Iwaki, Japan – April, 2024 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DrillMeister series, now featuring head-changeable drills from 4.0 mm to 8.4 mm in diameter with 3xD drilling depth, compatible with TinyMiniTurn sleeves for automatic lathes.

Challenges and Trends

In drilling operations using automatic lathes, the tool mounting diameter is restricted, making it common to use sleeves for tool installation. However, with conventional sleeves, the drill overhang must be readjusted during tool changes. This adjustment process is difficult in the limited space inside the machine, leading to poor workability and decreased productivity. These challenges and market conditions have created a demand for more efficient and user-friendly tool solutions.

Product Overview

Newly added a small-diameter DrillMeister body that is compatible with automatic lathe machining. This body can be used with the TinyMiniTurn sleeve.

Benefits and Features

Feature 1: Specialized Design for Automatic Lathes Ensures High Compatibility and Stability

- Compatible with TinyMiniTurn series sleeves, allowing use with existing equipment

- Uses shank diameters dedicated to automatic lathes for high machine compatibility

- Maintains consistent overhang length during tool changes, improving machining accuracy and repeatability

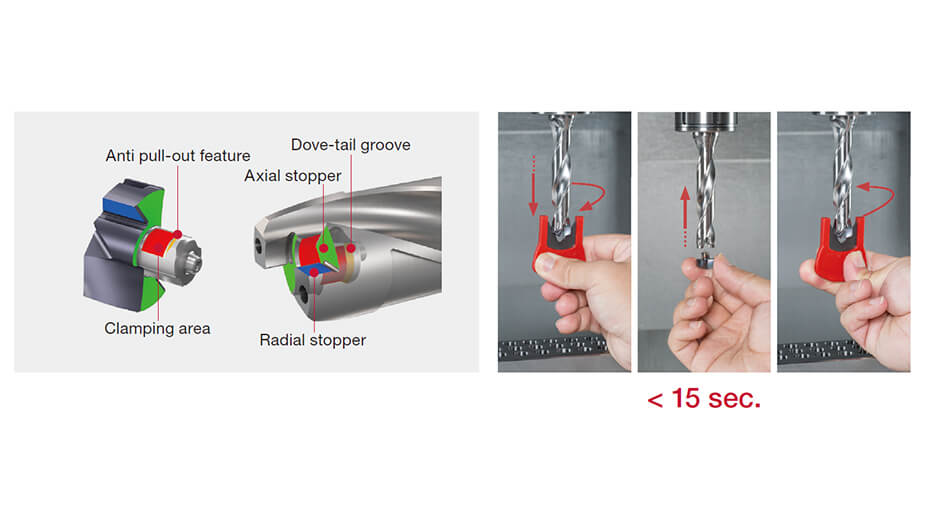

Feature 2: Quick-Change Mechanism for Enhanced Work Efficiency

- Head exchangeable structure enables tool changes in approximately 15 seconds

- Easy replacement even in confined machine interiors, significantly reducing setup time

- Minimizes production line downtime and improves machine utilization

Feature 3: Excellent Chip Control and Machining Stability

- Internal coolant supply ensures reliable lubrication and cooling at the cutting point

- Twisted flute geometry enables stable chip evacuation, even with ductile materials

- Supports drilling depths up to 3xD, meeting a wide range of machining requirements

Feature 4: Wide Range of Head Variations for Versatile Applications

- Compatible with a wide variety of DrillMeister and ADDMeisterDrill heads

- Optimal head selection available based on workpiece material and geometry

- Standardized tool inventory helps reduce management costs

Success Stories

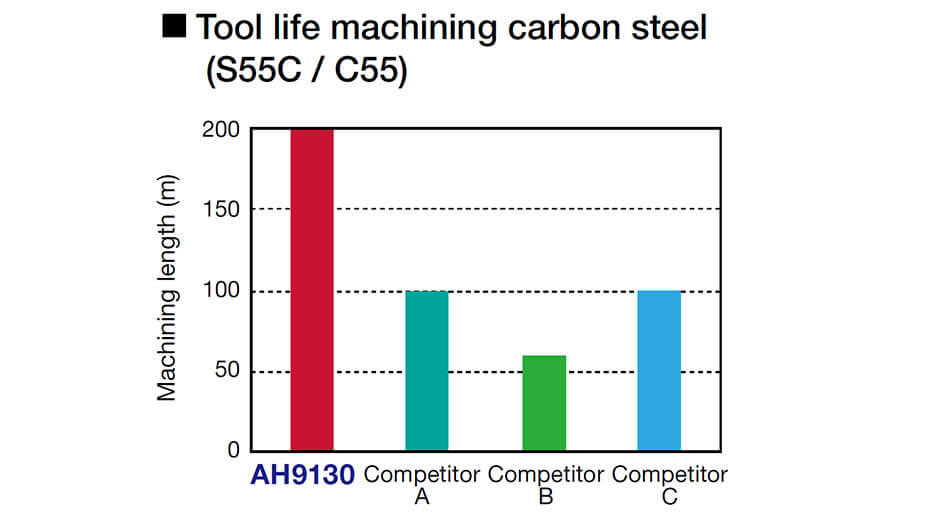

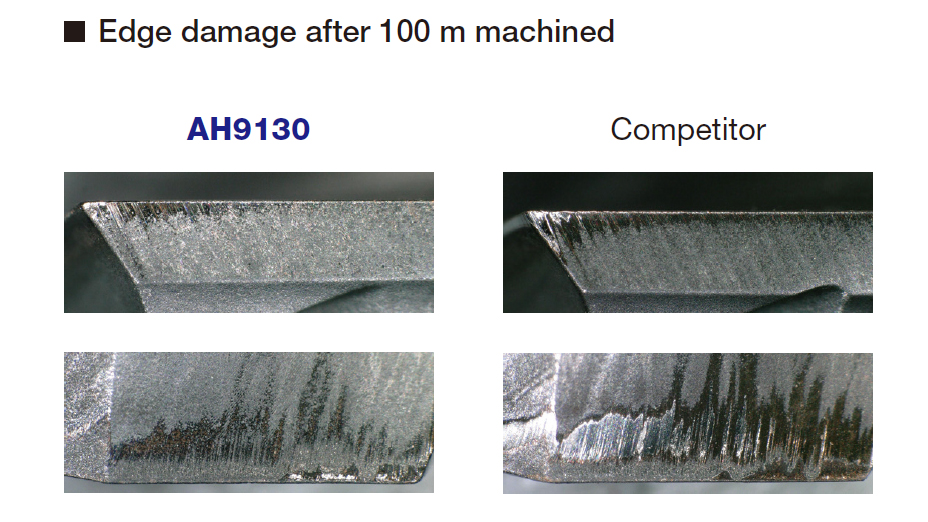

IMPROVED TOOL LIFE

Applied the DMF head. Improved chip disposal performance and enabled enhancement of machining conditions. Achieved 1.6 times tool life by increasing feed rates

| Industry | Miniature |

| Component | Sleeve outter |

| Material ISO code | |

| Work material | S10C |

| Machine(Spindletype) | Swiss Lathe |

| Tool family | Holemaking |

| Toolcategory | Drilling |

| Product name | DrillMeister |

| TSR No. | 5000D |