Solid carbide boring bar for small-diameter drilling and turning

Boosts productivity for small part machining

Applications & Features

Applications

Features

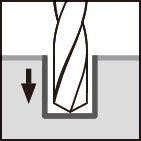

Multifunctional solid carbide boring bar for small-diameter drilling and various turning processes

Optimized design provides maximum tool stiffness during machining

Application ranges of multifunctional drilling and turning tool series

Enables multiple tool combinations and productivity boosts for small part machining

- A single tool for multiple applications

- Allows tool combinations while increasing the number of open slots in the turret or tool posts in your CNC lathes and Swiss machines

- Able to form a flat hole bottom

Solid Carbide Boring Bars & Grades

Solid Carbide Boring Bars

Grades

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- High wear resistance

- Designed for machining steel and stainless steel

Sleeves

Practical examples

Example #1

| Workpiece Type: | Joint |

| Workpiece Material: | SUS316 / X5CrNiMo17-12-3 |

| Toolholder: | JBBS19-7-L100C-4N |

| Insert: | TBMFR0718003-D060 |

| Grade: | SH725 |

| Cutting conditions: | Vc = 30 (m/min) f = 0.04 (mm/rev) Machining: Drilling Coolant: Internal |

Example #2

| Workpiece Type: | Machine part |

| Workpiece Material: | S45C / C45 |

| Toolholder: | JBBS254-7-L100C-4N |

| Insert: | TBMFR0718003-D060 |

| Grade: | SH725 |

| Cutting conditions: | Vc = 70 (m/min) f = 0.02 (mm/rev) ap = 0.8 (mm) Machining: Internal turning Coolant: Internal |

Example #3

| Workpiece Type: | Spacer |

| Workpiece Material: | SUS304 / X5CrNi18-9 |

| Toolholder: | JBBS19-7-L100C-4N |

| Insert: | TBMFR0712001-D060 |

| Grade: | SH725 |

| Cutting conditions: | Vc = Drilling: 30, Turning : 40 (m/min) f = Drilling: 0.015, Turning : 0.03 (mm/rev) ap = Turning : 0.5 (mm) Machining: Drilling, facing and internal turning Coolant: Internal |

Standard cutting conditions

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) | |

|---|---|---|---|---|

| Drilling | Turning | |||

| Low carbon steels S15C, S25C, etc. C15E, C15E4, etc. |

SH725 | 20 – 100 | 40 – 140 | |

| Carbon steels, Alloy steels S55C, SCM440, etc. C55, 42CrMo4, etc. |

SH725 | 20 – 100 | 40 – 140 | |

| Prehardened steels NAK80, PX5, etc. |

SH725 | 20 – 100 | 40 – 140 | |

| Stainless steels SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

SH725 | 20 – 60 | 40 – 140 | |

| Grey cast irons FC250, FCD300, etc. GG25, 250, GG30, 300, etc. |

SH725 | 30 – 100 | 30 – 100 | |

| Ductile cast irons FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 30 – 100 | |

| Aluminium alloys, Copper alloys Si < 12% |

SH725 | 50 – 200 | 90 – 200 | |

| Titanium alloys Ti-6AI-4V, etc. |

SH725 | 20 – 50 | 30 – 100 | |

| Superalloys Inconel718, etc. |

SH725 | 20 – 50 | 30 – 100 | |

L/D=2

| Application range | Minimum bore diameter: DMIN (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ø3 | ø4 | ø5 | ø6 | ø7 | ||||||

| Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|

| Internal and external turning |

0.2 – 1.5 | 0.01 – 0.08 | 0.2 – 2 | 0.01 – 0.08 | 0.2 – 2.5 | 0.01 – 0.08 | 0.2 – 3 | 0.01 – 0.08 | 0.3 – 3.5 | 0.01 – 0.08 |

| Face turning | 0.02 – 0.2 | 0.01 – 0.06 | 0.02 – 0.4 | 0.01 – 0.06 | 0.2 – 0.65 | 0.01 – 0.06 | 0.2 – 0.65 | 0.01 – 0.06 | 0.25 – 0.7 | 0.01 – 0.07 |

| Drilling | – | 0.01 – 0.06 | – | 0.01 – 0.06 | – | 0.01 – 0.08 | – | 0.01 – 0.08 | – | 0.01 – 0.1 |

L/D=3

| Application range | Minimum bore diameter: DMIN (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ø3 | ø4 | ø5 | ø6 | ø7 | ||||||

| Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|

| Internal and external turning |

– | – | 0.2 – 2 | 0.01 – 0.07 | 0.2 – 2.5 | 0.01 – 0.07 | 0.2 – 3 | 0.01 – 0.07 | – | – |

| Face turning | – | – | 0.02 – 0.4 | 0.01 – 0.04 | 0.2 – 0.65 | 0.01 – 0.04 | 0.2 – 0.65 | 0.01 – 0.04 | – | – |

| Drilling | – | – | – | 0.01 – 0.05 | – | 0.01 – 0.06 | – | 0.01 – 0.06 | – | – |

For more information about this product, visit our online e-catalog or download the product report: