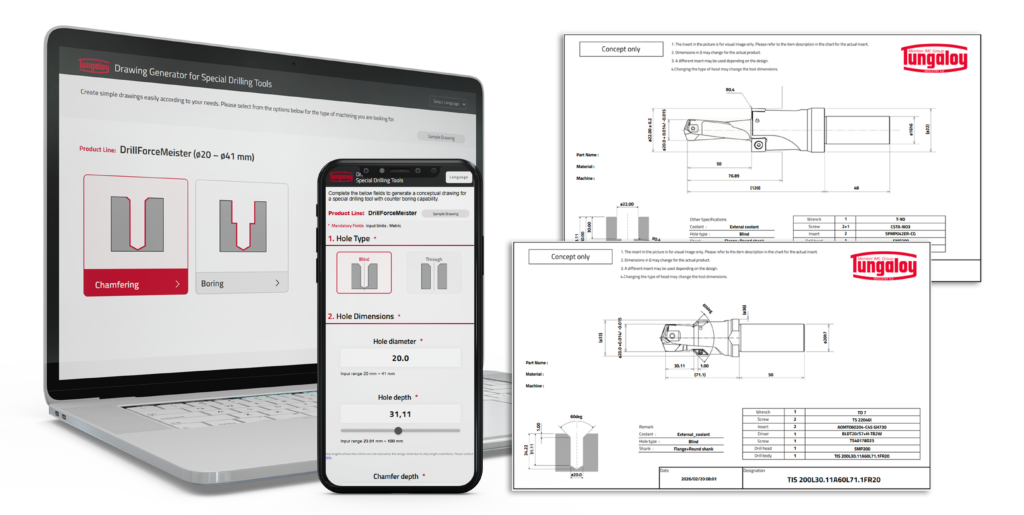

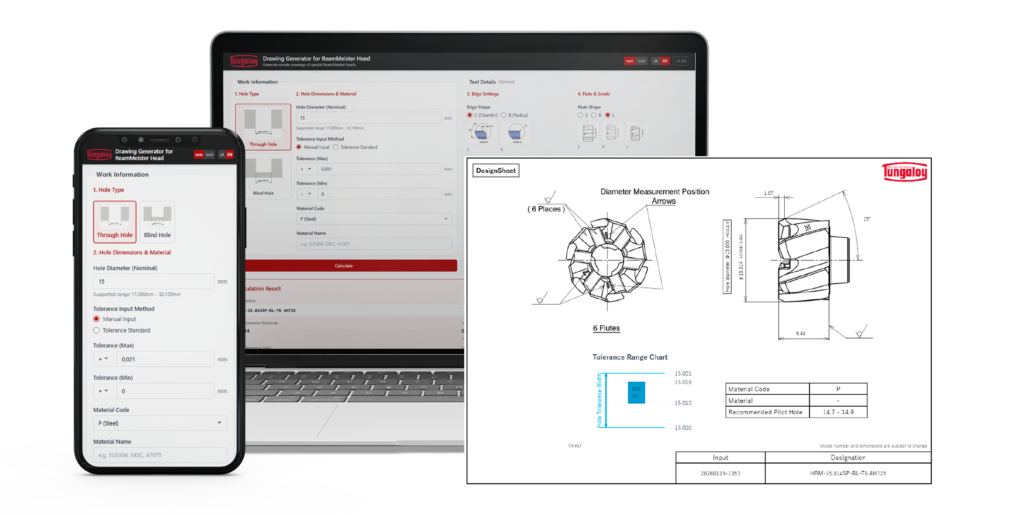

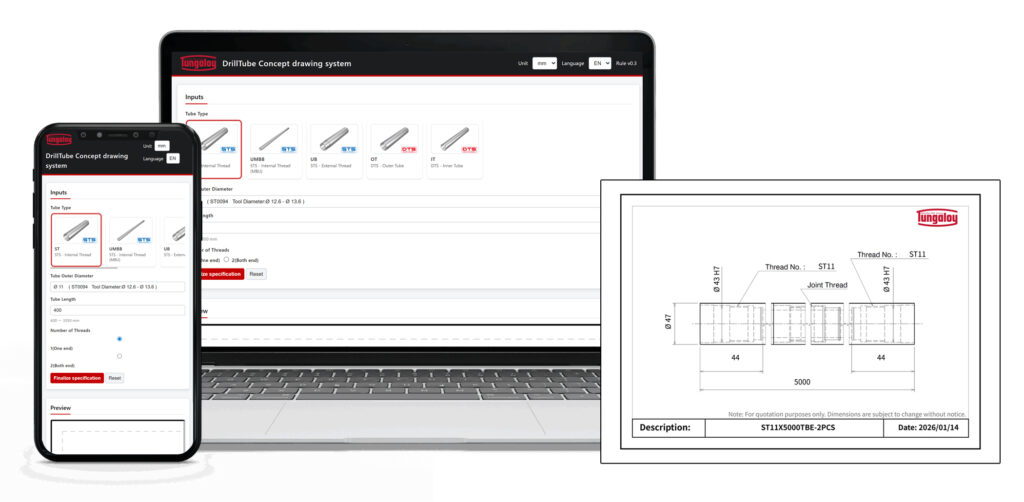

Tungaloy APP

Tungaloy’s new App offers machining solutions for engineers and salespersons.

Learn more

Tungaloy Success Report

Explore Tungaloy’s TSR for custom machining insights with easy search

Learn more

Technical Guides

Access Tungaloy’s technical guides for valuable insights, references, and resources.